Terminal structure for superconducting cable and method for manufacturing same

A technology of superconducting cables and structures, which is applied in the direction of cable/conductor manufacturing, usage of superconductor elements, superconducting devices, etc. It can solve the problems of connection resistance deviation, cumbersome, and cumbersome production of normally conductive connecting parts, etc., to reduce The effect of contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

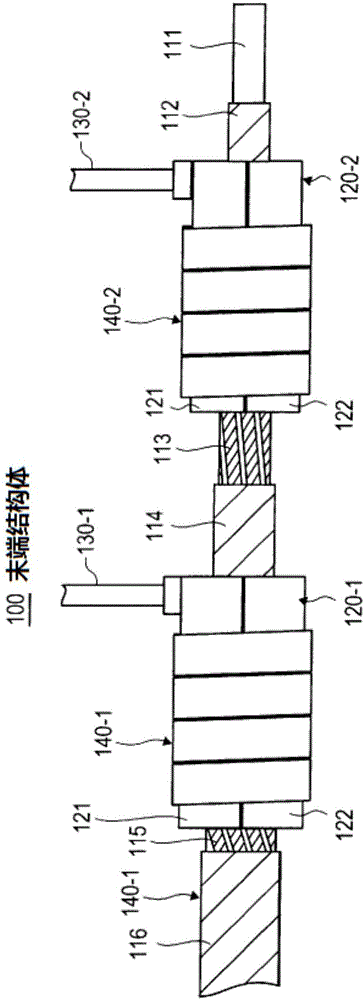

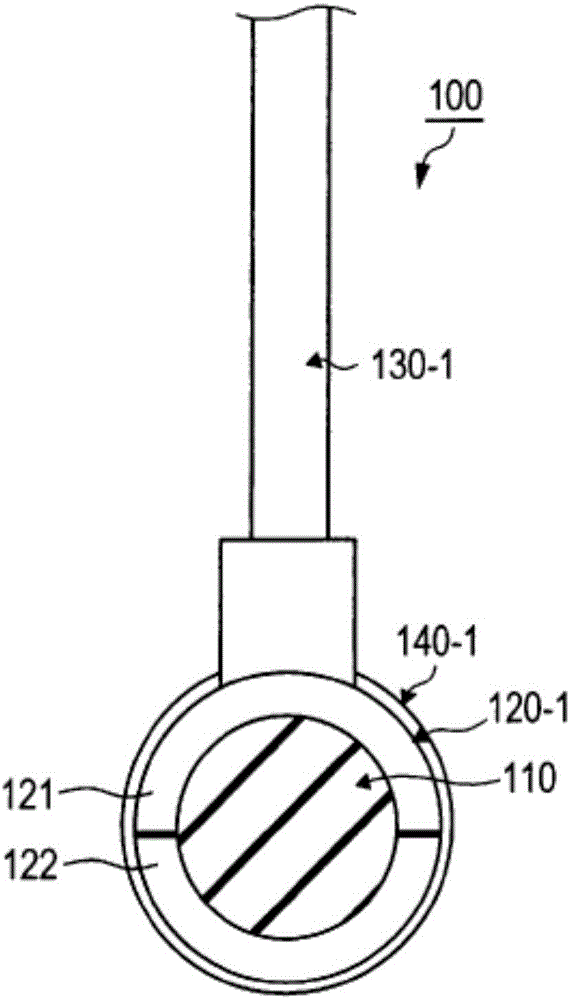

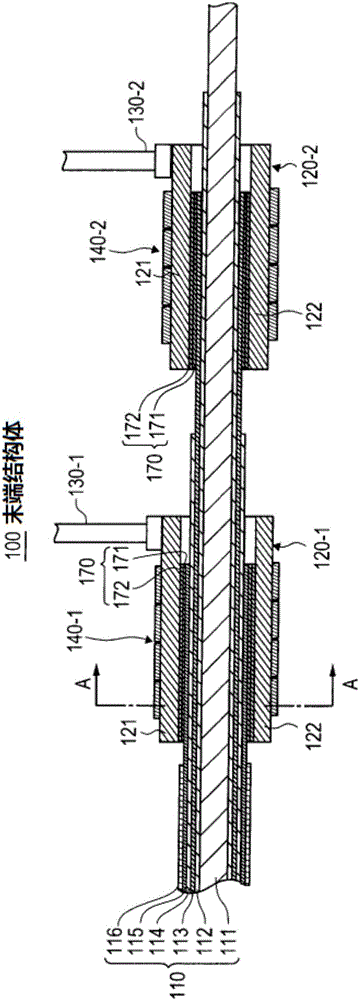

[0117] Formed with thickness 0.12[mm]×width 5[mm] Figure 5 REBa shown y Cu 3 o z It is a superconducting wire, and 10 superconducting wires are wound around the core material to form each layer of a superconducting tape to form a superconducting cable. Using the superconducting cable, cylindrical electrodes, and diameter-reducing parts, the above-mentioned structure is produced. End structure 100 . The inner surface of the cylindrical electrode 120 - 1 and the outer peripheral surface (surface on the substrate side) of the superconducting tape 115 are connected by solder 170 . In addition, when the tubular electrode 120 is connected to the superconducting strip 115, pre-solder portions 171 and 172 are provided on the connection surfaces of the two, such as Figure 9 ~ Figure 14 They were fabricated as shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com