Intelligent collaborative dual-arm robot

A robot and dual-arm technology, applied in the field of robotics, can solve the problems of limiting the movement space of the front arm, the absence of wire tubes, and the increase in the width direction of the front arm, so as to improve the degree of freedom and flexibility, prevent wire winding, increase the The effect of working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

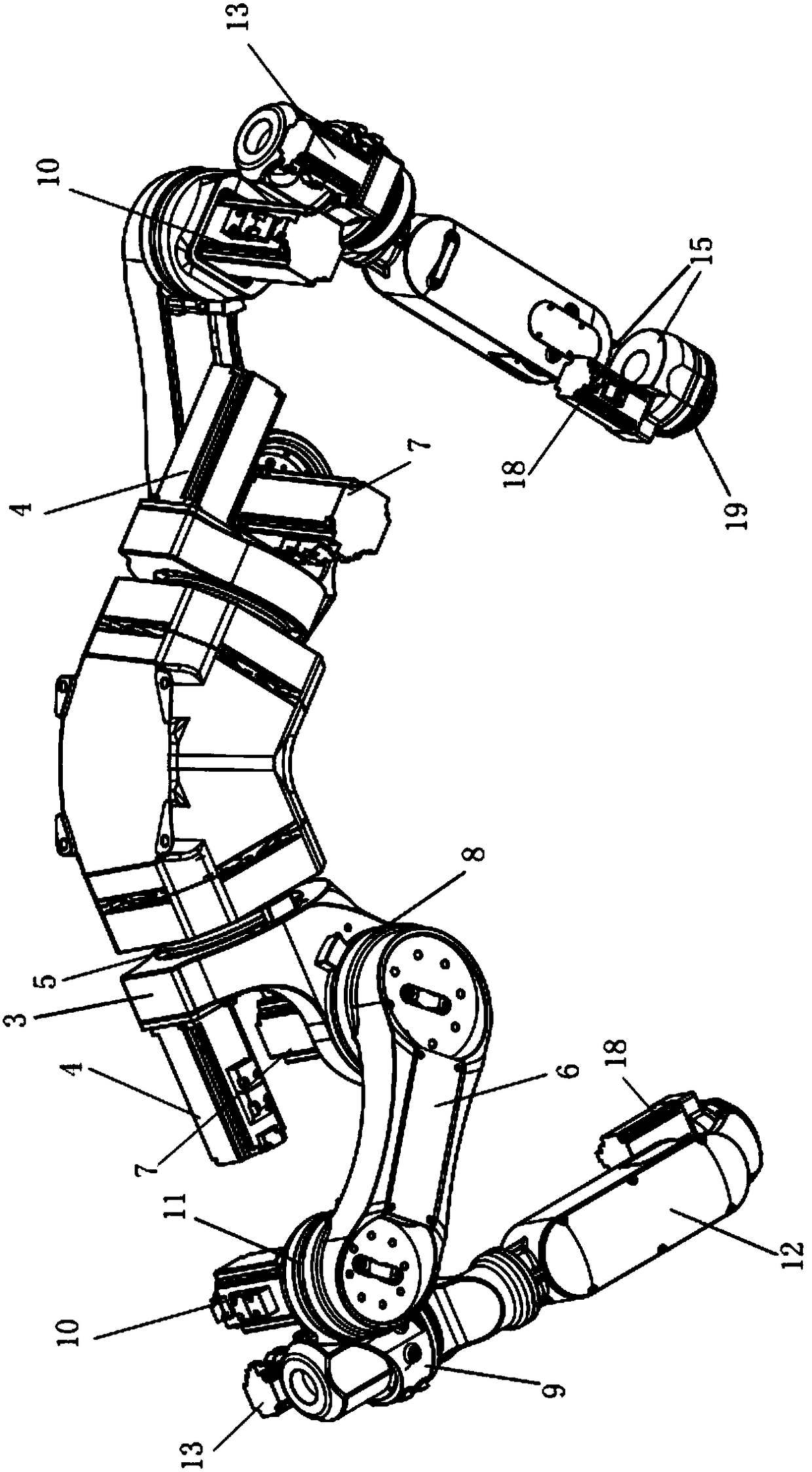

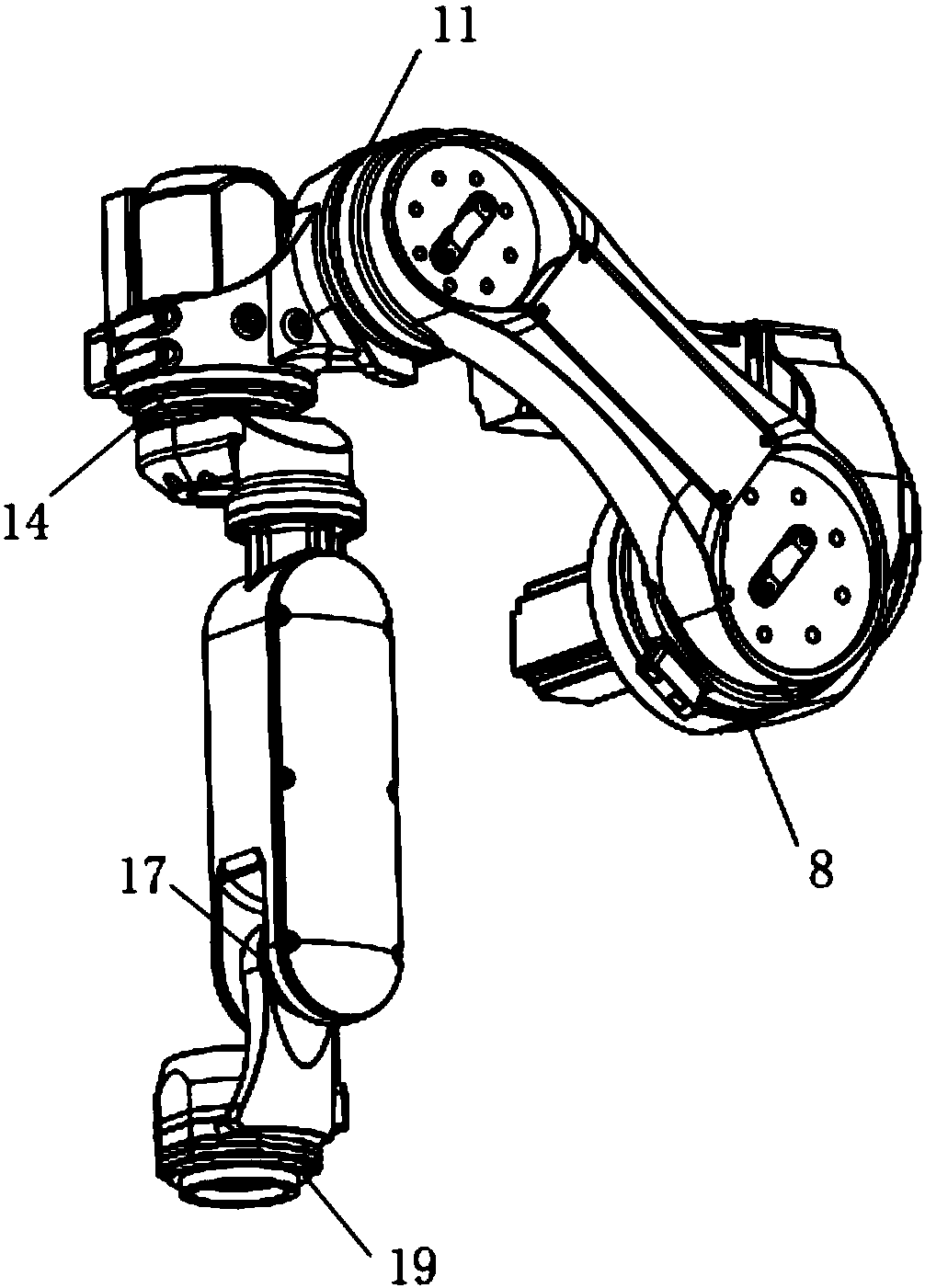

[0054] In this embodiment, the following is described by taking the end effector as an example of a welding torch.

[0055] Such as Figures 1 to 10 As shown, an intelligent collaborative dual-arm robot of the present invention includes a mounting base 1 and two arms, and the two arms are mirror-symmetrically arranged on both sides of the mounting base 1; each arm includes a shoulder-arm assembly and a rear-end arm assembly connected in sequence , an elbow arm assembly, a front end arm assembly and a wrist arm assembly for connecting end effectors. Wherein, one end of the shoulder arm assembly is connected to the mounting base 1 and can rotate around the mounting base 1; one end of the rear end arm assembly is rotatably connected to the side of the other end of the shoulder arm assembly; one end side of the elbow arm assembly is connected to the side of the rear end arm assembly The other end is rotatably connected; one end of the front arm assembly is connected to the other ...

Embodiment 2

[0068] The only difference between this embodiment and the first embodiment is that the end effector can be a processing part such as a wire feeder, which is used for handling, installing, welding, spraying and other operations on materials.

[0069] Other structures of this embodiment are consistent with Embodiment 1.

Embodiment 3

[0071] The difference between this embodiment and the first embodiment is that the angle θ between the two ends of the base is 120°, and the angle β between the centerlines of the shoulders and arms rotating around the base is also 120°.

[0072] Other structures of this embodiment are consistent with Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com