A method for evaluating the operating range of compressors

A technology of operating range and compressor, which is applied in the field of compressors, can solve problems such as the inability to evaluate the operating range, and achieve the effects of shortening the selection cycle, improving development efficiency, and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

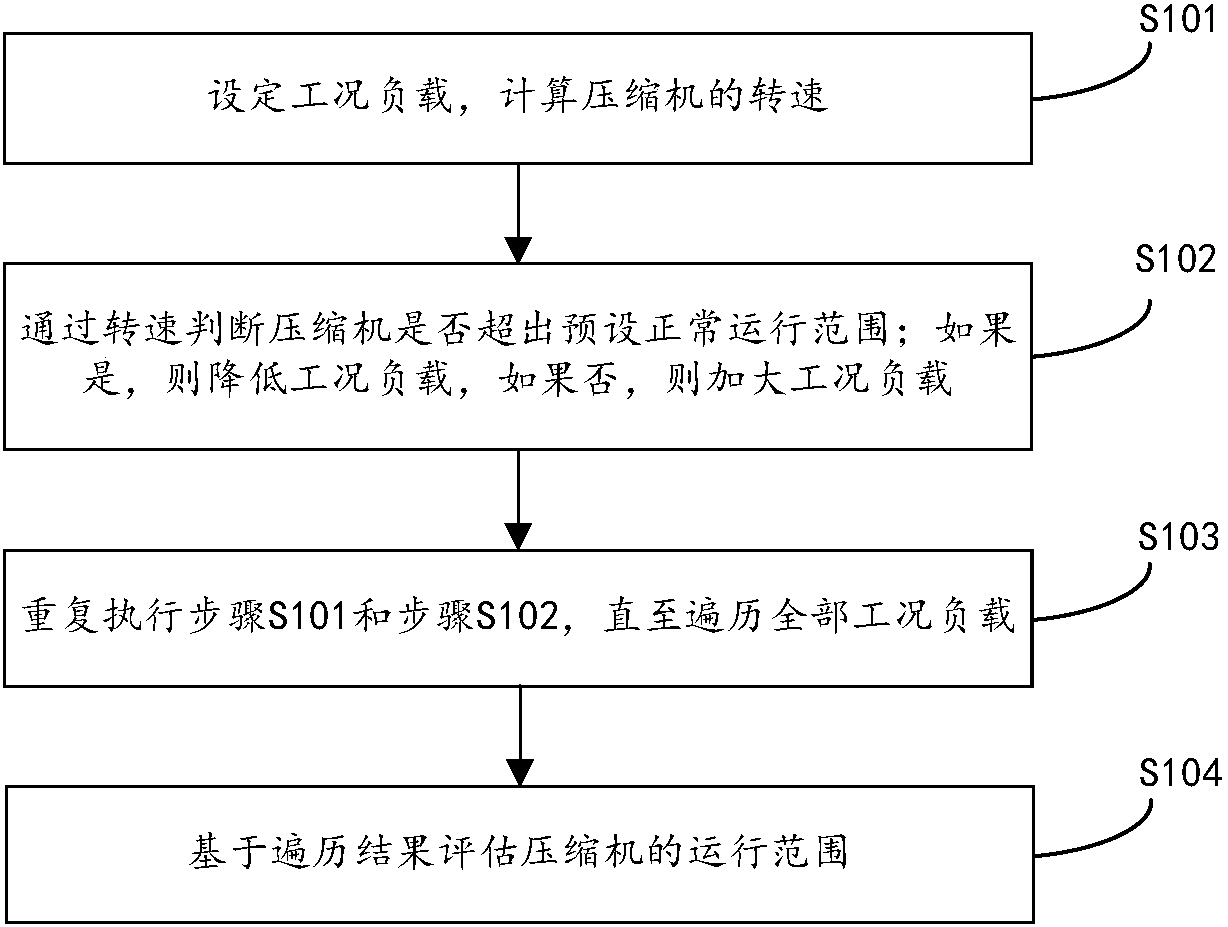

[0015] figure 1 is a flowchart of a method for evaluating the operating range of a compressor according to an embodiment of the present invention, such as figure 1 As shown, the method includes the following steps (step S101-step S104):

[0016] Step S101, setting the working condition load, and calculating the rotational speed of the compressor; wherein, the working condition load in this embodiment includes at least one of the following: the evaporating temperature, the condensing temperature, and the suction temperature of the compressor;

[0017] Specifically, this step can be realized through the following preferred procedure: acquiring the discharge temperature of the compressor and the motor torque; calculating the rotational speed of the compressor according to the motor torque. Thereby providing a basis for subsequent judgment based on the rotation speed whether the compressor is beyond the preset normal operation range.

[0018] Step S102, judging whether the compr...

Embodiment 2

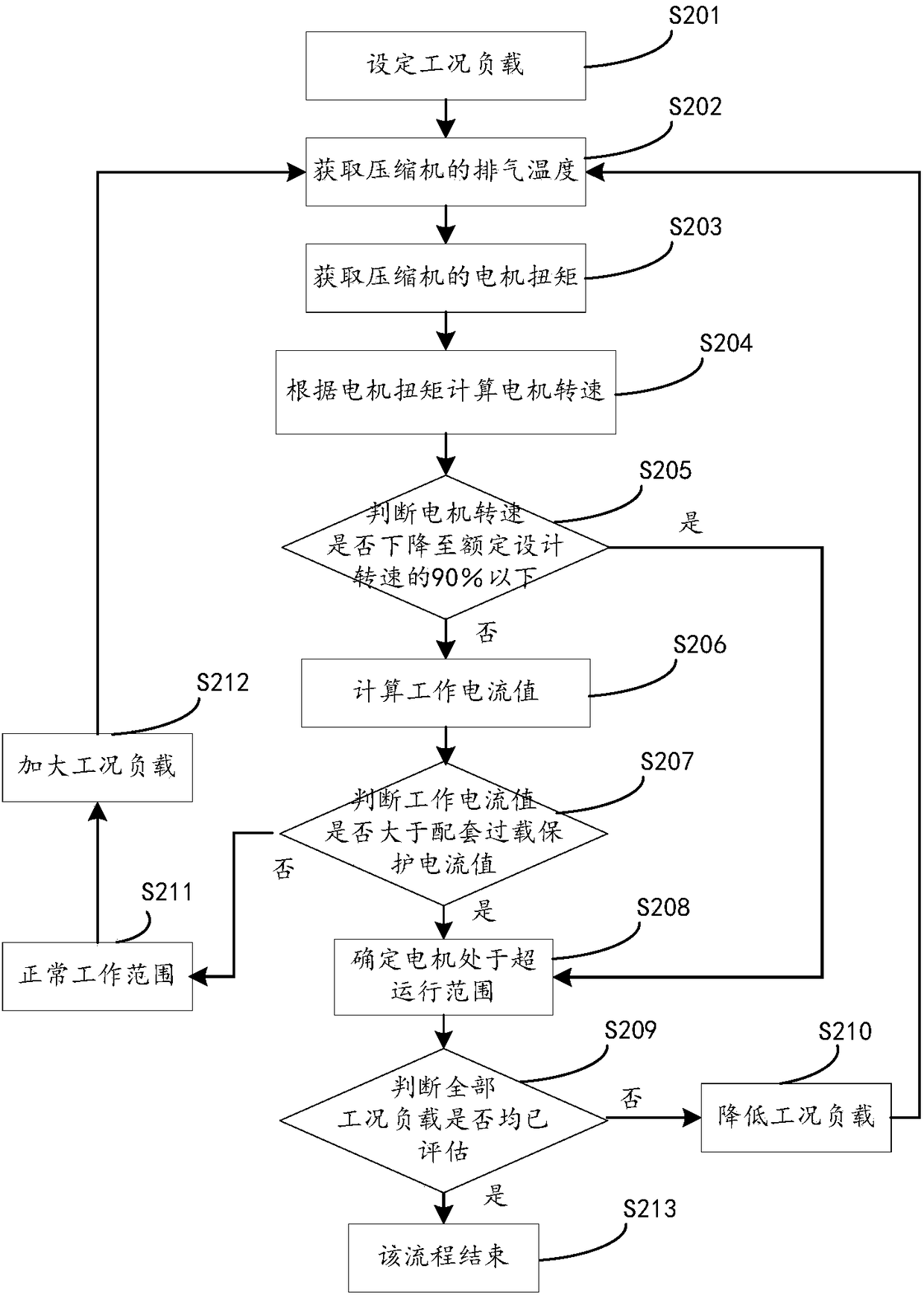

[0025] figure 2 is a flowchart of a compressor evaluation method according to an embodiment of the present invention, such as figure 2 As shown, the method includes the following steps (step S201-step S213):

[0026] Step S201, setting the working condition load. The working condition load includes at least one of the following: evaporating temperature, condensing temperature, and suction temperature of the compressor.

[0027] Step S202, acquiring the discharge temperature of the compressor.

[0028] Step S203, acquiring the motor torque of the compressor.

[0029] Specifically, according to the principle of refrigeration and the pressure-enthalpy diagram, after the evaporation temperature, condensation temperature, and suction temperature of the compressor are determined, the discharge temperature of the compressor can be obtained from the characteristics of the refrigerant, and the required motor torque.

[0030] In this embodiment, the execution order of step S202 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com