A side device for automatically wiping rubber blocks

An automatic wiping and transmission technology, applied in the field of machinery, can solve the problems of heavy physical injury to operators, dependence on manual operation, and easy damage to rubber blocks, etc., to achieve enhanced glue wiping effect, flexible adjustment of contact pressure, and remarkable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

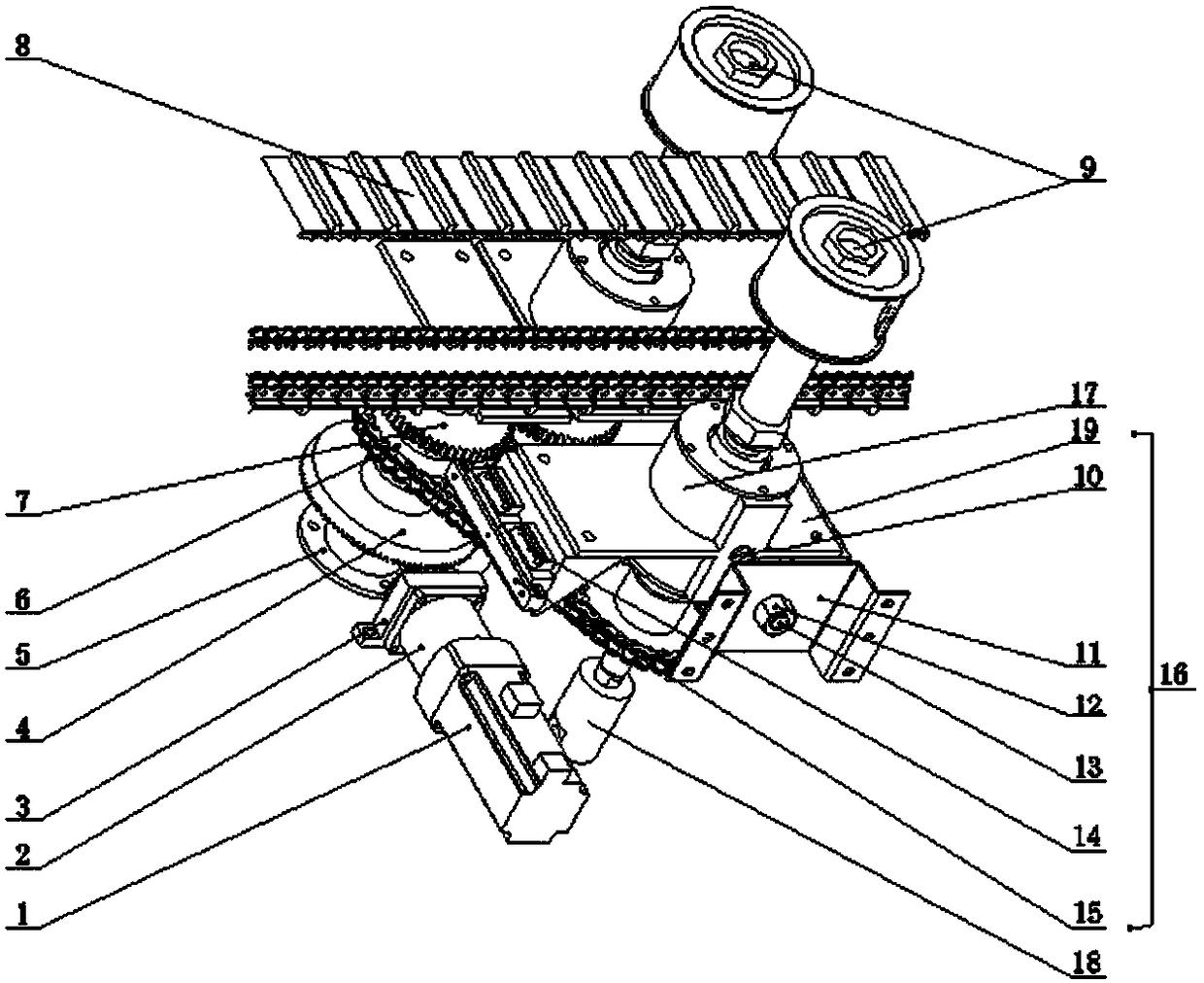

[0025] Embodiment 1 A kind of automatic rubber wiper side device

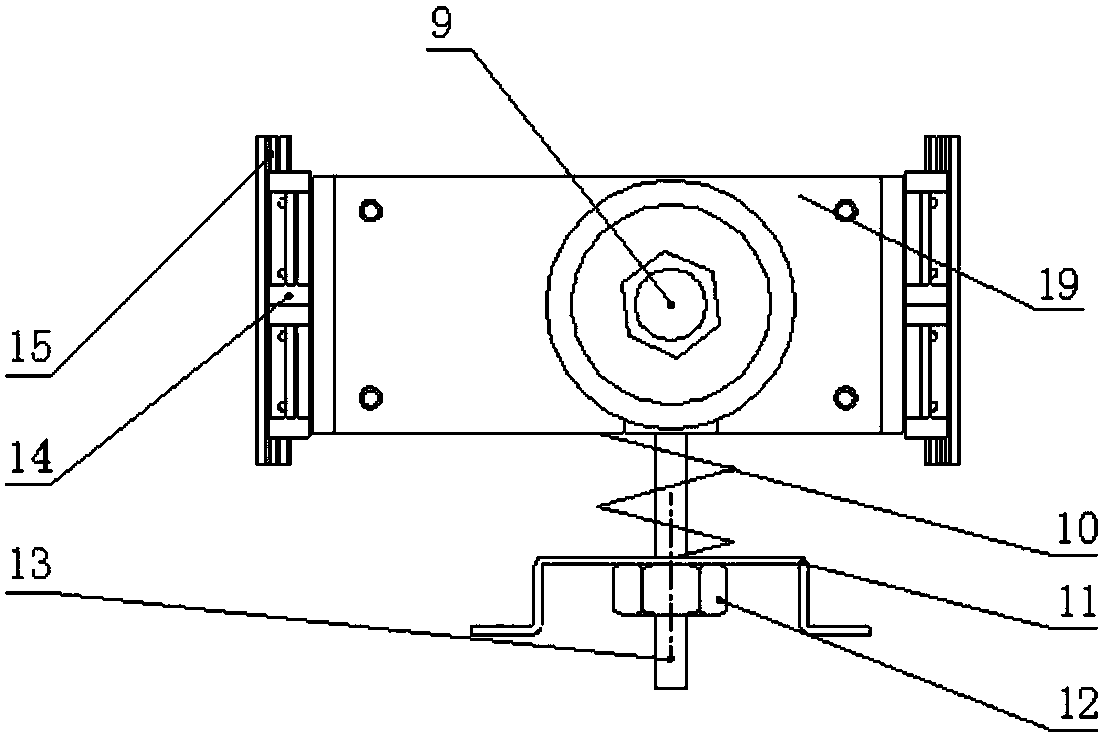

[0026] As shown in the drawings, the present invention includes a servo motor 1, a planetary reducer 2, a motor support frame 3, a bevel gear 4, a sprocket 6, a spur gear 7, a chain 8 on the side of the rubber block, two and vacuum rotating The SUS304 stainless steel rubbing roller 9 connected with the joint 18, the rubber roller pressure automatic adjustment device 16, the transition shaft 5, and the vacuum rotary joint 18 are composed. The rubber rubbing roller pressure automatic adjustment device 16 includes the SUS304 stainless steel slider 14 and the stainless steel slider 14 Adjust stroke guide rail 15, spring limit plate 11, screw rod 13, adjustment nut 12, pressure adjustment floating spring 10. The servo motor 1 is connected with the reducer 2 and fixed on the frame through the motor support frame 3. The output end of the reducer 2 is connected with the driving wheel of the bevel gear 4, and the driven...

Embodiment 2

[0031] An automatic rubber rubbing block side device, comprising a power device, a transmission device, a transmission chain, a rubber rubbing roller 9, and a rubber rubbing roller pressure automatic adjustment device 16, and the rubber rubbing roller 9 is installed on a frame, and the The power unit is connected, the transmission chain is located in the middle of the rubber rubbing roller 9, and the rubber rubbing roller 9 is connected to the automatic pressure adjustment device 16 of the rubber rubbing roller, and the rubber rubbing roller 9 can keep rotating at the same speed. The rubber rubbing roller pressure automatic adjustment device 16 can adjust the contact pressure between the rubber rubbing roller 9 and the rubber block according to the size of the rubber block;

[0032] There are two rubber wiping rollers 9, and the rubber wiping rollers 9 are located on both sides of the transmission chain, and the plane where the two rubber wiping rollers 9 are located is perpend...

Embodiment 3

[0043] An automatic rubber rubbing block side device, comprising a power device, a transmission device, a transmission chain, a rubber rubbing roller 9, and a rubber rubbing roller pressure automatic adjustment device 16, and the rubber rubbing roller 9 is installed on a frame, and the The power unit is connected, the transmission chain is located in the middle of the rubber rubbing roller 9, and the rubber rubbing roller 9 is connected to the automatic pressure adjustment device 16 of the rubber rubbing roller, and the rubber rubbing roller 9 can keep rotating at the same speed. The rubber rubbing roller pressure automatic adjustment device 16 can adjust the contact pressure between the rubber rubbing roller 9 and the rubber block according to the size of the rubber block;

[0044] There are two rubber wiping rollers 9, and the rubber wiping rollers 9 are located on both sides of the transmission chain, and the plane where the two rubber wiping rollers 9 are located is perpend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com