Polarization plate, screen module group and manufacturing method of the screen module group

A polarizing plate and module technology, applied in optics, optical elements, polarizing elements, etc., can solve the problems of unprotected touch sensors, touch sensor damage, TP scrapping, etc., to facilitate visual inspection, reduce production costs, The effect of protection from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

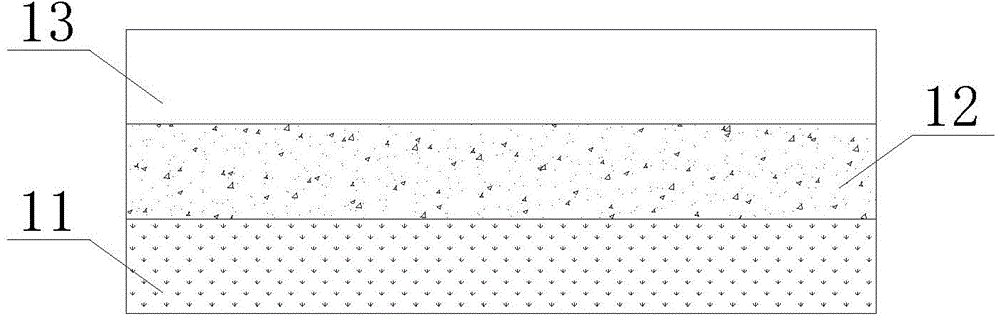

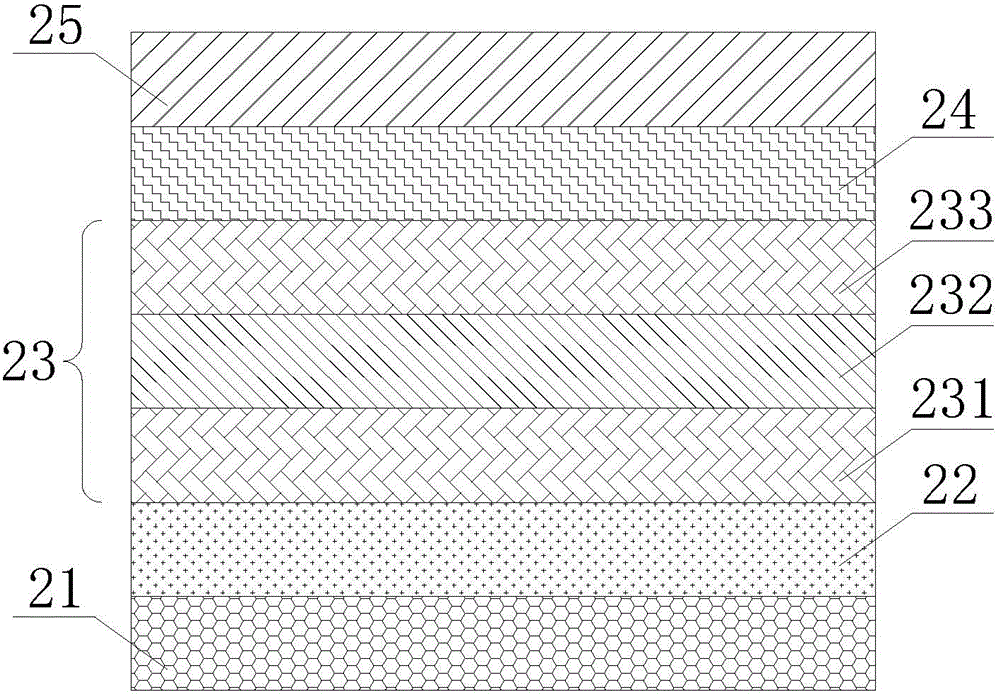

[0059] figure 2 It is a schematic structural diagram of a polarizing plate in the embodiment of the present application; as figure 2 As shown, a polarizing plate includes a release layer 21, a compensating film layer 22, a polarizing film 23, an adhesive layer 24 and a protective film 25; the above-mentioned polarizing film 23 has a light emitting front (ie figure 2 the top surface shown in ) and the back side for light incidence relative to that front side (i.e. figure 2 The lower surface shown), the above-mentioned compensation film layer 22 is covered on the lower surface of the polarizing film, and the release layer 21 is used as a base to cover the lower surface of the compensation film layer 22; meanwhile, the above-mentioned adhesive layer 24 and protective film 25 is stacked on the upper surface of the polarizing film 23 smoothly from bottom to top (that is, the above-mentioned compensation film layer 22, polarizing film 23, adhesive layer 24 and protective film 2...

Embodiment 2

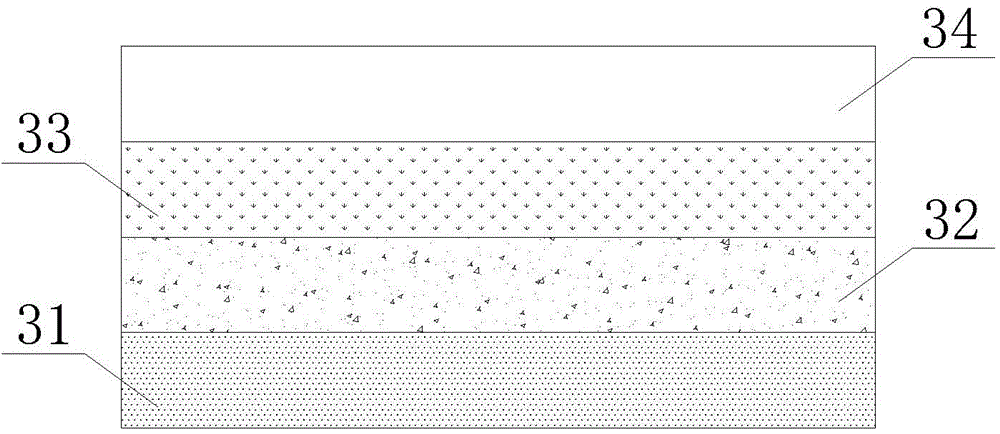

[0063] image 3 It is a schematic structural diagram of the screen module in the embodiment of the present invention; image 3 As shown, the present application also provides a screen module, including a panel (panel) 31, an optical adhesive layer (OCA) 32, a polarizer 33 and a touch panel (TP) 34; the above-mentioned panel 31 has a front surface for light emission , and the optical adhesive layer 32 covers the front surface of the panel 31 , the polarizer 33 covers the upper surface of the optical adhesive layer 32 , and the touch panel 34 is disposed on the upper surface of the polarizer 33 .

[0064] Further, the above-mentioned polarizing plate 33 can be the polarizing plate structure described in the first embodiment above (ie figure 1 ) The structure shown in 2), that is, the polarizer 33 may also include such as figure 1 The structures of the release layer 21, compensation film layer 22, polarizing film 23, adhesive layer 24 and protective film 25 shown in the illustr...

Embodiment 3

[0068] Figure 4 It is a schematic flow chart of a method for preparing a screen module in an embodiment of the present invention; as Figure 4 As shown, a method for preparing a screen module can be applied to prepare the screen module (such as an AMOLED display device, etc.) described in the second embodiment above, such as Figure 2-4 As shown, the method includes:

[0069] First, a panel 31 is provided, and the panel 31 has a front surface for emitting light.

[0070] Secondly, after assembling the IC module and the flexible circuit board FPC (not marked in the figure) on the front surface of the panel 31 , a module test (Module) is performed on the panel 31 .

[0071] Afterwards, the touch panel 34 attached with the polarizer 33 is attached to the panel 31 that has completed the above-mentioned module test and meets the process requirements through the optical adhesive layer 32, so as to form a new screen module.

[0072] Further, by providing a touch panel 34 with a f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com