Wear-resisting wind guide cone with replaceable lining plate

An air guide cone and lining plate technology, which is applied in the field of mining equipment, can solve the problems of rapid wear of the air guide cone, increased labor intensity of operators, and troublesome replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

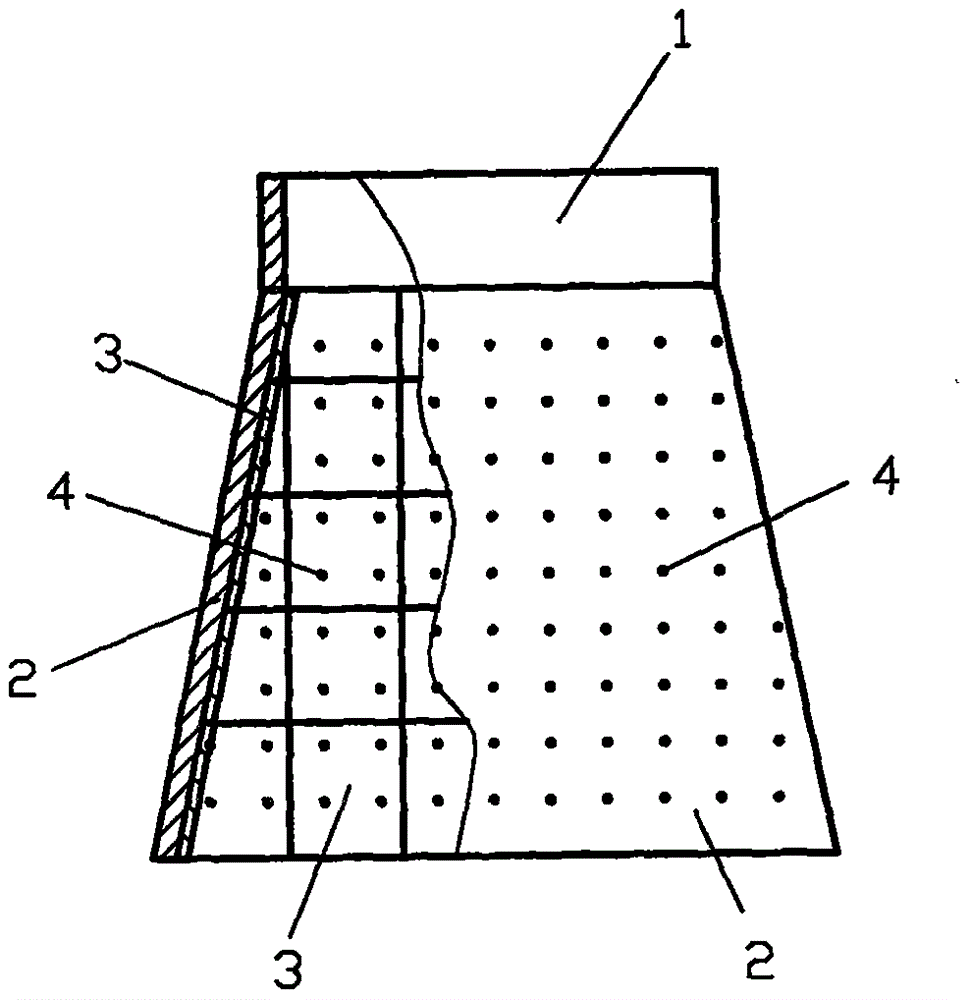

[0007] As shown in the figure, a wear-resistant wind guide cone with a replaceable liner is composed of an upper circular joint 1, a lower cone joint 2, a liner 3, and a bolt hole 4; its feature is that the cylindrical diameter of the upper circular joint 1 is the same The small diameter of the lower conical joint 2 is equal, and one end of the upper circular joint 1 is welded to the small diameter end of the lower conical joint 2; Bolt holes 4 are drilled, and the bolt holes of the lining plate 3 and the bolt holes of the lower cone joint 2 are fastened with bolts behind them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com