Lithium battery casing stretch forming machine

A molding machine and lithium battery technology, applied in the direction of molding tools, storage devices, metal processing equipment, etc., can solve the problems of improving the economic benefits of enterprises with unfavorable production line layout, increasing high-power stamping equipment, and increasing the overall cost volume. Achieve the effects of convenient assembly and use, high safety in use, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

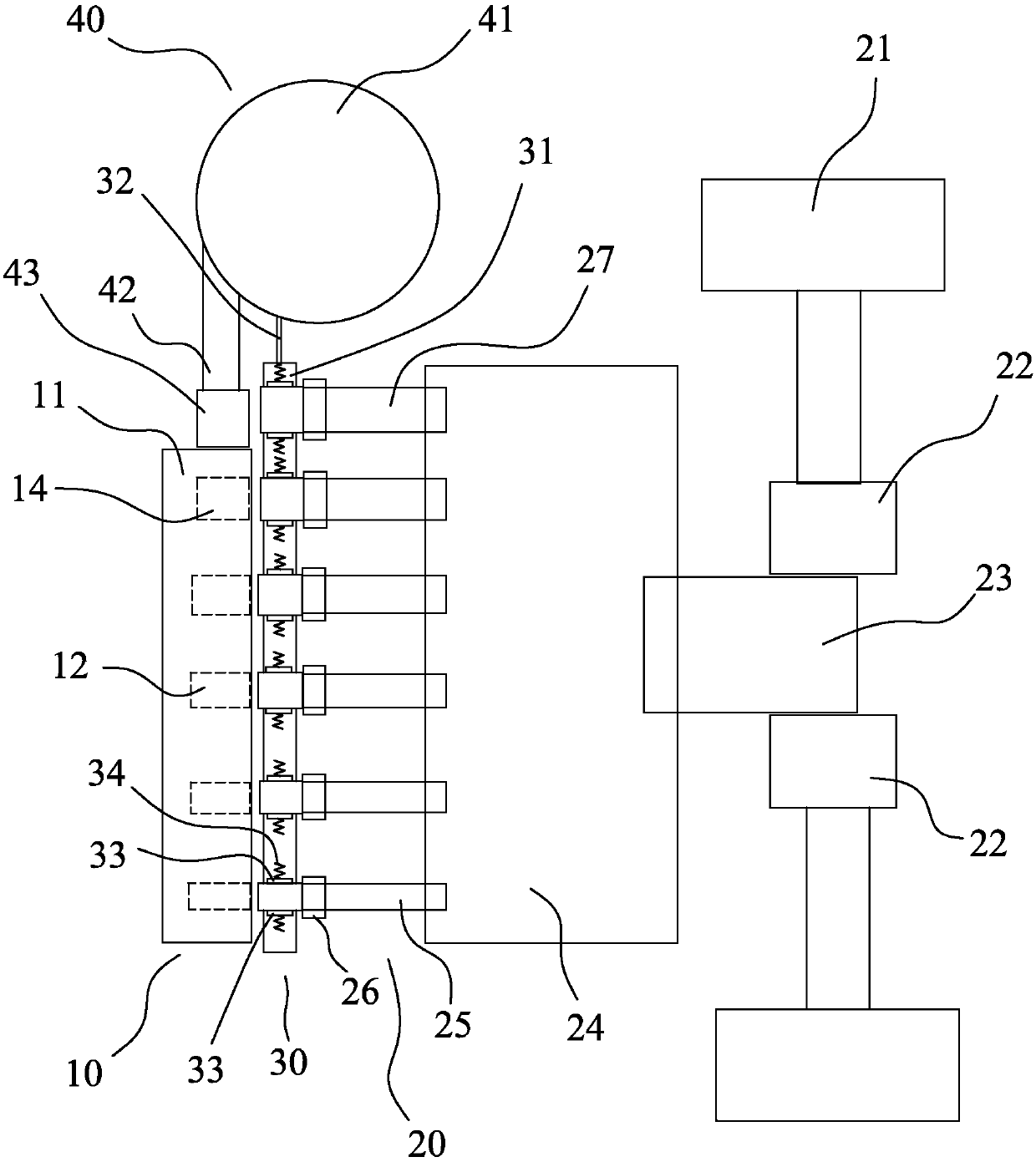

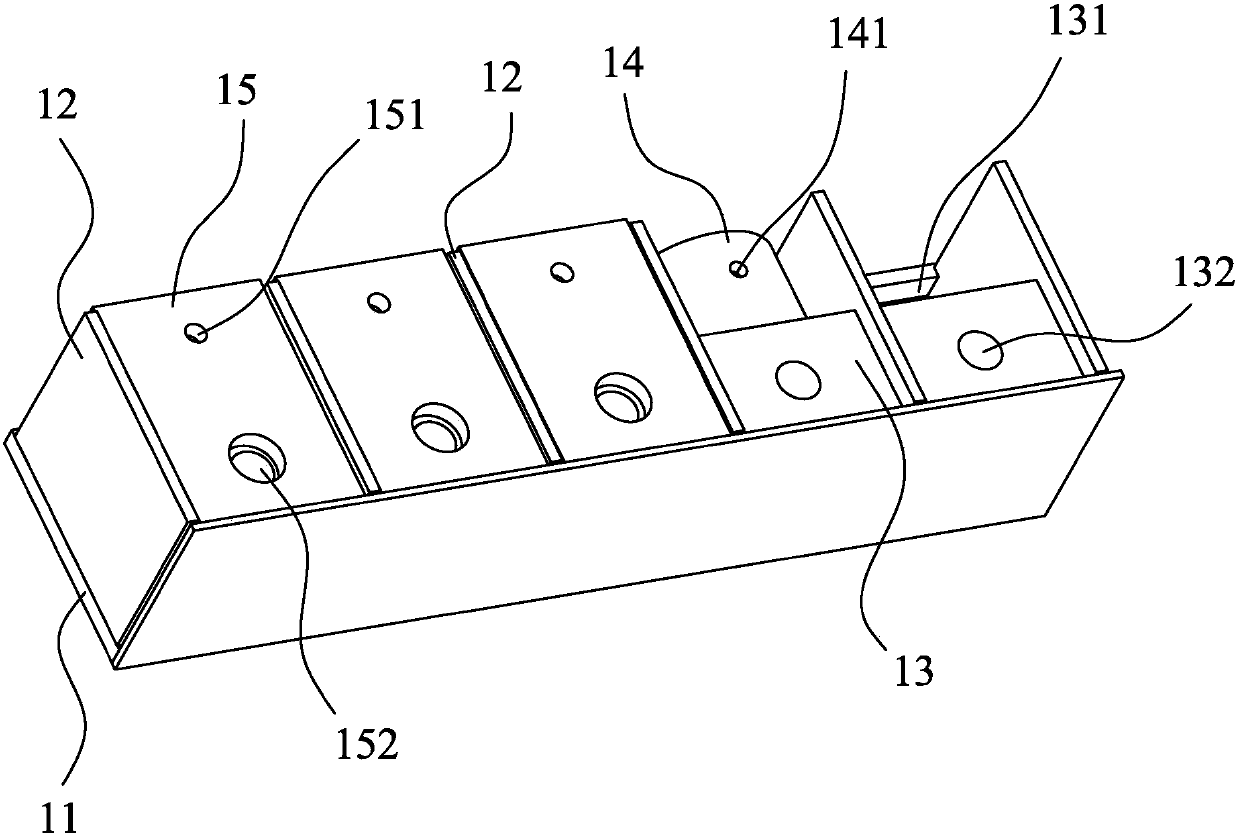

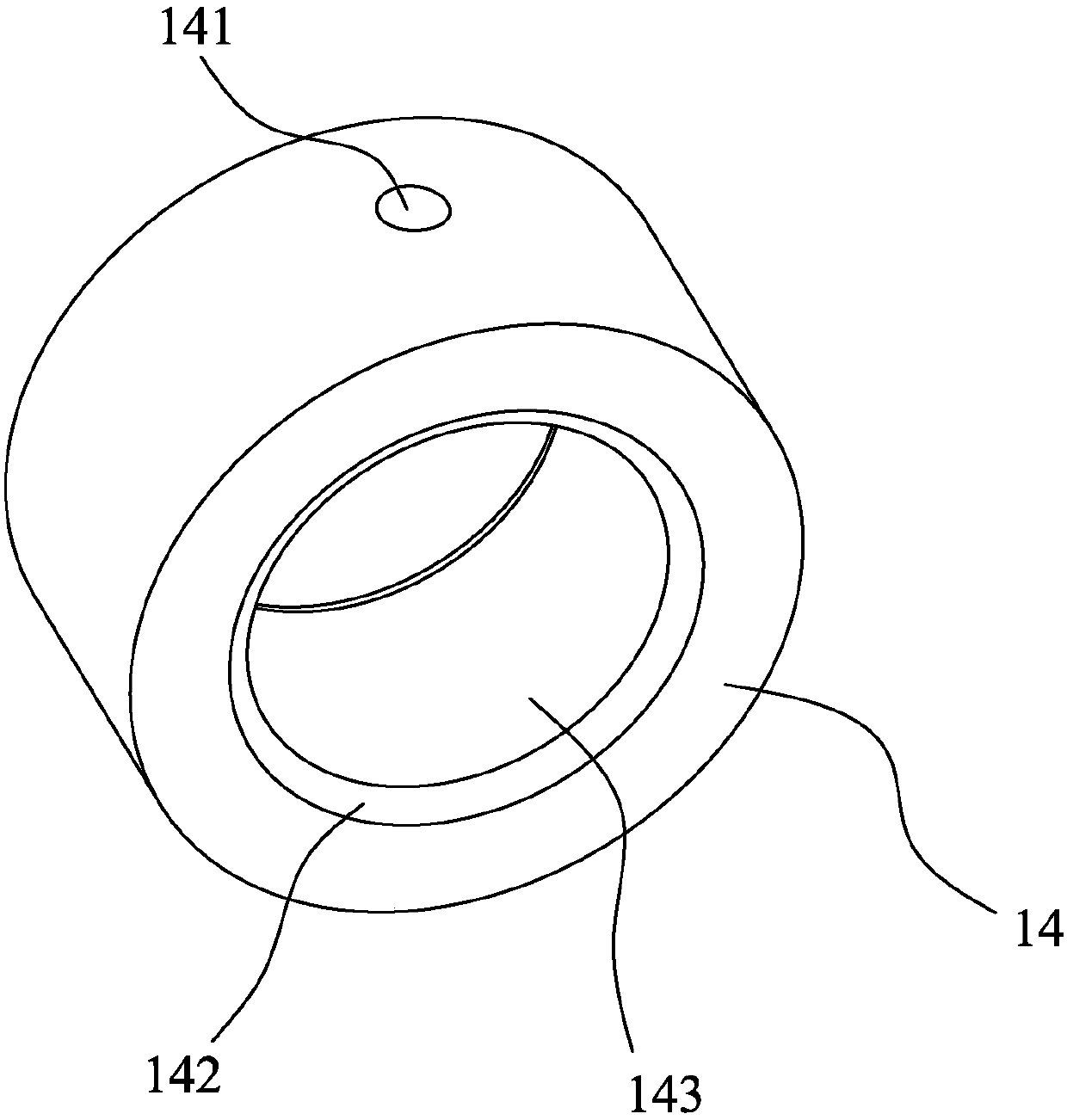

[0037] Such as figure 1 As shown, a lithium battery casing stretch forming machine includes a frame, a mold mechanism 10 arranged on the frame, a shell punching mechanism 20, a shell feeding mechanism 40 for transporting the casing, and a mold mechanism 10 and a punching mechanism. The housing transfer mechanism 30 between the shell mechanisms 20; the mold mechanism 10 includes a mold mounting seat 11, and the mold mounting seat 11 is provided with a plurality of dies 14 arranged side by side in a horizontal direction, and the plurality of dies 14 The openings all face the same side, and the width gradually decreases in turn; the punching mechanism 20 includes a plurality of punches 25 corresponding to the plurality of dies 14, a punch mounting seat 24 for installing the punches 25, a driving punch The rod mounting base 24 moves back and forth toward the opening direction of the die 14 and the first linkage rod 23 connected between the punch mounting base 24 and the first driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com