Atomization control device and control method

A control device and smoke technology, which is applied to spray devices, liquid spray devices, etc., can solve the problems of large temperature fluctuation range, inability to carry around, and large size of the fog machine, and achieves small temperature fluctuation range, good atomization effect, and controllable Accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

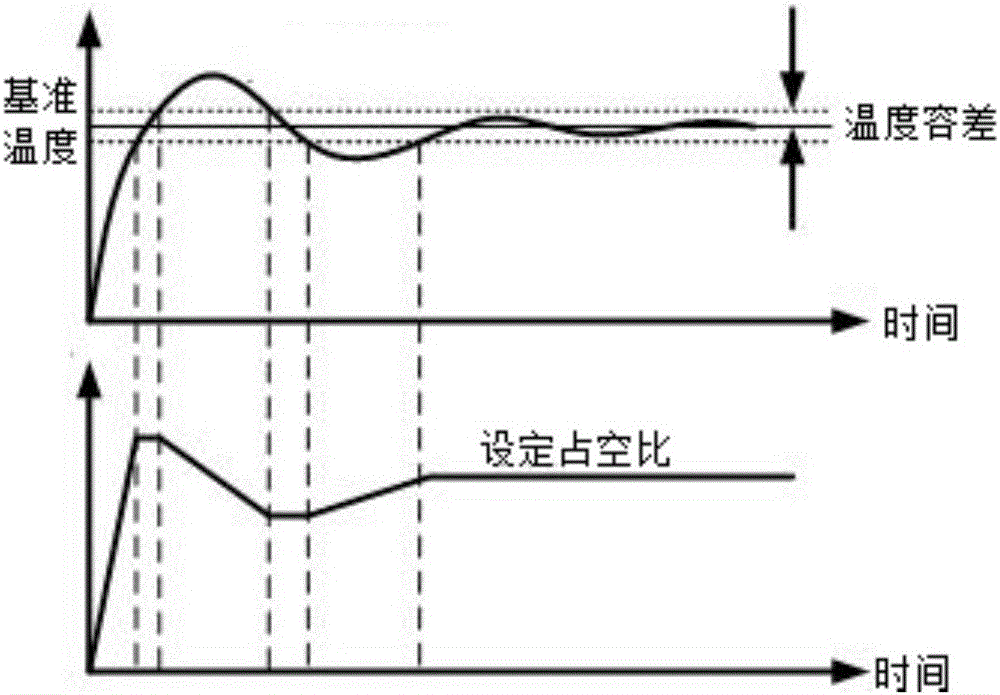

[0050] The smoke adjustment and temperature adjustment process of the PIC single-chip microcomputer are illustrated below in conjunction with the embodiments

[0051] The operating parameters of the PIC single-chip microcomputer are as follows: the proportional parameter of the built-in PID regulator of the PIC chip is P, and the initial value of the integral time of the PID regulator parameter is I. The PIC chip is connected with the display, and the display displays the temperature data collected by the temperature sampling circuit in real time, and the temperature data Real-time display through temperature curve.

[0052] At first, carry out the debugging of proportional parameter P, set the initial value of PID parameter I as infinity, concrete experiment is set to 9999 with I, d=0, P=1, makes PID become a pure proportional algorithm, changes P numerical value this moment, Observing the temperature sampling circuit through the display to collect the collected temperature d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com