Tyre quality managing and controlling system

A quality control system and tire technology, applied in manufacturing computing systems, measuring devices, electromagnetic measuring devices, etc., can solve the problems of time-consuming and laborious, unable to guarantee data accuracy and long-term storage, affecting quality analysis, etc., to reduce work intensity, It is convenient for query and analysis to realize the effect of full detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

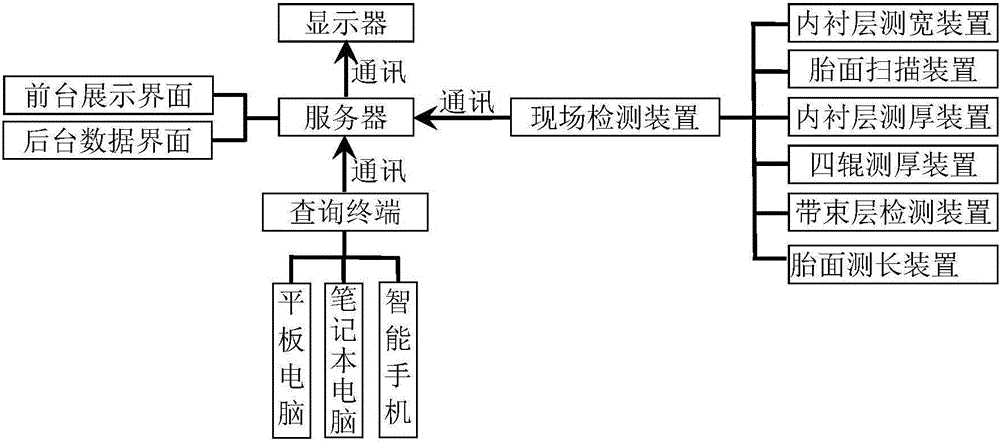

[0021] Such as figure 1 A tire quality control system is shown, the system includes a server, a display, an on-site detection device, an inquiry terminal and a communication device; the server is connected to the display, the on-site inspection device and the inquiry terminal through the communication device.

[0022] The server is divided into a foreground display interface and a background data interface.

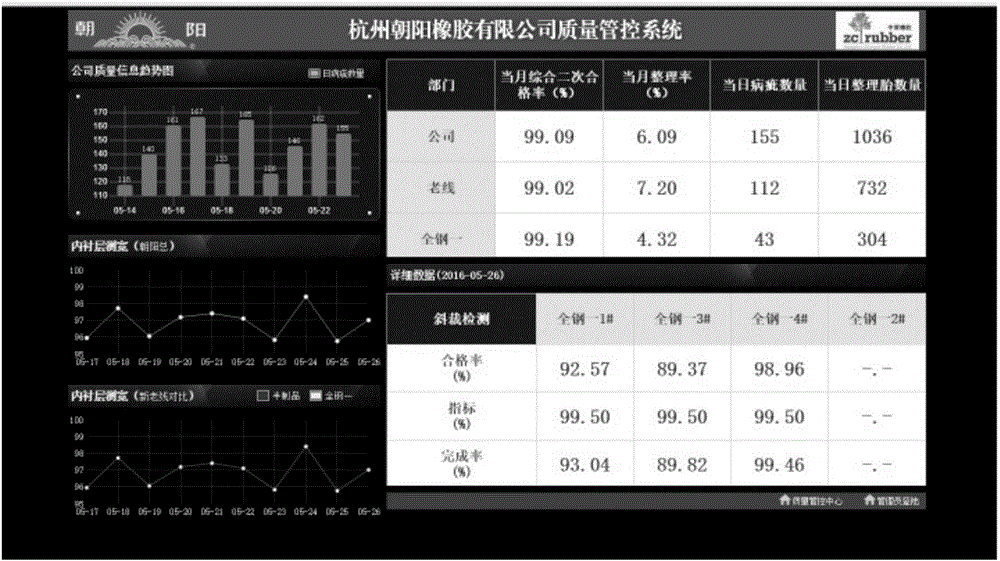

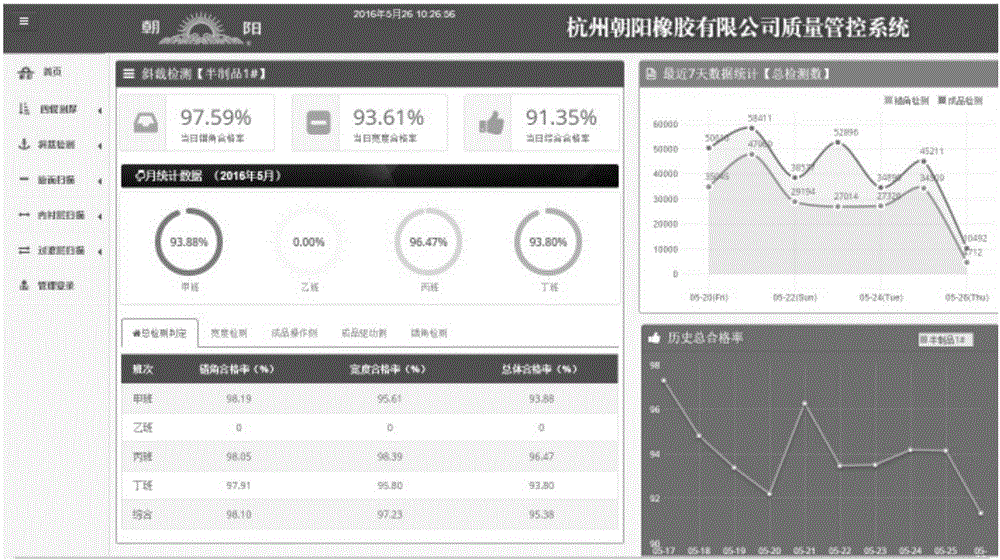

[0023] Front display interface, such as figure 2 As shown, it mainly displays the company's quality trend chart, and scrolls to display the daily pass rate of each testing equipment on site, the recent change trend of pass rate, and the comparison of the pass rate of the same machine. Among them, if the daily pass rate of each testing equipment on site is lower than the index value, an alarm will be issued to remind the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com