Supporting structure for zero distance underneath pass of existing station of rectangular tunnel section and construction method

A technology of existing stations and supporting structures, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of difficult recovery of superstructure, large deformation, unable to meet the needs of subway engineering development, etc., and achieve the effect of reducing investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in combination with specific embodiments.

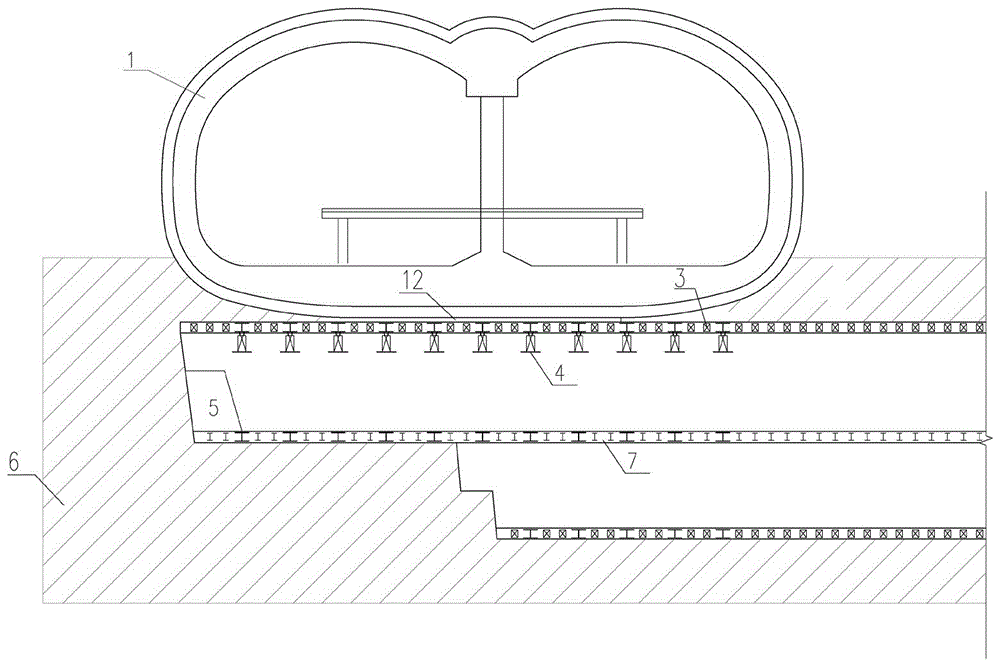

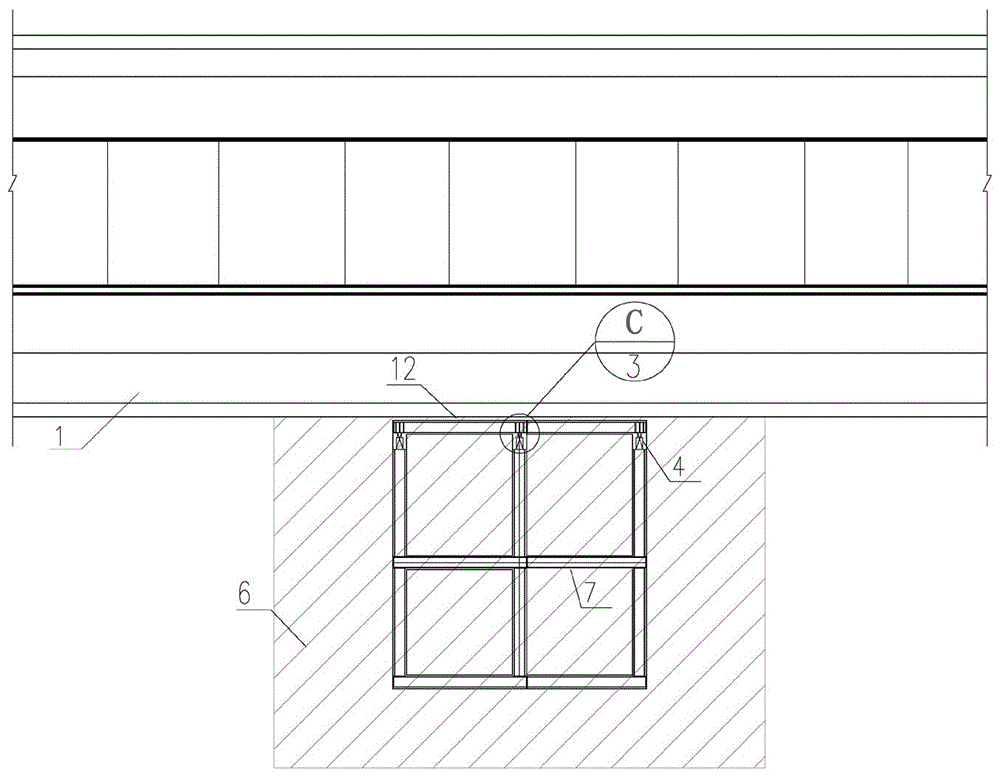

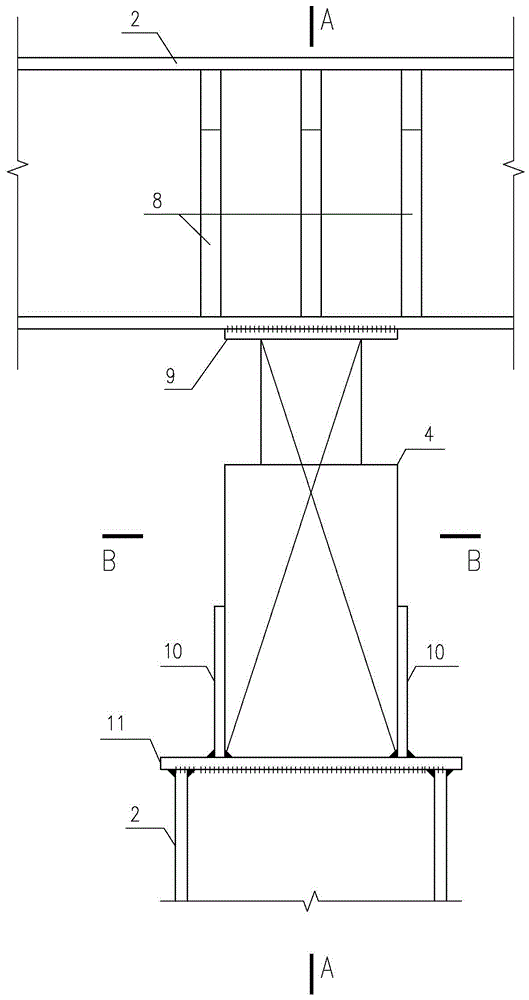

[0036] The present invention relates to a support structure for a rectangular tunnel cross-section passing through an existing station at zero distance. Before excavation of a mine tunnel, a deep hole grouting reinforcement 6 is applied to the face of the tunnel, and the core soil is reserved by ring excavation. Excavate the upper and lower pilot tunnels on the inner and outer sides of the left and right lines symmetrically, and implement the initial support 7 in time. Install 1 jack 4+shaped steel frame 3 at the bottom of the existing station 1, every 3 grid steel frames longitudinally. Three sets of 100t hydraulic self-locking jacks 4 are installed in each mileage section of the line. When excavating, erect the vertical section steel frame 3 of the side wall first, and weld the connecting bars; The installation method of the parts is as follows: Figure 4 shown. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com