A method for testing the dynamic heat transfer process of building walls

A technology of dynamic heat transfer and process testing, applied in the direction of material thermal development, etc., can solve the problems of inability to detect the thermal performance of the wall, limited testing conditions, and steady-state heat transfer process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

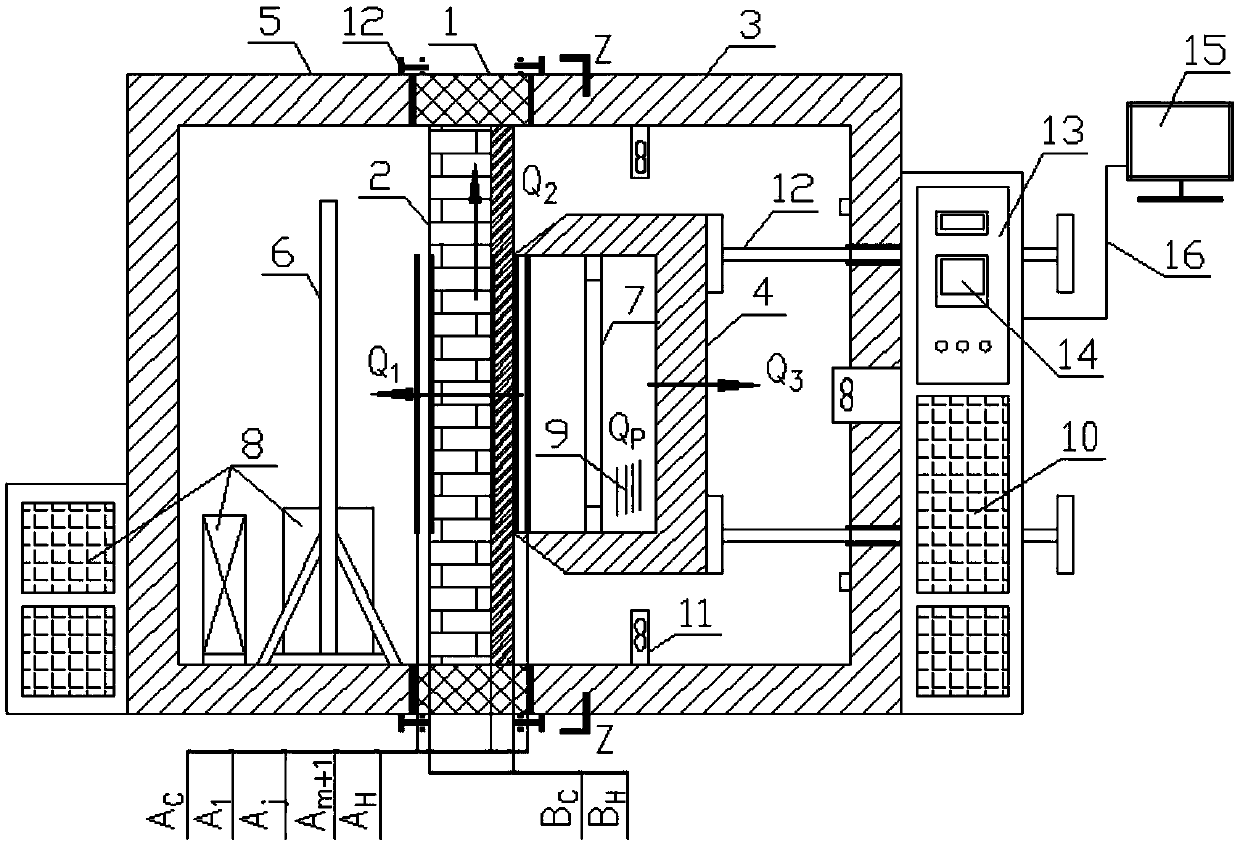

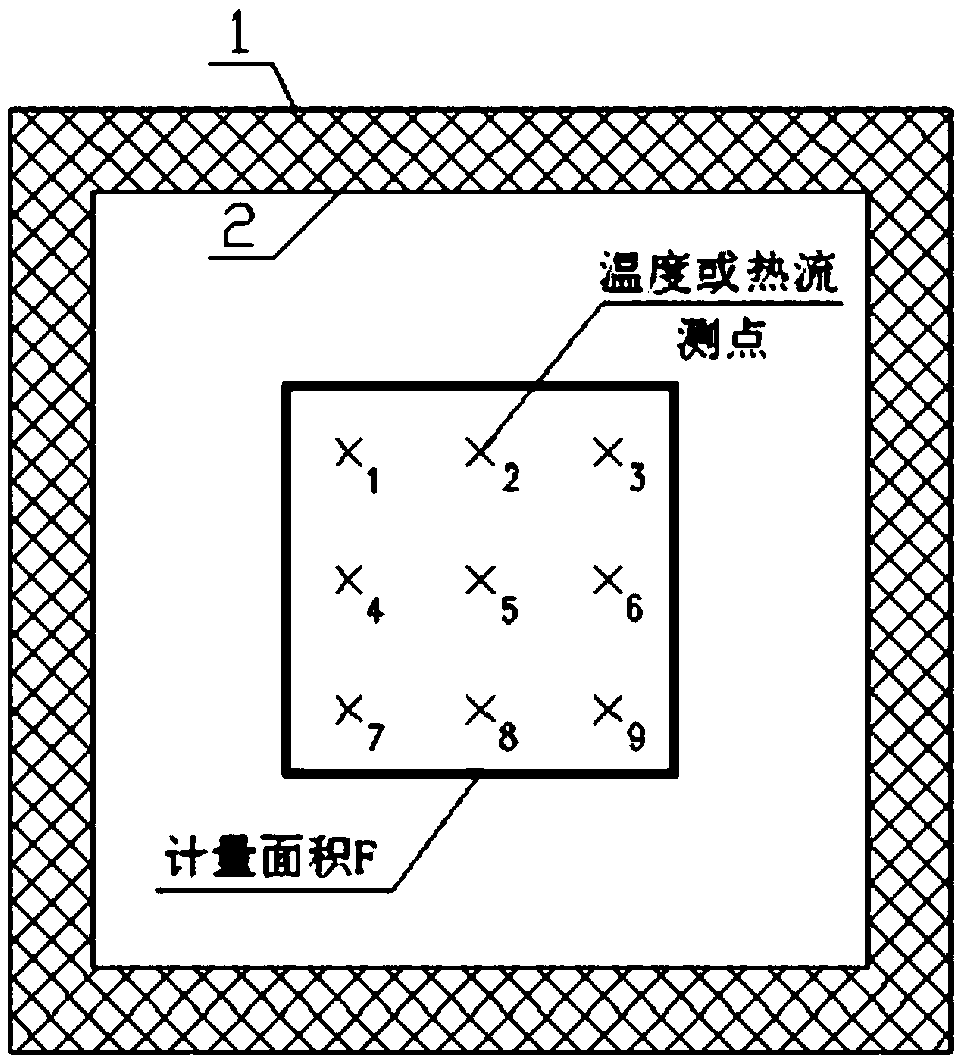

[0072] This embodiment discloses a test method for the steady-state heat transfer process of a building wall, and the specific test process is as follows:

[0073] 1 Preparation before the test. The wall test piece 2 is made on site, and it is fixed between the hot and cold boxes by using the clamping device 12 to conduct the wall heat transfer test. The user inputs the temperature constant value T of the cold box 5 in the computer client 15 c , metering hot box 4 and protective hot box 3 temperature constant value T h [and T h -T c ≥20℃], as a steady state heat transfer test condition.

[0074] 2) Heat transfer process test. After the user inputs the test working condition, the working condition data is imported to the temperature control intelligent instrument monitoring system 13 through the data transmission line 16, which controls the environmental conditions in the hot and cold boxes on both sides of the wall specimen 2. During the steady-state heat transfer test, ...

Embodiment 2

[0080] This embodiment discloses a test method for the dynamic heat transfer process of a building wall, and the specific test process is as follows:

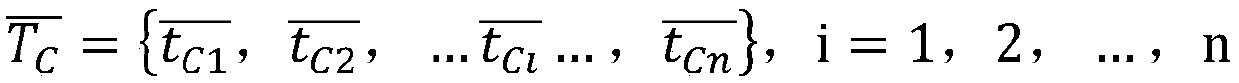

[0081] 1) Preparation before the test. The wall test piece 2 is made on site, and it is fixed between the hot and cold boxes by using the clamping device 12 to conduct the wall heat transfer test. The user inputs the temperature dynamic setting data set of the cold box 5 in the computer client 15 Metering hot box 4 and protective hot box 3 temperature dynamic setting data set Set the time interval of working condition change as Δτ, and the test time as τ, so the test process is divided into n=τ / Δτ time periods on average. data set and The expression of is as follows:

[0082]

[0083]

[0084] In the formula, is the average temperature of the air in the cold box at the time point iΔτ; is the average temperature of the metering hot box and the protective hot box at the time point iΔτ.

[0085] 2) Heat transfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com