Sweep and dirt removal device for insulators

A technology for cleaning and removing insulators, which is applied in the directions of transportation and packaging, dry gas arrangement, cleaning methods and appliances, etc., can solve the problems of low efficiency of manual implementation, achieve high automation, improve work efficiency, and liberate manpower

Active Publication Date: 2016-10-26

山东孚岳电气有限公司

View PDF7 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] These tasks generally require a lot of labor to complete, which not only requires a lot of expenses, but also puts forward high requirements for people's safety, and the efficiency of manual implementation is low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

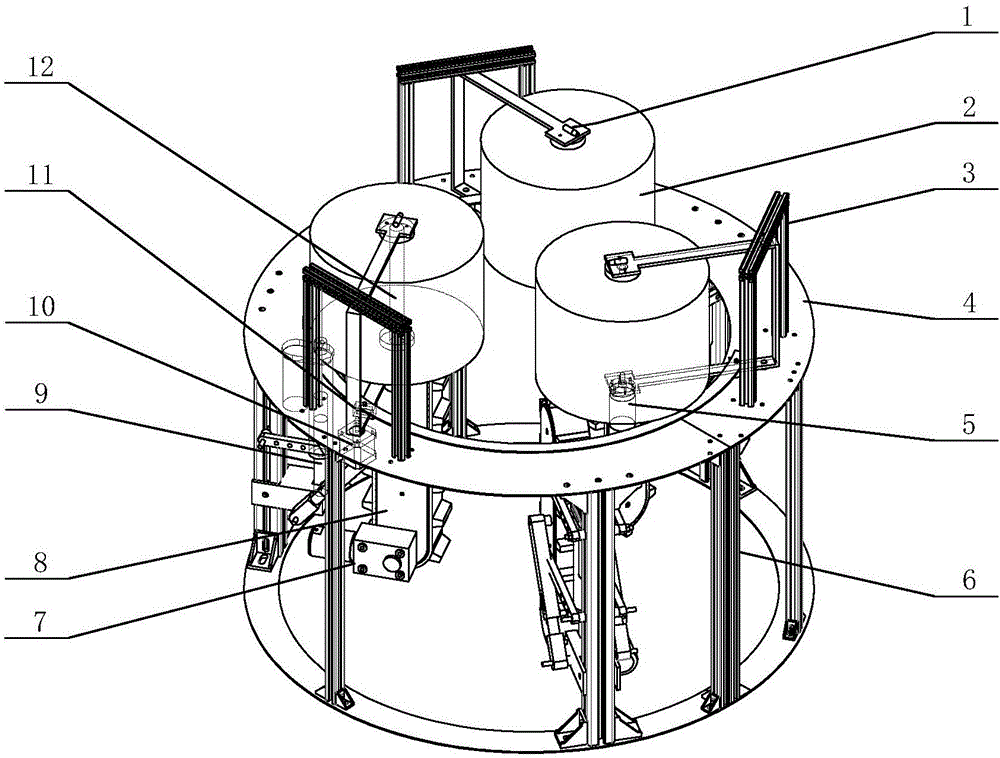

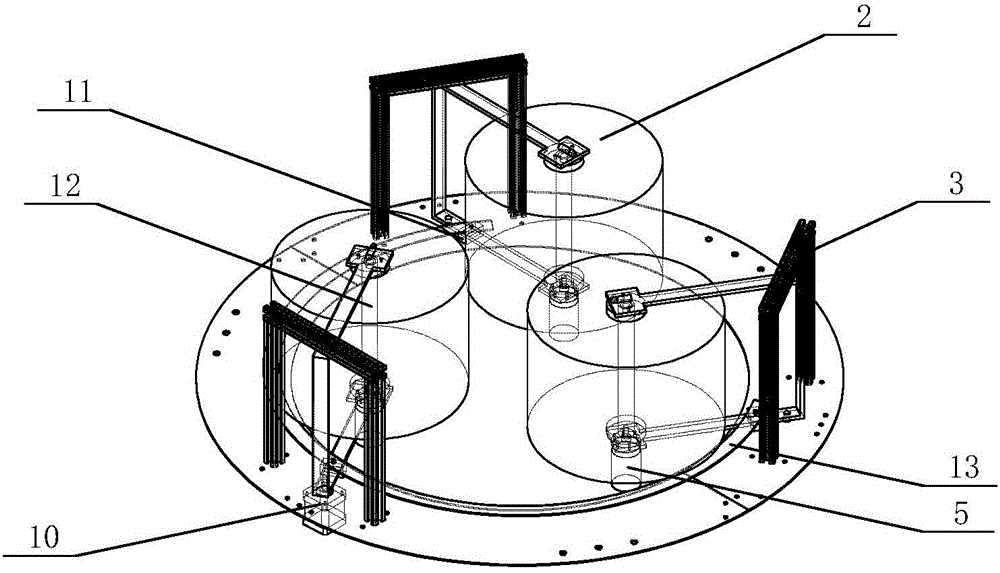

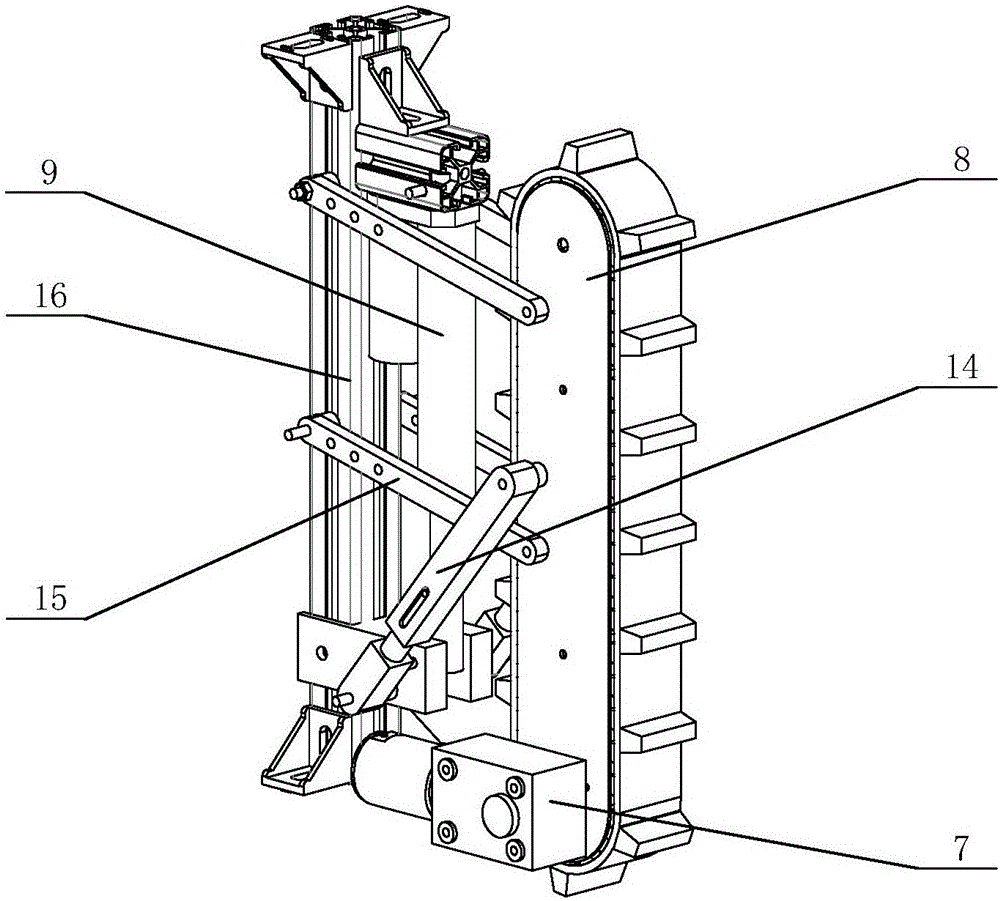

[0027] Such as Figure 1-3 As shown, the insulator cleaning and decontamination device includes a main body frame 6, the upper and lower parts of the main body frame 6 are respectively provided with support plates 4, and also includes:

[0028] The control system includes a central processor and a remote controller for communication connection, and the central processor is equipped with a peripheral drive circuit;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of insulator cleaning, in particular to a sweep and dirt removal device for insulators. The sweep and dirt removal device comprises a main body frame. Each of the upper portion and the lower portion of the main body frame is provided with a supporting plate. The sweep and dirt removal device further comprises a control system, a detection system, a sweep device and a climb device. The sweep and dirt removal device is high in automation degree, can sweep the insulators intelligently and can identify and stride over flanges automatically. In the climb process, the insulator dust removal work is completed safely and efficiently through brushes and high-pressure liquid nozzles which can rotate at a high speed, a remote control can be used for achieving remote control, the identification work of the designated insulators, the enclasping work, the climb work, the dust removal work and the like can be intelligently controlled through the remote control, manpower is saved greatly, and working efficiency is improved on the premise of guaranteeing safety.

Description

technical field [0001] The invention relates to the technical field of insulator cleaning, in particular to an insulator cleaning and decontamination device. Background technique [0002] Because the insulators on the converter station are outdoors for a long time, dust will inevitably accumulate on the porcelain bottle under the action of wind, gravity, and electric field force. When the weather is humid, the soluble substances in the dust dissolve in water to form a conductive water film. There is a leakage current flowing along the surface of the insulator, and when the dirt and humidity are serious, it is easy to cause a flashover accident. [0003] Cleaning and decontamination of the insulators is required for annual maintenance, usually by one of the following methods: [0004] (1) Power off and clean. That is to wipe the pole with a clean cloth after the line is powered off. If it cannot be wiped clean with a cloth, wipe the dirt with a cloth soaked in gasoline or ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B08B1/04B08B3/02B08B13/00B62D55/24F26B21/00

CPCF26B21/00B62D55/24B08B3/02B08B13/00B08B1/12B08B1/32

Inventor 孙亮任崇广

Owner 山东孚岳电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com