electric heater

An electric heater and heat sink technology, applied in the field of electric heaters, can solve the problems of circuit insulation damage, heating plate extension deformation damage, connector damage, etc., and achieve the effect of saving ground area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

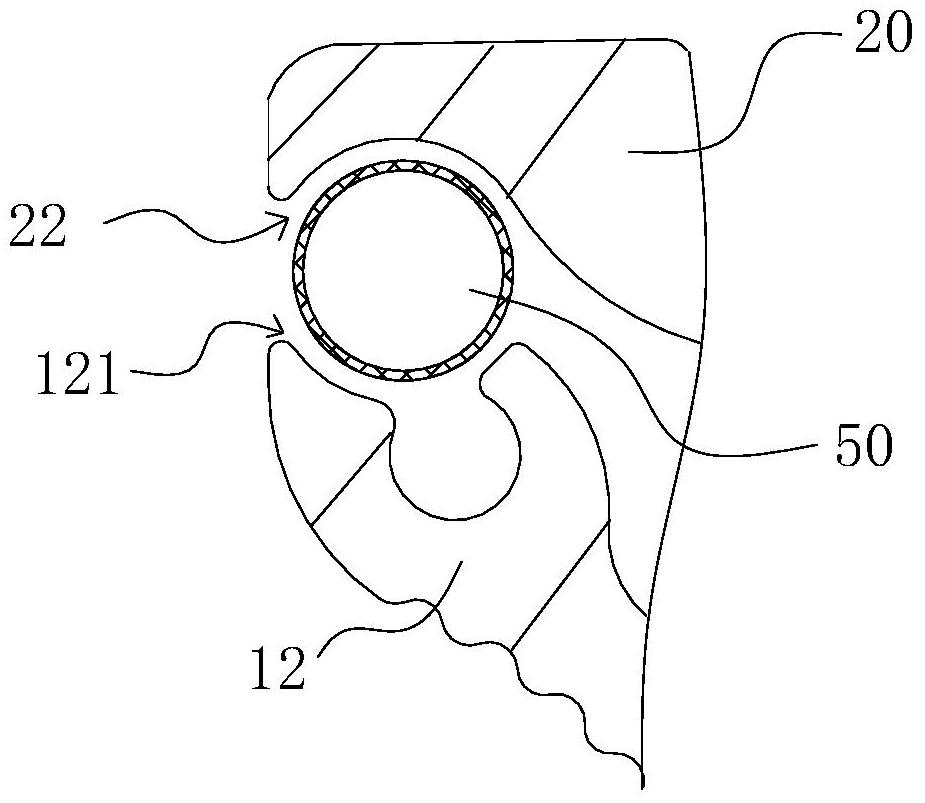

[0009] Combine below figure 1 , 2 , 3, the present invention is described in further detail.

[0010] Such as figure 1 As shown, an electric heater includes a base plate 10 connected to the wall, a heat dissipation plate 20 is covered on the base plate 10, and a heating element 30 is attached to the heat dissipation plate 20. The heat dissipation plate 20 and the base plate 10 Forms a floating connection that extends along the surface of the board. The function of the floating connection is to ensure that the cooling plate 20 can freely extend along the surface of the plate without being damaged when it is heated.

[0011] Such as figure 1 As shown, the base plate 10 is surrounded by the base plate 11 and the side wall 12 to form a box shape, and the outer surface of the base plate 11 is provided with a closed T-shaped groove 111, and the bolt heads of the bolts connected to the wall are placed in the T-shaped groove 111. The bolts in the T-shaped slots can easily fix the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com