A curd-shaped co3(po4)2/chloroperoxidase hybrid nanoreactor and its application

A technology of chloroperoxidase and chloroperoxide, which is applied in the direction of oxidoreductase, chemical instruments and methods, enzymes, etc., can solve problems such as application obstacles and poor stability, and achieve improved tolerance, good compactness, The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

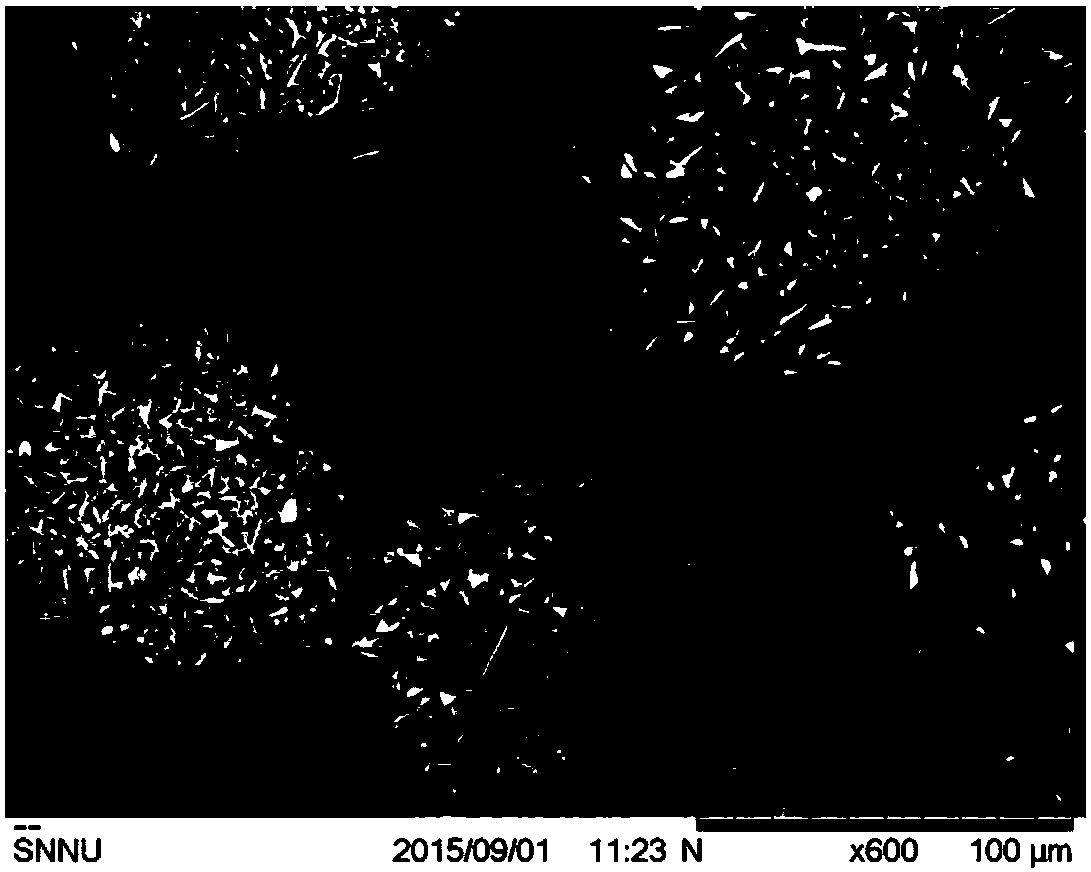

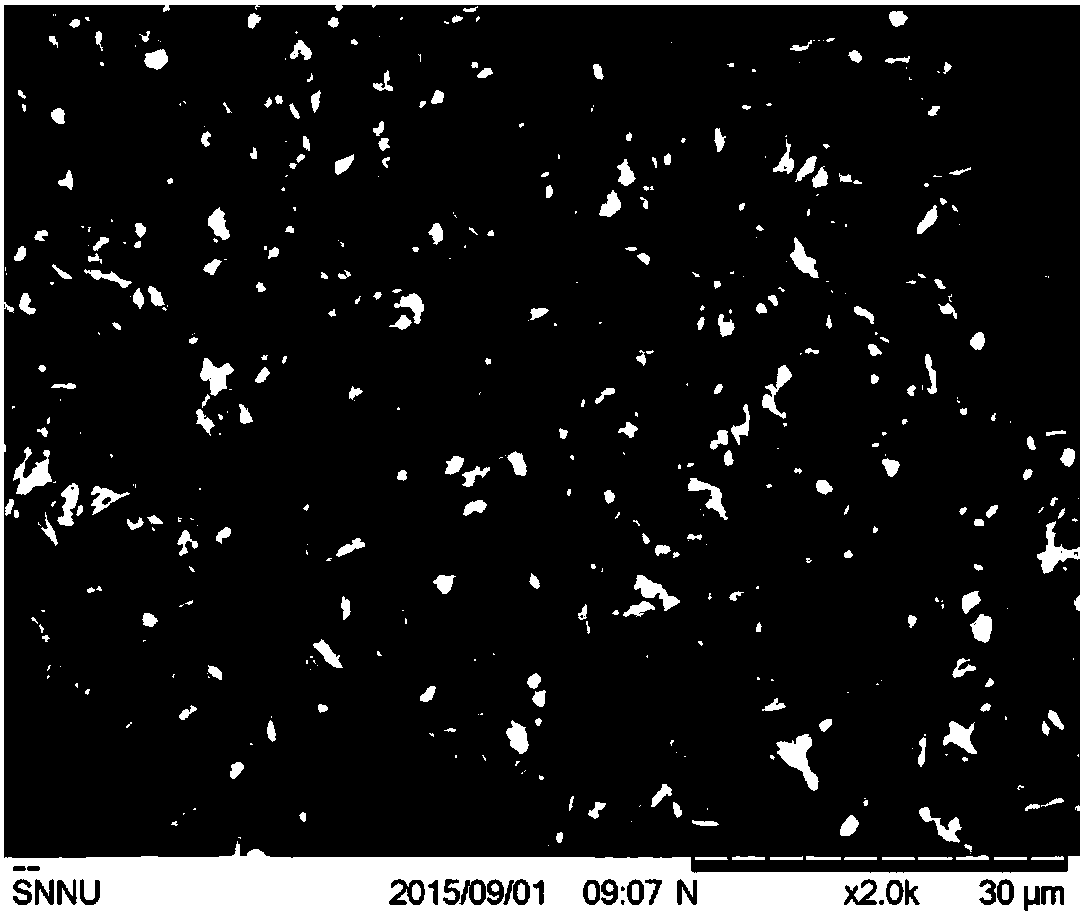

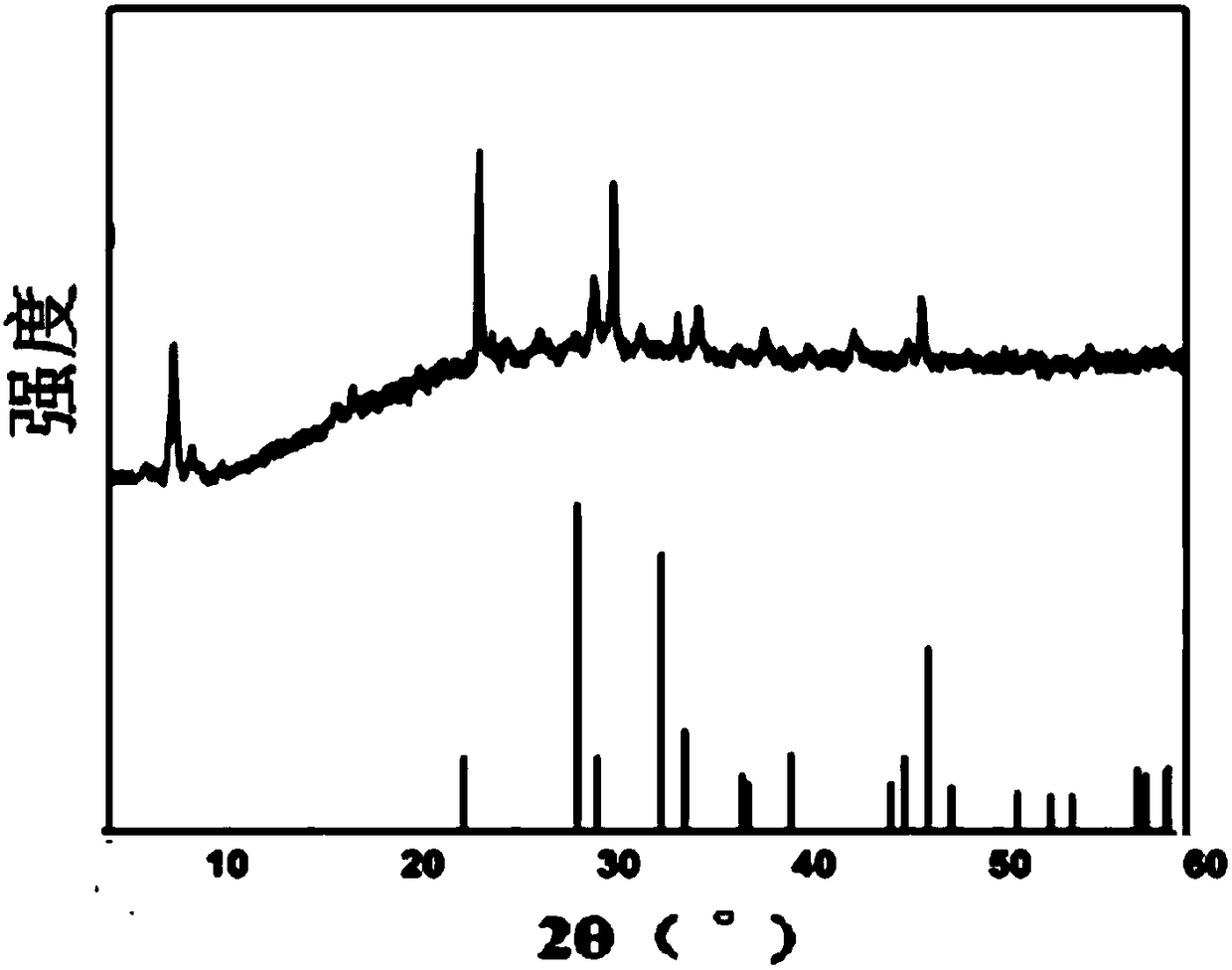

[0021] Add 25μL 0.2mmol / L chloroperoxidase aqueous solution and 600μL 0.1mmol / L cobalt acetate aqueous solution to 9.375mL0.1mol / L phosphate buffer solution with a pH value of 5.8, mix well, and the chloroperoxidase in the resulting mixture The concentration of cobalt acetate is 0.5μmol / L, the concentration of cobalt acetate is 6mmol / L, and then the resulting mixture is placed in a constant temperature incubator at 20°C for 3 days, then the supernatant is removed, and then placed in a vacuum oven at 32°C dried under vacuum to obtain flower-like Co 3 (PO 4 ) 2 / chloroperoxidase hybrid nanoreactor.

Embodiment 2

[0026] Add 25μL 0.1mmol / L chloroperoxidase aqueous solution and 500μL 0.1mmol / L cobalt acetate aqueous solution to 9.475mL0.1mol / L phosphate buffer solution with a pH value of 3, mix well, and the chloroperoxidase in the resulting mixture The concentration of cobalt acetate is 0.25μmol / L, the concentration of cobalt acetate is 5mmol / L, and then the resulting mixture is placed in a constant temperature incubator at 20°C for 3 days, then the supernatant is removed, and then placed in a vacuum oven at 32°C dried under vacuum to obtain flower-like Co 3 (PO 4 ) 2 / chloroperoxidase hybrid nanoreactor, wherein the immobilized amount of chloroperoxidase is 45.7mg / g.

Embodiment 3

[0028]Add 30 μL of 0.2 mmol / L chloroperoxidase aqueous solution and 900 μL of 0.1 mmol / L cobalt acetate aqueous solution to 9.070 mL of 0.1 mol / L phosphate buffer solution with a pH value of 5, mix well, and the chloroperoxidase in the resulting mixture The concentration of cobalt acetate is 0.6μmol / L, the concentration of cobalt acetate is 9mmol / L, and then the resulting mixture is placed in a constant temperature incubator at 20°C for 3 days, then the supernatant is removed, and then placed in a vacuum oven at 32°C dried under vacuum to obtain flower-like Co 3 (PO 4 ) 2 / chloroperoxidase hybrid nanoreactor, wherein the immobilized amount of chloroperoxidase is 50.6mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Loading capacity | aaaaa | aaaaa |

| Loading capacity | aaaaa | aaaaa |

| Loading capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com