Soil mass dry-wet circulating annular shearing instrument capable of measuring humidity

A dry-wet cycle and soil technology, used in instruments, measuring devices, scientific instruments, etc., can solve the problems of difficult determination of soil deformation properties and difficulty in simulating the dry-wet cycle changes of soil, so as to reduce damage and ensure deformation and displacement. effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

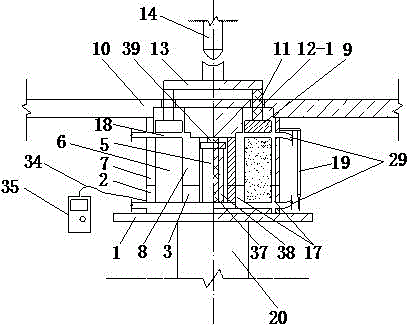

[0033] This embodiment provides a soil dry-wet cycle ring shear instrument with measurable humidity. Device 33, the top of the vertical loading device is provided with a dial gauge 28;

[0034] The workbench includes a horizontally arranged working plane 23 and supports 24 arranged at both ends of the working plane 23, and the center of the working plane 23 is provided with a through hole b 12-2;

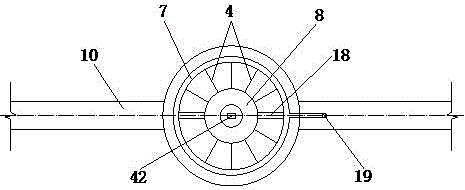

[0035] Such as figure 1 As shown, the main shear box includes a top plate 10, a chassis 1 of the same size and shape that is located directly below the top plate 10, and cross bars that are located at both ends of the top plate 10. The center of the chassis 1 is provided with a chassis rotating shaft 5. The disc 10 is rotationally connected with the chassis 1 through the chassis rotating shaft 5, the top disc 10 lower surface is fixed with a top disc inner guard ring 8 and a top disc inner guard ring 8, and the upper surface of the chassis 1 is provided with a chassis inner guard r...

Embodiment 2

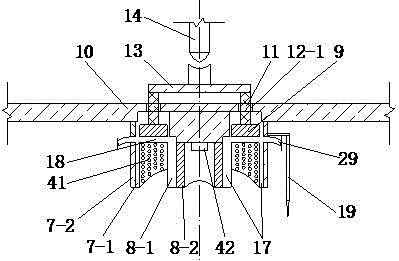

[0047] On the basis of embodiment 1, this embodiment provides a kind of Figure 6 The shown humidity-measurable soil dry-wet cycle ring shear instrument, the vertical loading device is a reaction frame; as image 3 As shown, the top of the chassis rotating shaft 5 is provided with a fixed connecting buckle 39 , and the lower end surface of the top plate 10 is provided with a connecting groove 42 matching the fixed connecting buckle 39 .

[0048] Among them, such as Figure 7 As shown, the reaction force frame 21 includes an upper cross bar 21-1, a lower cross bar 21-2 and two vertical bars 22 connecting the two ends of the upper cross bar 21-1 and the lower cross bar 21-2. The lower crossbars are respectively located on the upper and lower sides of the working plane 23, and the two ends of the working plane 23 are also symmetrically provided with through holes c 12-3, and the vertical bar 22 passes through the working plane 23 through the through holes c 12-3;

[0049] The c...

Embodiment 3

[0054] On the basis of Embodiment 2, this embodiment provides a soil dry-wet cycle ring shear instrument with measurable humidity, the hygrometer probe 4 is in the shape of a flat terminal, and 1 / 3 of the hygrometer probe 4 is inlaid Inside the chassis 1 or the annular pressure plate 9, the other 2 / 3 of the raised parts are exposed outside. The chassis rotating shaft 5 includes a rotating shaft center shaft 37 and a rotating shaft sleeve 38 .

[0055] The hygrometer probe 4 is arranged parallel to the chassis 1, and the raised part is embedded in the annular sample 6 during the test (because the part of the probe embedded in the annular sample 6 is very small compared to the volume of the annular sample 6, it can be ignored. impact on the test results), these protrusions can measure the humidity of the soil ring sample 6 on the one hand, and can play the role of fixing the ring sample 6 when rotating and shearing; the top plate 10 remains fixed during the test. Move, and chas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com