All-steel tire side automatic positioning code printer

An automatic positioning and tire technology, applied in typewriters, printing and other directions, can solve problems such as increasing tire production costs, and achieve the effect of reducing enterprise production costs and improving the degree of coding automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

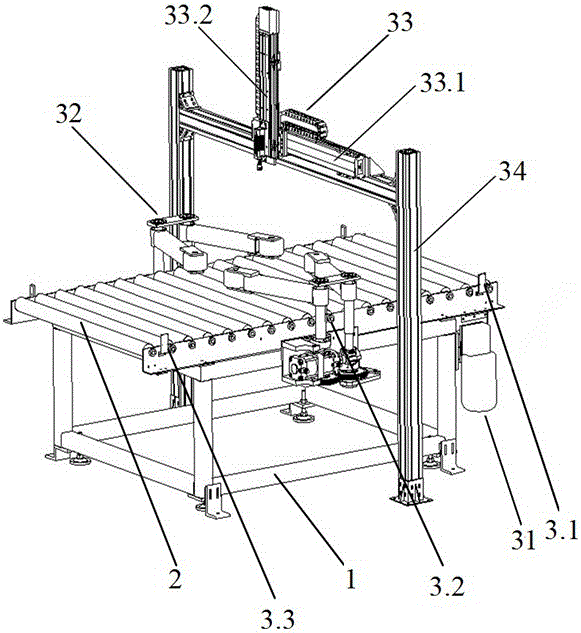

[0050] figure 1 It is a schematic diagram of the structure of the automatic positioning and coding device for the all-steel tire sidewall of the present invention. Such as figure 1 As shown, the automatic positioning and coding device for all-steel tire sidewalls of the present invention of the present invention includes a base frame 1, a transmission mechanism 31, a centering mechanism 32, a photoelectric switch, a gantry 34, a two-axis moving manipulator 33, a coding mechanism, Ultrasonic sensor 19 and travel switch 18.

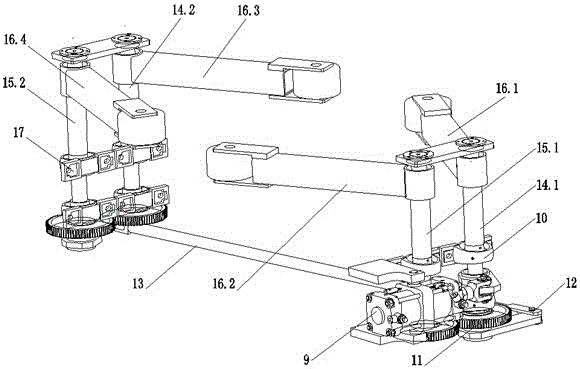

[0051] Specifically: such as figure 2 As shown, the centering mechanism is installed on the base frame to clamp the tires transported by the conveying mechanism; as an embodiment of the present invention, the centering mechanism includes: a rotating arm for For clamping the tire, the rotating arm includes a first rotating arm 16.1, a second rotating arm 16.2, a third rotating arm 16.3, and a fourth rotating arm 16.4; a rotating system is used to drive the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com