Modular structural system

A technology of structural elements, elements, applied in the field of modular structural systems, which can solve the problems of weakening the structure, discontinuity, unable to provide suitable resistance to shear, traction, bending, compression and torsional stress, etc., to achieve the effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

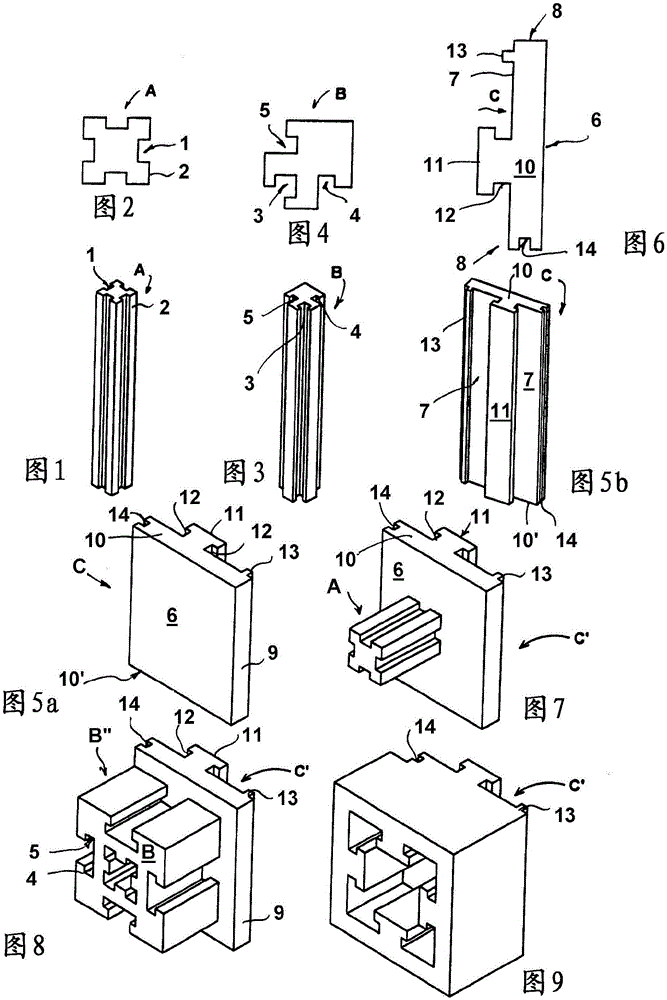

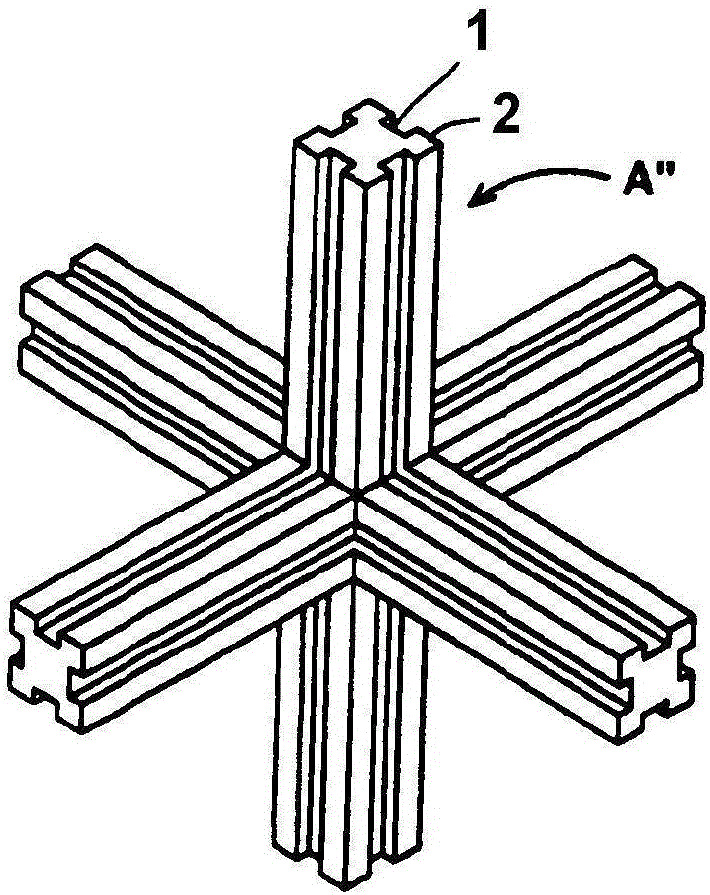

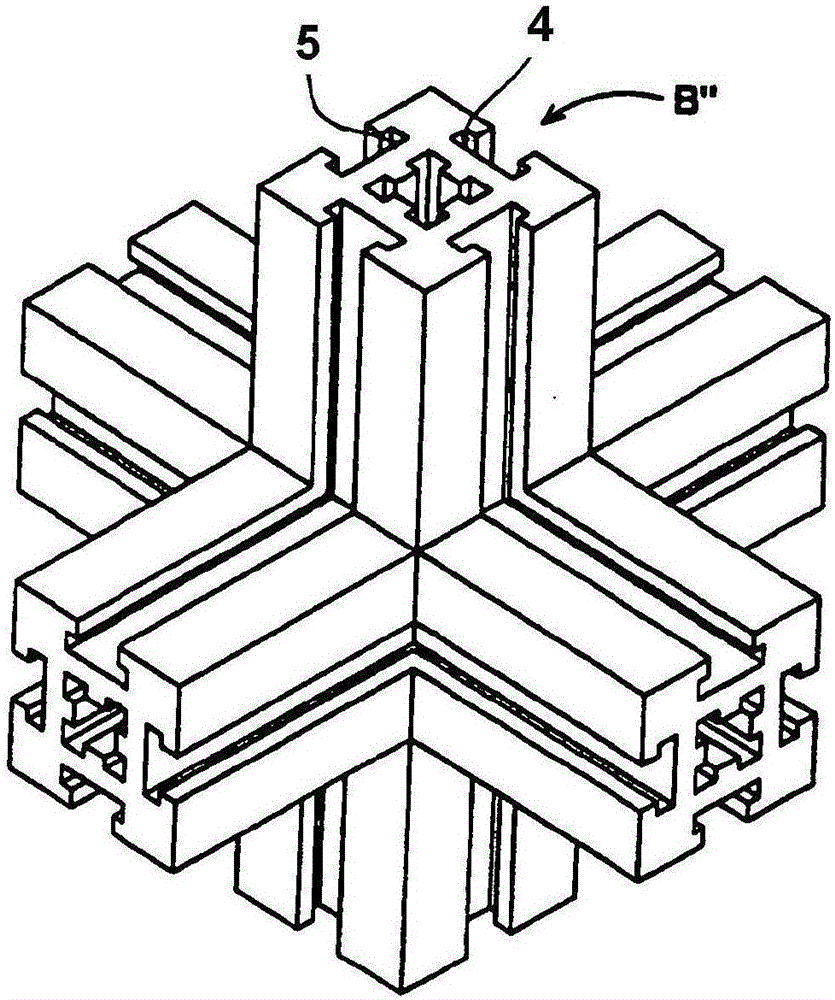

[0083] The figures show preferred embodiments of the structural system according to the invention obtained by combining elements A, B, C, D, node elements C' and nodes A", B", C", which are The sum node allows interconnection with four other structural systems positioned vertically relative to the first system, to obtain a structural assembly according to the invention.

[0084] For details, refer to the attached Figures 1 to 6 , these figures show a preferred embodiment of the elements A, B and C constituting the modular construction system according to the invention.

[0085] exist figure 1 Axonometric view of and in figure 2 Element A, shown in cross-section of , has a roughly square cross-section (specifically as figure 2 shown in ) or rectangular section (as in Figure 25b and 26c ) shown. In said element A, sliding grooves or longitudinal rails 1 are formed and distributed symmetrically on the four sides of the section. exist figure 1 and 2 as well as Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com