Concentricity calibrating device and method for assembling of azimuth compass repeater

A calibration device and technology of concentricity, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult to precisely control the matching clearance of the transmission mechanism, high processing cost, unable to guarantee the four-center coincidence accuracy, etc., to avoid concentricity. The accuracy of the accuracy is not up to standard, the number of rework is reduced, and the processing cycle is shortened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

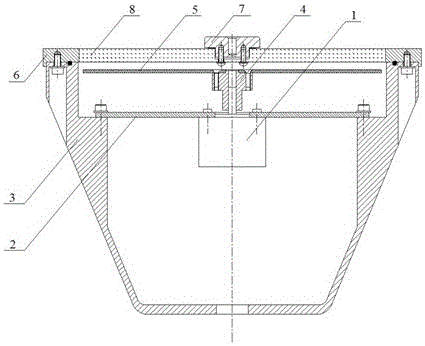

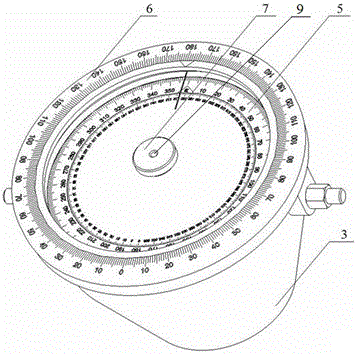

[0048] Such as Figure 1-16 As shown, this embodiment is used for the concentricity calibration device for the assembly of the azimuth compass. The assembly structure of the azimuth compass is: the drive motor 1 is fixed on the casing 3 through the base plate 2, and the drive motor 1 drives the dial through the transmission mechanism 4. 5 rotates, the side angle ring 6 is fixed on the casing 3, and the positioning block 7 is fixed on the side angle ring 6 through the observation glass 8;

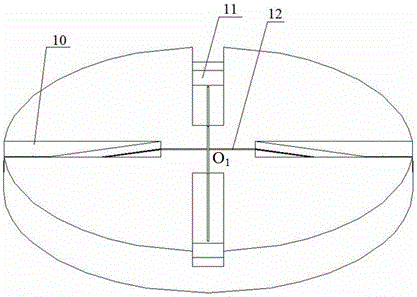

[0049]The concentricity calibration device includes a first calibration unit, a second calibration unit and an optical azimuth 19, and the first calibration unit is used to calibrate the concentricity between the scale center of the side angle ring 6 and the center hole 9 of the positioning block 7 degree, the first calibration unit is a cylinder, and at least four inverted trapezoidal grooves 10 are arranged on the upper end surface of the cylinder, and the four inverted trapezoidal grooves...

Embodiment 2

[0067] This embodiment is used for the concentricity calibration device assembled by the azimuth compass. In this embodiment, the number of inverted trapezoidal grooves in the first calibration unit is 6, and the corresponding observation holes are 6. The first calibration unit is used for When calibrating the concentricity between the scale center of the sheer angle circle and the center hole of the positioning block, observe the scale of the sheer angle circle through 6 observation holes to improve the calibration accuracy, or set the inverted trapezoidal groove in the first calibration unit The number is set to 9, and the corresponding observation holes are 9, or a greater number of inverted trapezoidal grooves and observation holes are required for more precision, so as to optimize the calibration accuracy, and other technical solutions are the same as in Example 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com