Adaptive reflective infrared laser industrial hazardous gas leakage monitoring device

An infrared laser and leaking gas technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of high false alarm rate, difficulty in installation and debugging of the optical path of the device, poor stability and reliability of measurement results, etc., to improve detection sensitivity , Guaranteed real-time tracking and aiming, easy to install and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

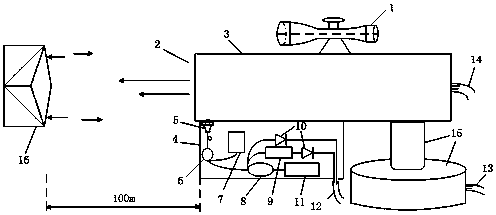

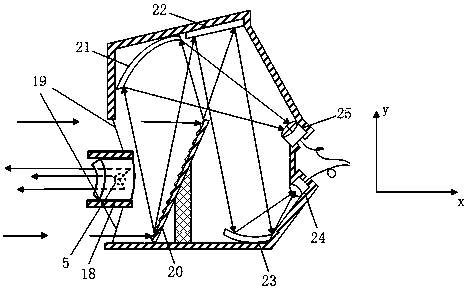

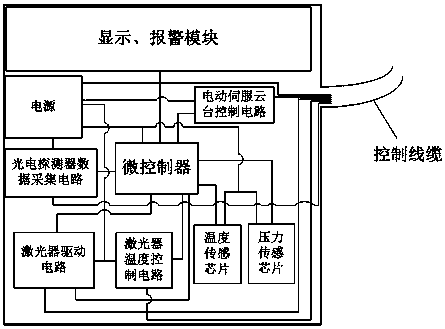

[0030] like Figure 1 to Figure 3 As shown in the figure, an adaptive reflective infrared laser industrial hazardous leakage gas monitoring device includes: a visual sight 1, a casing 2, a laser red beam and a laser infrared detection beam arranged in the casing 2 to send and receive in one Probe, electric servo pan / tilt 15 and control box. The probe is installed and fixed on the electric servo pan / tilt 15 . The probe and the control wire in the control cable of the electric servo pan / tilt 15 are connected with the corresponding circuit module assembly in the control box. The electric servo pan / tilt 15 adopts the worm gear transmission mode, is driven by a two-axis servo motor, and has two degrees of freedom in the horizontal and vertical directions. By controlling the servo motor in the electric servo head 15, the horizontal rotation and the pitch rotation of the electric servo head 15 can be realized, so as to realize the azimuth adjustment of the casing 2 fixed thereon. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com