Mechanical part box convenient to move and transport

A technology for mechanical parts and boxes, applied in the field of mechanical parts boxes, can solve the problems of inconvenience, inconvenience, and large occupied area, and achieve the effects of easy moving and transportation, saving occupied area, and convenient access.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

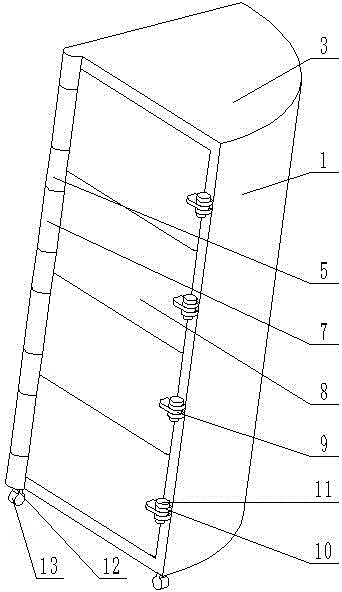

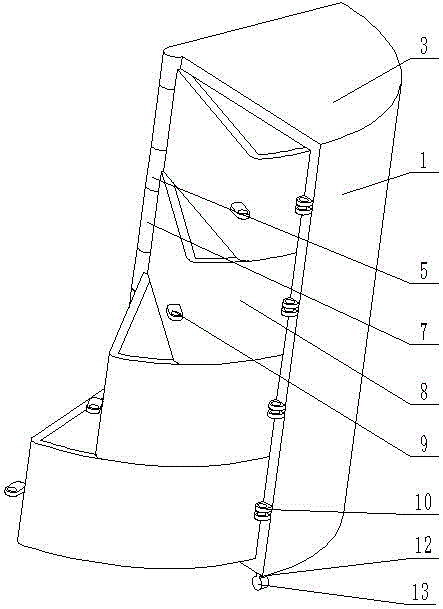

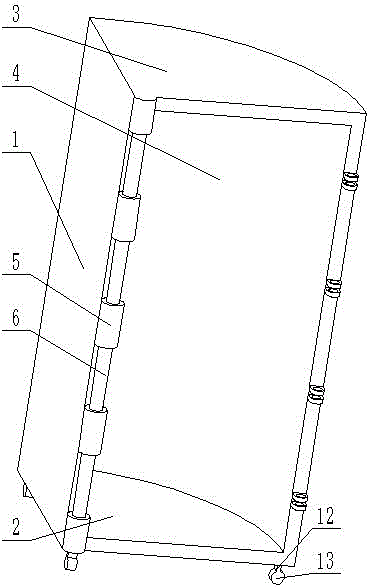

[0023] Mechanical parts box for easy mobile transportation, see Figure 1-5 :

[0024] The connection cylinder 7 is provided with a connection fitting hole 7-1.

[0025] The rotary glove box 8 is provided with a dividing plate 8-1 and a storage tank 8-2, and there is one dividing plate 8-1, and a dividing plate 8-1 divides the rotating glove box 8 into two storage tanks 8-2.

[0026] The connecting piece 9 is provided with a fixing hole 9-1.

[0027] The damping connector 12 is provided with a damping matching groove 12-1, a damping spring 12-2, a limit stop ring 12-3, a movable connecting rod 12-4 and a slide block 12-5, and the damping spring 12-2 It is arranged inside the shock-absorbing fitting groove 12-1. The limit stop ring 12-3 is arranged at the bottom end of the shock-absorbing matching groove 12-1. The movable connecting rod 12-4 is movably connected inside the shock-absorbing fitting groove 12-1 through the slider 12-5, and is located at the lower end of the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com