Quantitative concrete workability testing device and method

A testing device, concrete technology, applied in the direction of measuring devices, flow characteristics, instruments, etc., can solve the problems of quantitative characterization and workability of testing methods, and achieve the effect of rapid and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

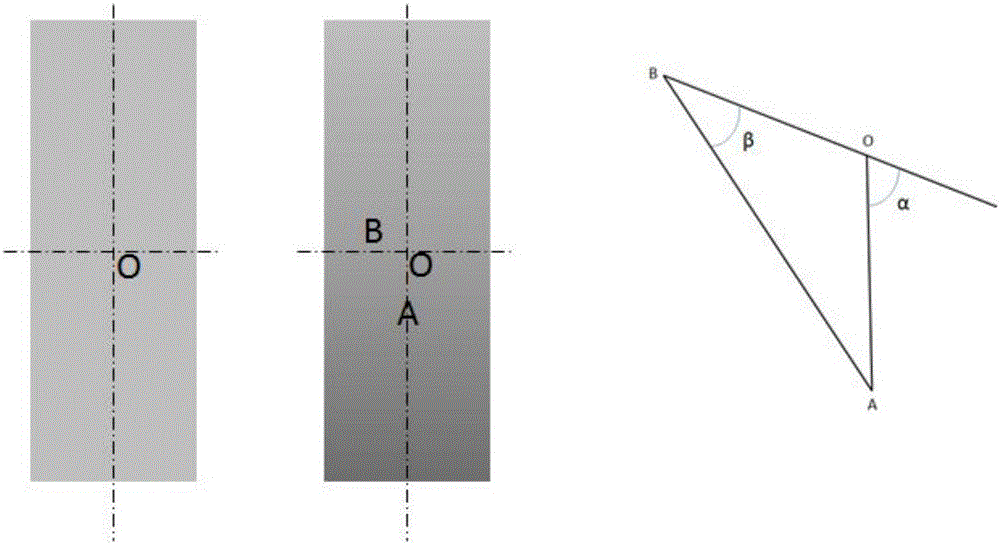

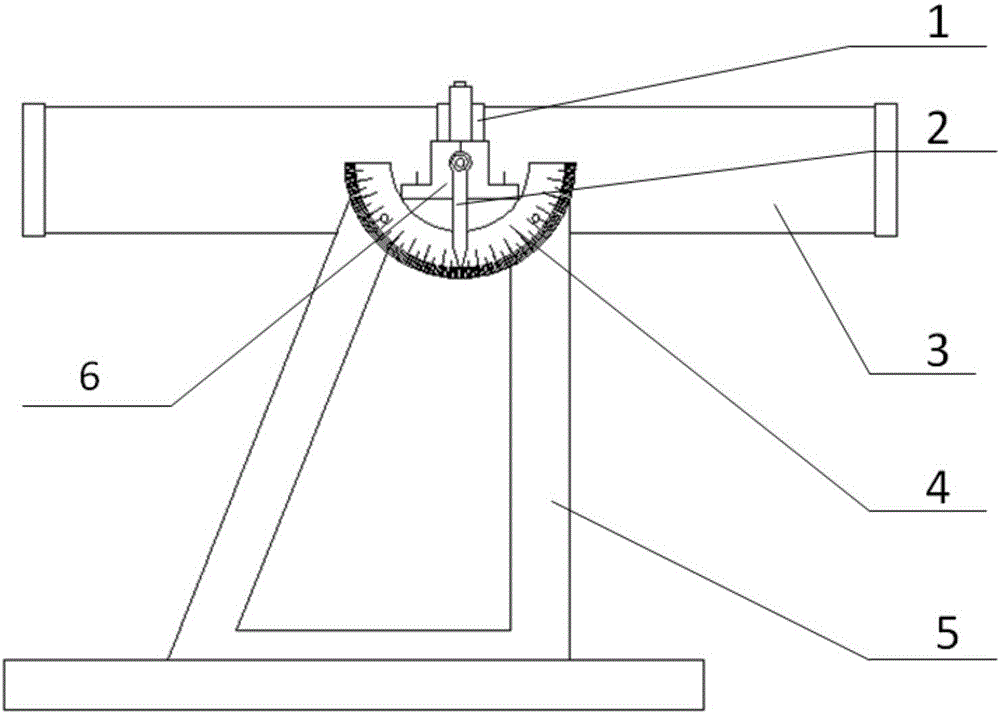

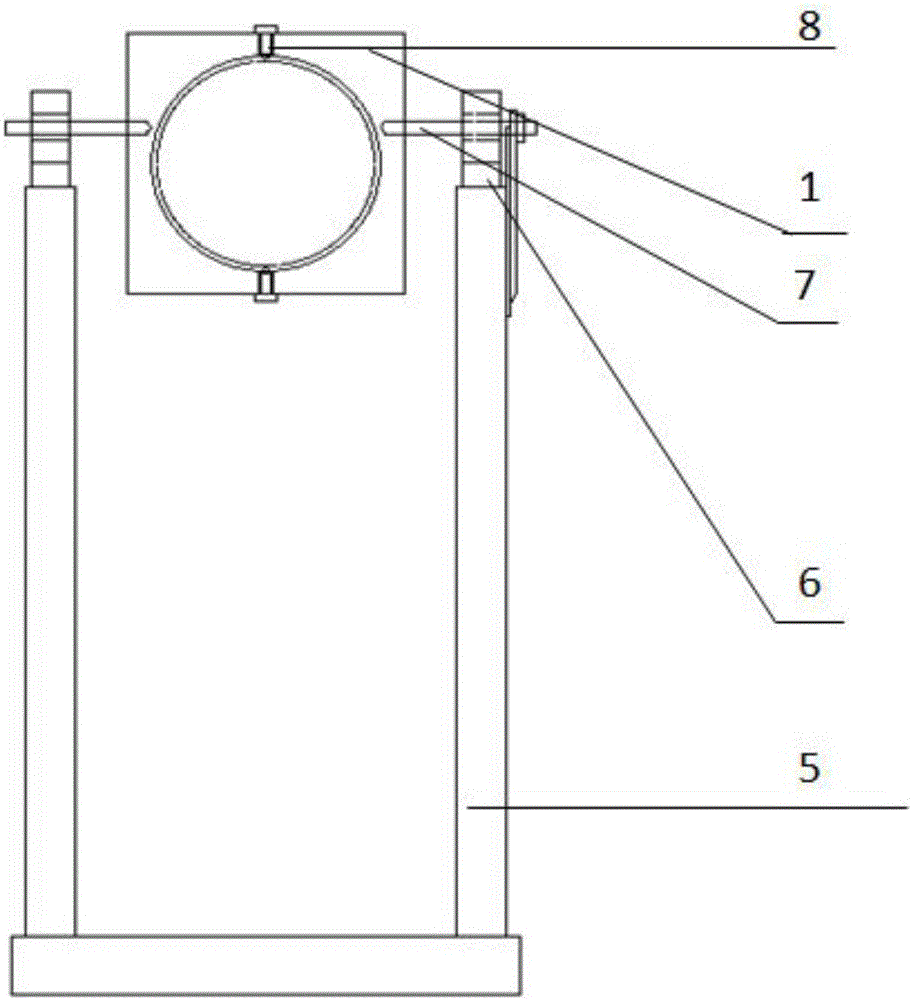

Method used

Image

Examples

Embodiment 1

[0032] Using Onoda PII52.5 cement, ISO standard sand, commercially available polycarboxylate superplasticizer The solid content is 20%, and the mortar is prepared according to the ratio shown in the table below, and the fluidity and workability are tested. In addition, hydroxypropyl methyl cellulose ether (HPMC) is used as a workability adjustment commonly used in the field of concrete technology The agent is applied in the mortar to adjust the workability of the mortar. Table 1 lists the fluidity and workability description of the corresponding proportion mortar.

[0033] Table 1 mortar ratio

[0034]

[0035]A mold with an inner diameter of 48 mm and a length of 350 mm is used for the workability test. The distance between the eccentric axis of the chuck and the horizontal axis is 6 mm, and the chuck is fixed at the center of the mold. The test steps are as follows:

[0036] (1) Put the empty mold into the chuck and make it vertical, loosen the mold to make it rotate ...

Embodiment 2

[0045] Use Onoda PII52.5 cement, 5-25mm continuous graded limestone gravel, medium sand with a fineness modulus of 2.6, first-class fly ash that meets the national standard, S95 finely ground slag powder, commercially available polycarboxylate Acid superplasticizer (solid content 20%), prepare ordinary C30 concrete pumping concrete. Pumping concrete with different workability was prepared by changing the amount of admixture and using workability modifier hydroxypropyl methylcellulose ether (HPMC). Concrete mix ratio and fresh performance are shown in the table below:

[0046] Table 3 Concrete mix ratio (kg)

[0047] cement

[0048] Table 4 Properties of Fresh Concrete

[0049]

[0050]

[0051] A mold with an inner diameter of 95mm and a length of 695mm is used for the concrete workability test. The distance between the eccentric axis of the chuck and the horizontal axis is 23mm, and the fixed position of the chuck is 10mm from the center of the mold. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com