Vertical roller gap calibrating method

A vertical roll and roll gap technology, which is applied in the field of steel rolling, can solve the problems of operation side and drive side errors, and achieve the effects of avoiding width, accurate calibration, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

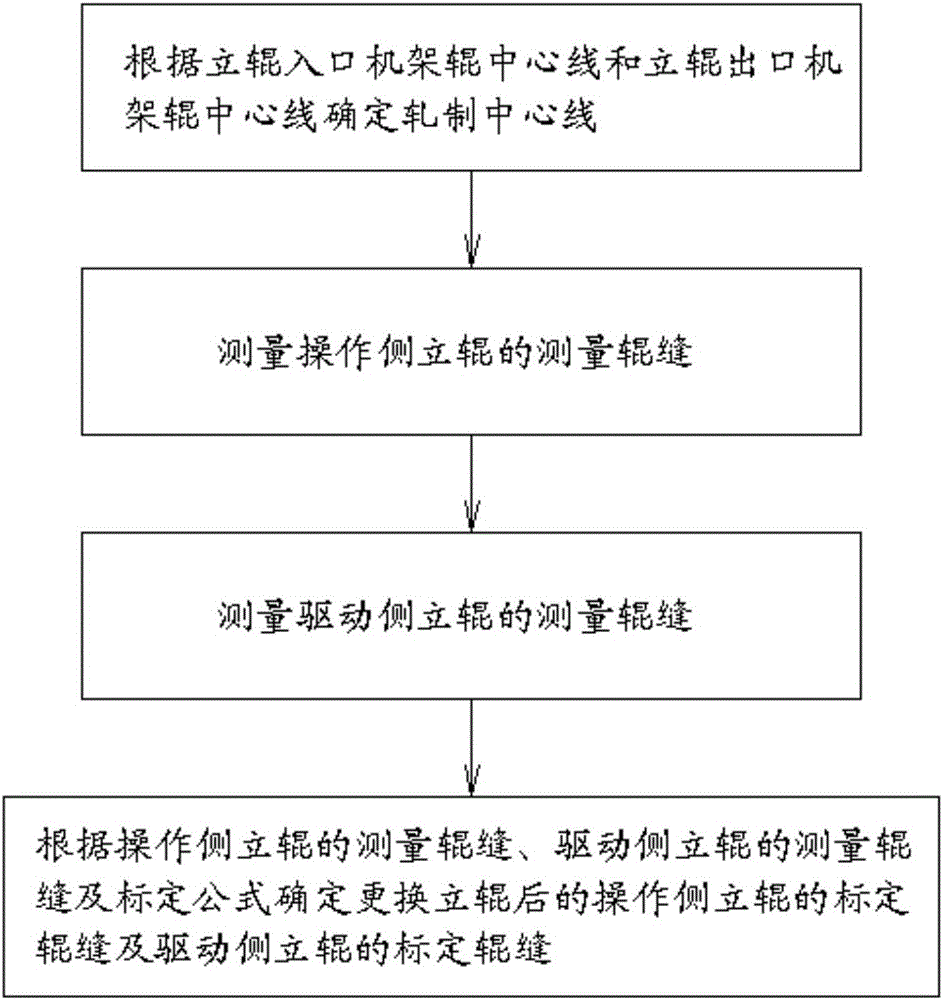

[0045] The embodiment of the present application provides a method for roll gap calibration of vertical rolls, which solves or partially solves the problem that in the prior art, the center line of the lower middle beam is used as the center line of the vertical roll, resulting in a certain difference between the operating side and the driving side during calibration. The technical problem of error, through reasonable selection of the rolling center line and reasonable setting of the calibration formula, the calibration is accurate, the method is simple, the time is saved, the factor of human intervention is reduced, the product quality is obviously improved, and the width and vertical roll area are avoided. resulting technical effects.

[0046] See attached figure 1 , a kind of vertical roller gap calibration method provided by the present invention comprises the following steps:

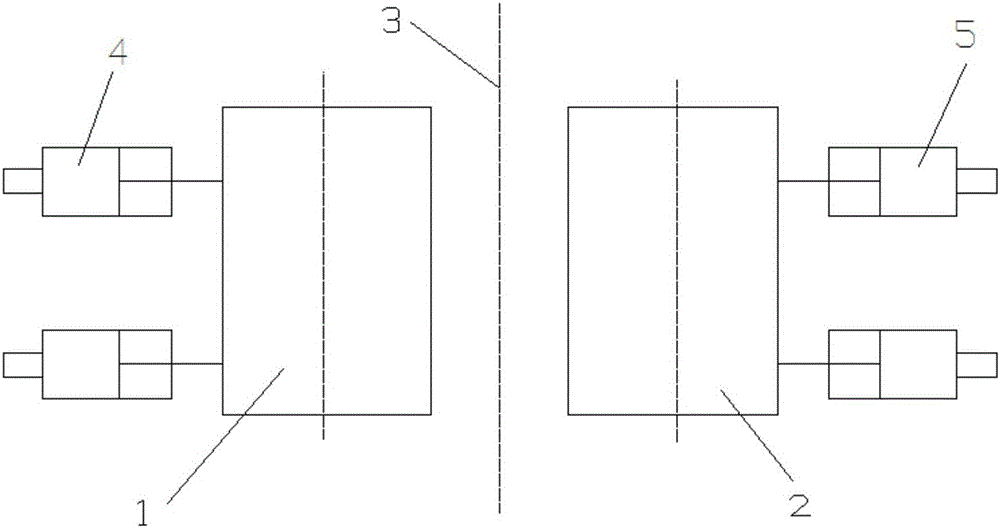

[0047] S1: Determine the rolling center line 3 according to the center line of the vertical ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com