Automatic tube packaging machine

A packaging machine and automatic threading technology, applied in packaging, transportation and packaging, single objects, etc., can solve the problems of lower product packaging yield, acupuncture needle tube wall conflict, acupuncture needle bending, etc., to improve effective work and avoid waste , the effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

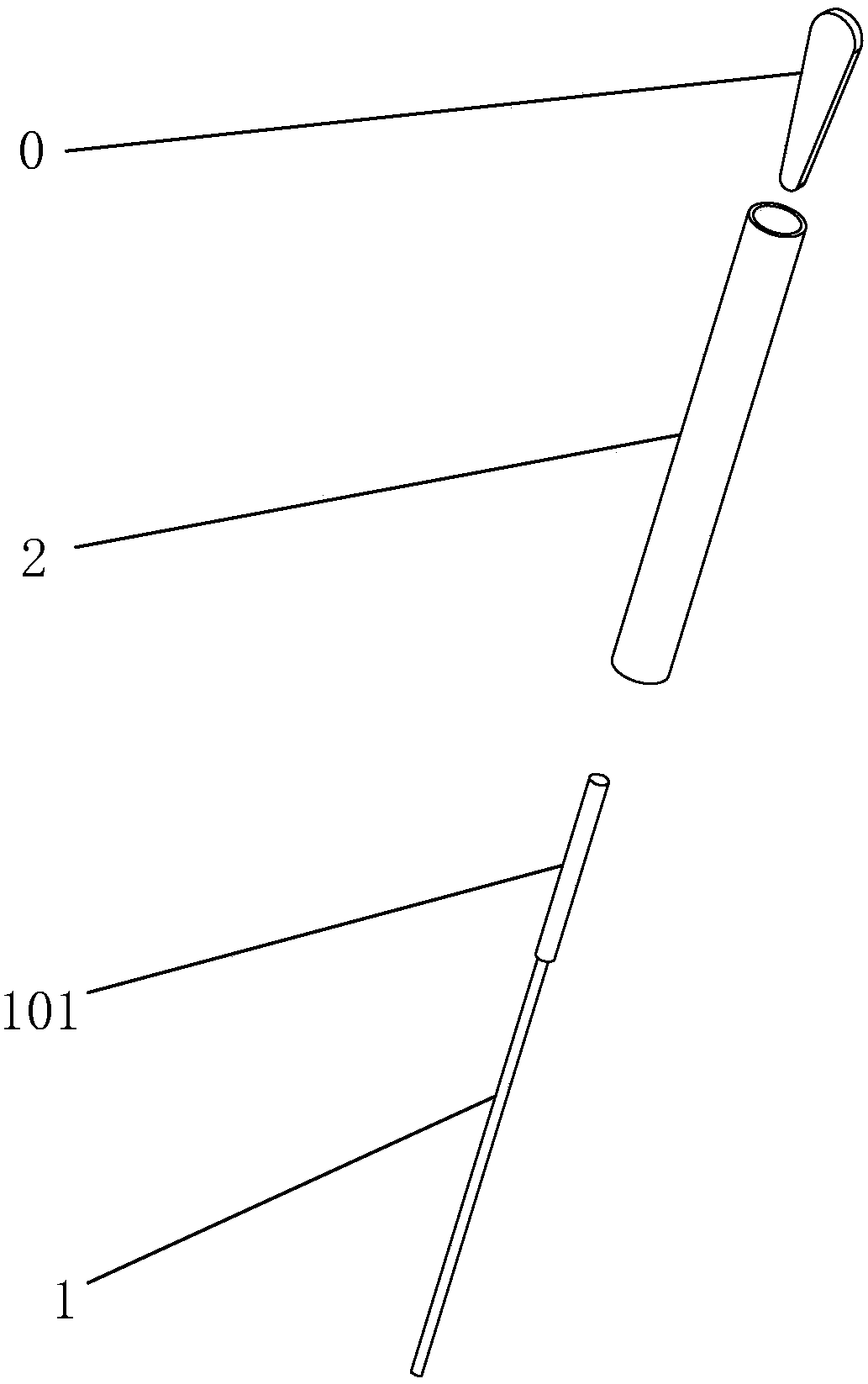

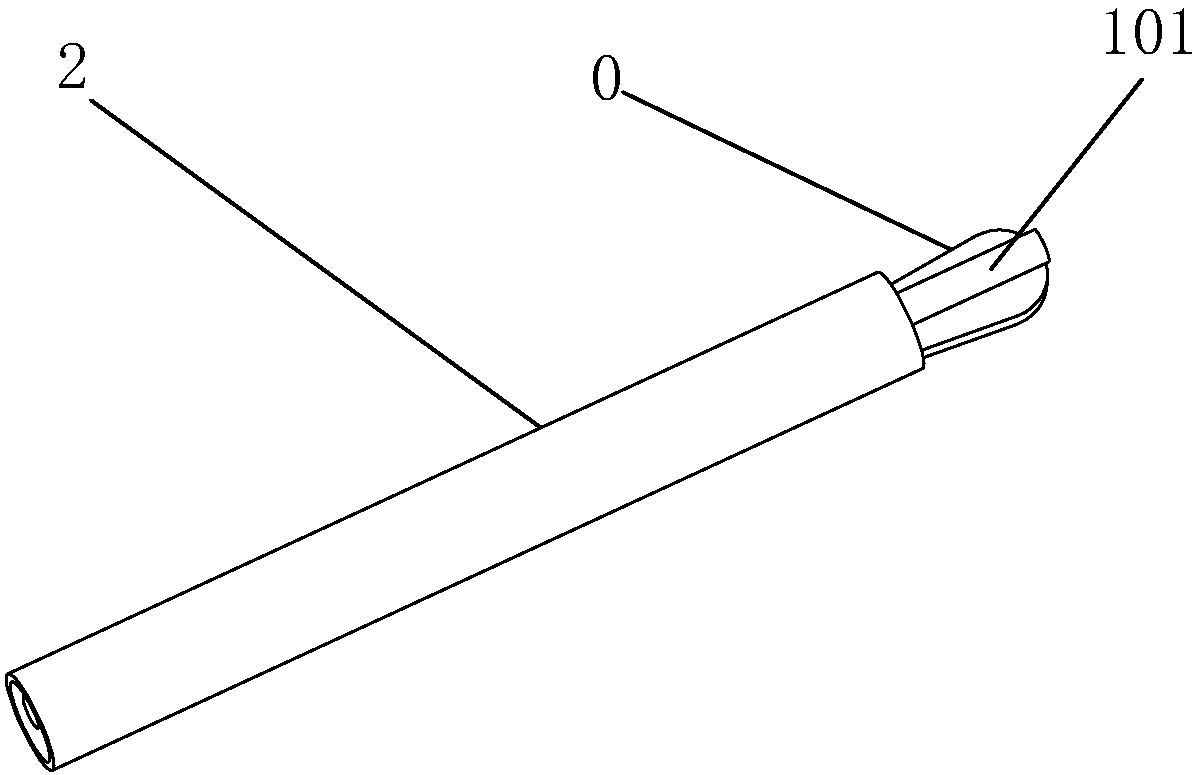

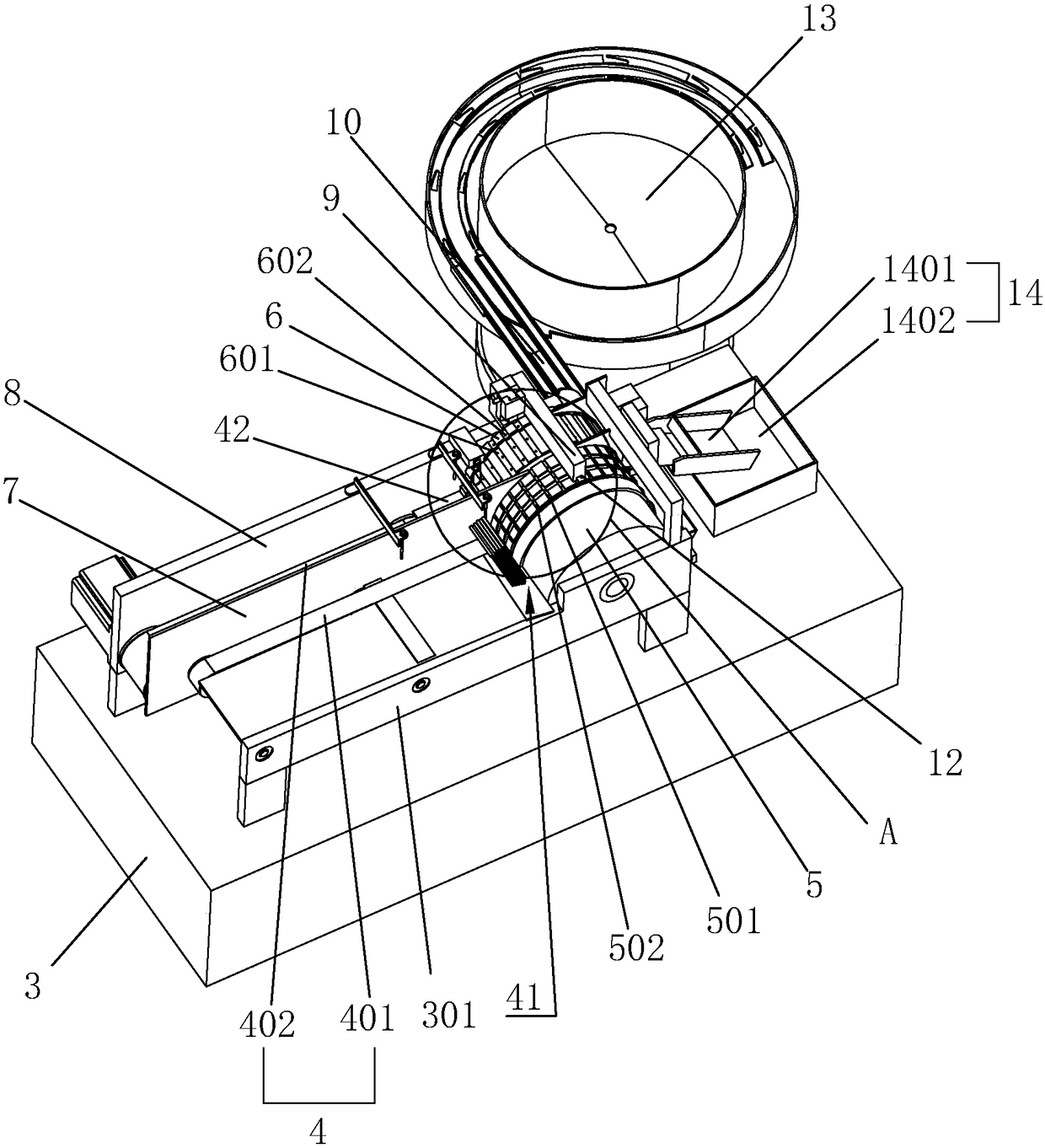

[0039] Embodiment one: an automatic tube-through packaging machine, such as image 3 with Figure 7 As shown, the packaging machine body 3 is included, and the packaging machine body 3 includes a horizontally arranged workbench 301. The workbench 301 is provided with a conveyor belt assembly 4 for conveying acupuncture needles 1 and plastic tubes 2, a needle delivery mechanism and a tube delivery mechanism. The conveyor belt assembly 4 transports the acupuncture needles 1 and the plastic tube 2 to the needle feeding mechanism and the tube feeding mechanism separately. The tube delivery belt 402 is a conveyor belt made of rubber material. The needle delivery belt 401 is used to transport acupuncture needles 1. The needle delivery belt 401 extends from the left end of the workbench 301 to the right end where the needle delivery mechanism is located, and places a cluster of acupuncture needles 1 On the needle belt 401, the workbench 301 is provided with a first driver (not shown...

Embodiment 2

[0053] Embodiment 2: a kind of automatic tube-through packaging machine, such as Image 6 As shown, the difference from Embodiment 1 is that the number of guide plates is 2, which are respectively located above the two sides of the tube delivery wheel 6, and the inclination direction of the two guide plates is the same as that of the guide plates in Embodiment 1. In this embodiment, the distance between the two guide plates is greater than the length of the plastic pipe 2, and less than the sum of the lengths of the feed pipe and the pipe delivery groove 601, wherein one end of the plastic pipe 2 is always connected to the guide plate on the left side of the pipe delivery wheel 6. Contact, the setting of two guide plates, restricts the plastic pipe 2 from breaking away from any end in the pipe delivery groove 601.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com