U-type ground heat exchanger heat and moisture transfer performance simulation test device and test method

A buried tube heat exchanger and simulation test technology, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of inability to obtain U-shaped buried tube heat exchange performance, and achieve simple structure and work clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

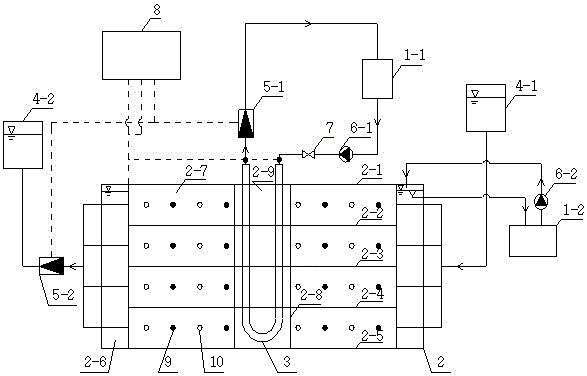

[0026] The present invention will be further described below in conjunction with accompanying drawing:

[0027] Such as figure 1 As shown, a U-shaped buried tube heat exchanger heat and humidity transfer performance simulation test device, the test device consists of the first constant temperature water area 1-1, the second constant temperature water area 1-2, the first circulating water pump 6-1, the second Circulating water pump 6-2, sand mold test bench 2, U-shaped buried pipe heat exchanger 3, constant temperature remote boundary simulation system, groundwater seepage simulation system, first flow meter 5-1, second flow meter 5-2, flow adjustment A valve 7, a temperature sensor 9, a humidity sensor 10 and a data acquisition device 8 are connected;

[0028] The sand mold test bench 2 consists of a top plate 2-1, a first middle partition 2-2, a second middle partition 2-3, a third middle partition 2-4, a bottom plate 2-5, a constant temperature water jacket 2-6, a backfill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com