Automobile hub bearing testing machine

A technology of bearing test and automobile wheel hub, applied in the direction of mechanical bearing test, etc., can solve the problems of inaccurate test results, unreasonable structure design, inaccurate loading simulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

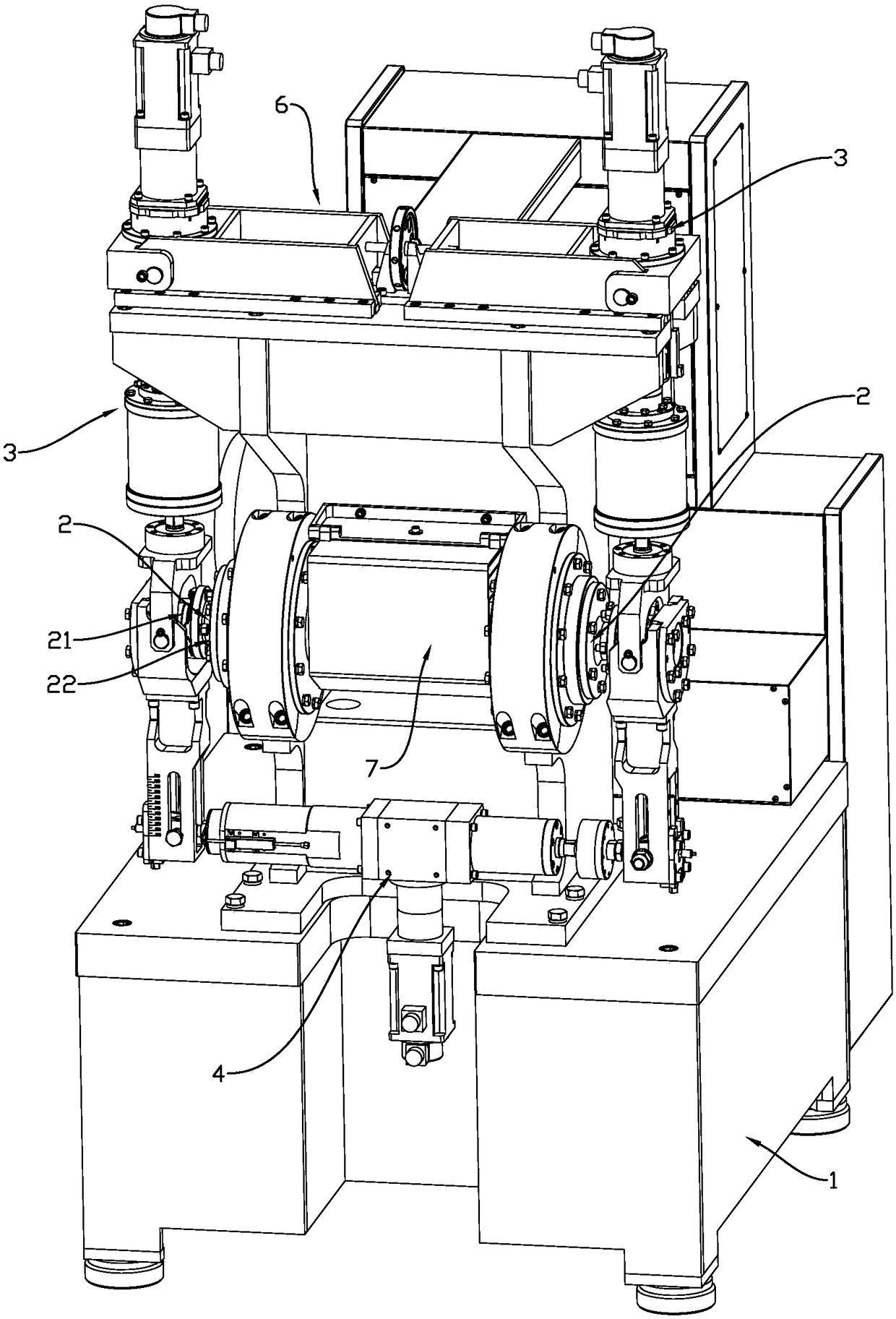

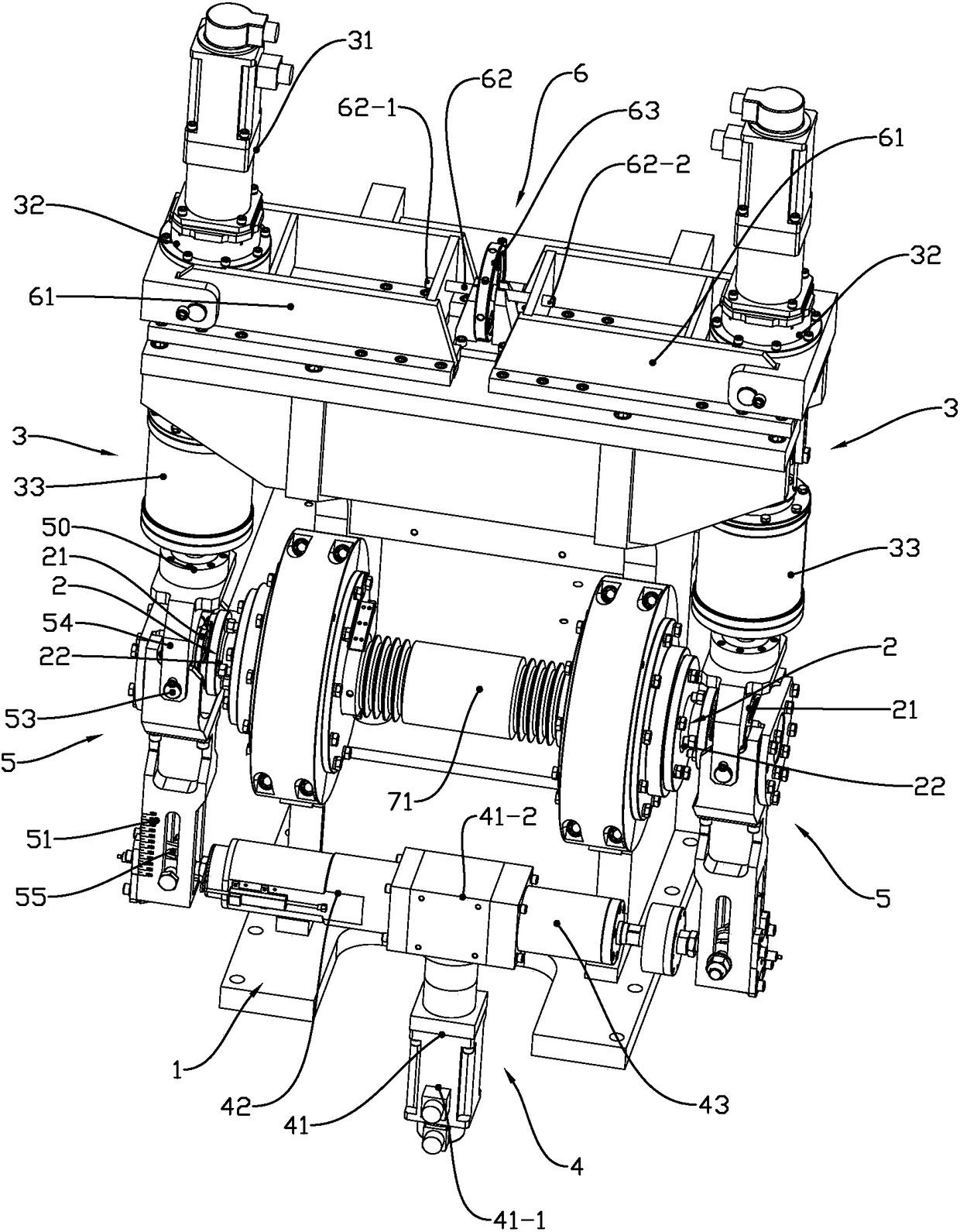

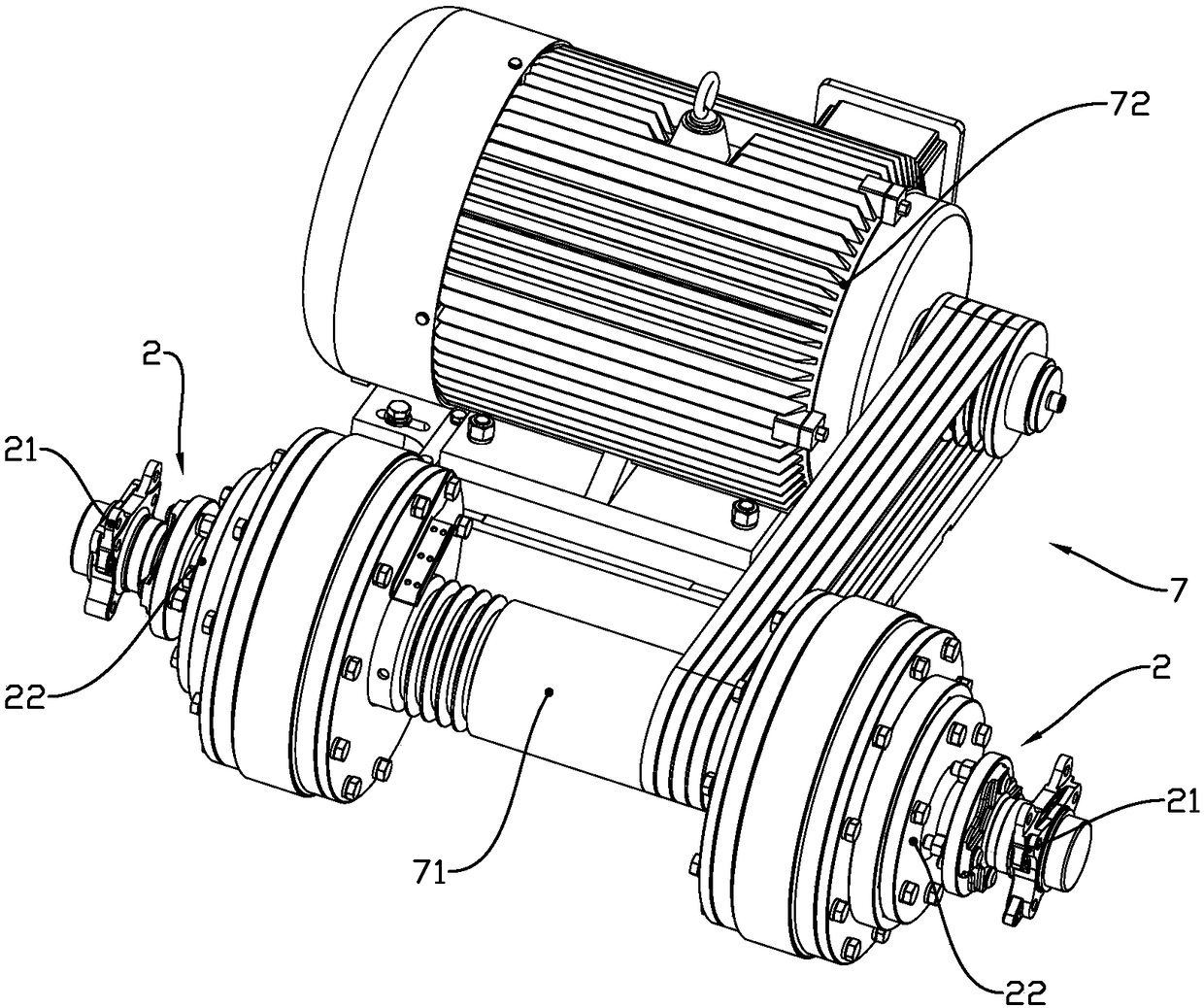

[0038] Such as Figure 1~12 As shown, a kind of automobile hub bearing testing machine disclosed by the present invention includes a body 1, an electric control system, a main shaft device 7, a test shaft device 2, an axial loading device 4 and a radial loading device 3, and a test shaft device 2 Including the hub bearing 21 used for the test, the inner ring of the hub bearing 21 is rigidly connected to the main shaft 71 of the main shaft device 7. Connected, the main shaft device 7 includes a main shaft 71 and a rotary driver 72 that drives the main shaft to rotate. The rotary driver 72 usually adopts a motor, and the motor is driven through a transmission belt. The main shaft device 7 and the electronic control system are conventional technologies in the art, so no further details The main shaft 71 of the main shaft device 7 is arranged horizontally, and the test shaft device 2 is rigidly connected to both ends of the main shaft 71 of the main shaft device 7 in the axial dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com