Membrane type vibration absorber with frequency adjustable

A vibration absorber and diaphragm type technology, which is applied in the field of vibration absorbers, can solve problems such as narrow space for equipment feet, inability to arrange vibration absorbers, and no installation space, etc., and achieve good environmental adaptability, height reduction, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

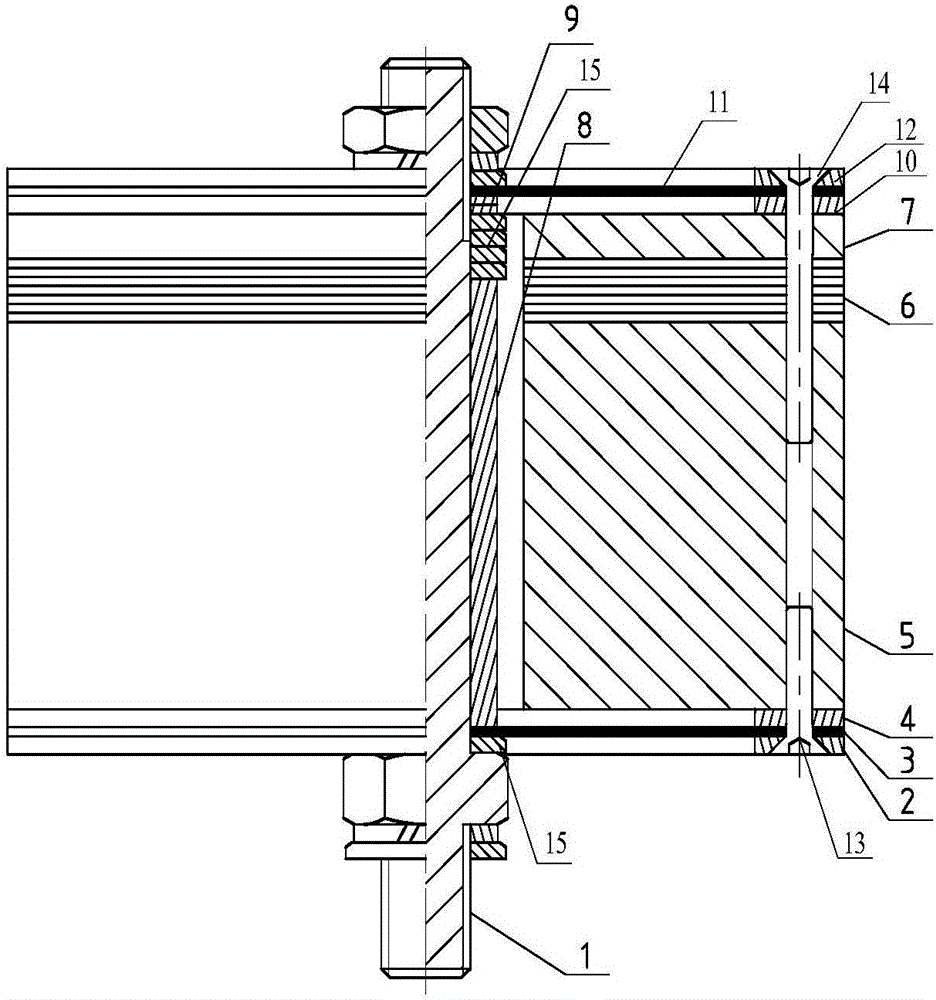

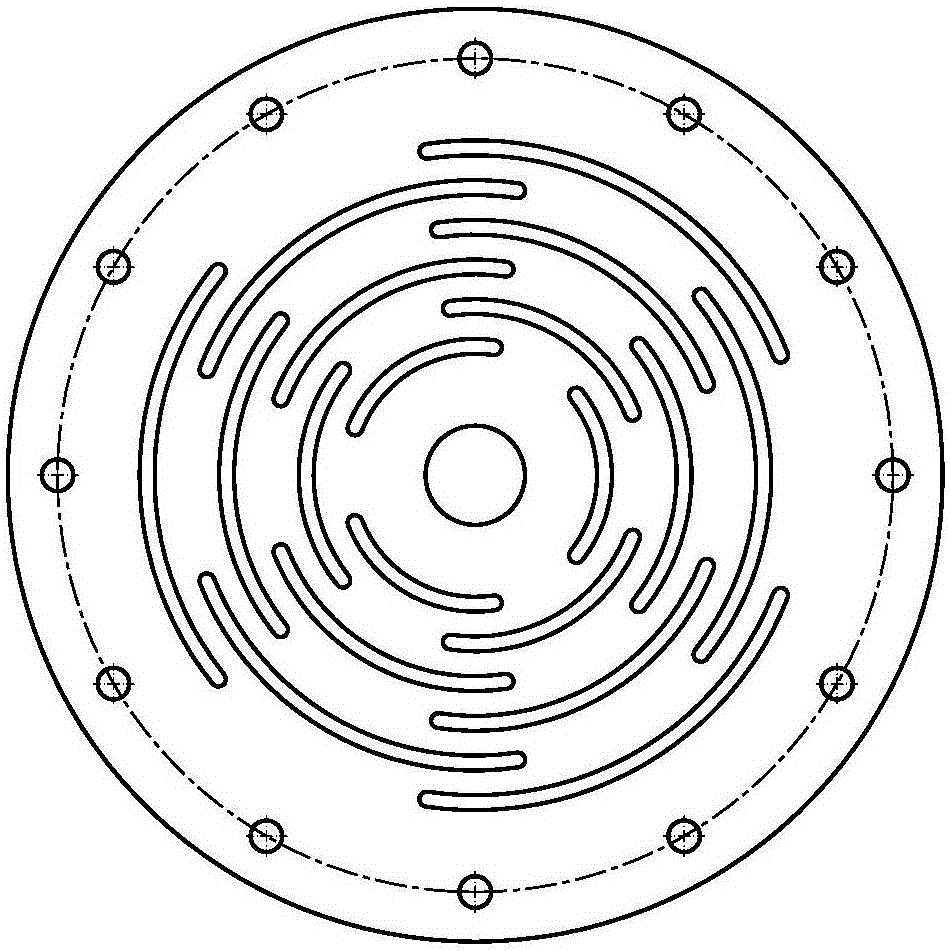

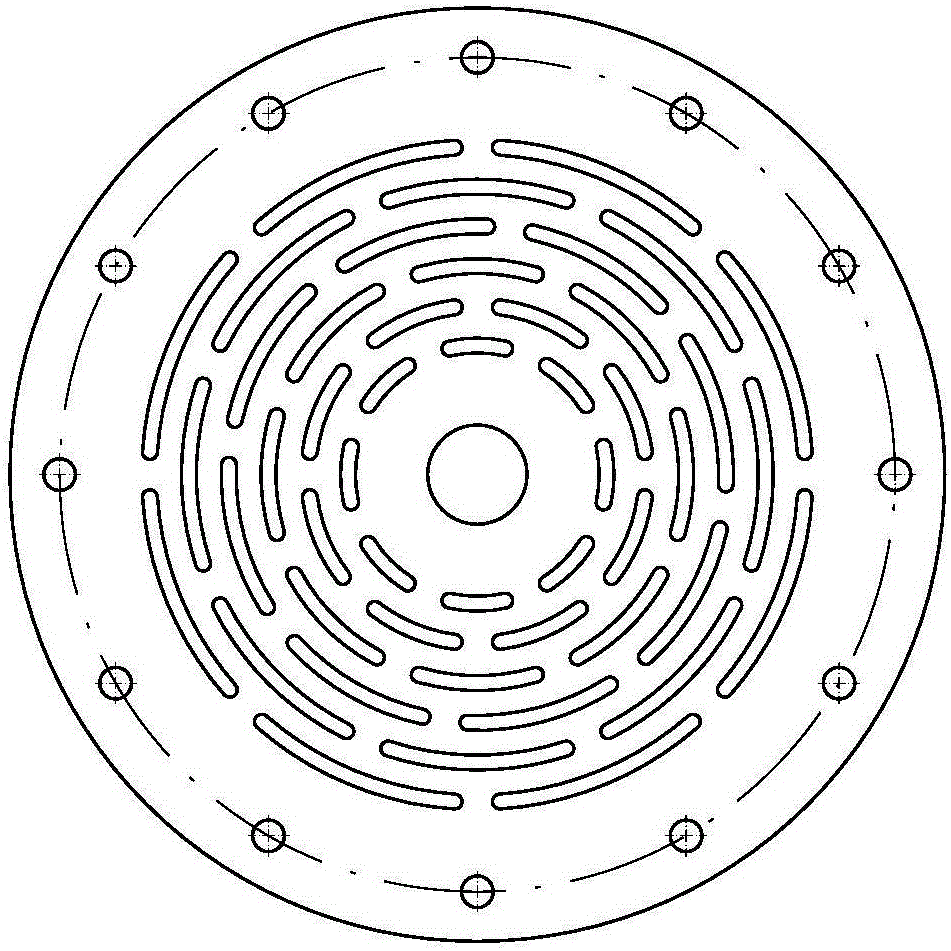

[0019] Referring to the accompanying drawings, a frequency-tunable diaphragm-type shock absorber includes: a support rod 1, a lower outer gasket 2, a lower diaphragm 3, a lower inner gasket 4, a lower mass 5, a frequency-modulating element 6, an upper mass 7, Support column 8, support sheet 9, upper inner washer 10, upper diaphragm 11, upper outer washer 12, first screw 13, second screw 14, flat washer 15;

[0020] The lower part of the support rod 1 has an integrated nut structure; the upper and lower parts of the support rod 1 are threaded, the lower thread is used to fix the frequency-adjustable diaphragm vibration absorber to the equipment, and the upper thread is used to cooperate with the nut to press Tighten the upper diaphragm 11; the upper end of the support rod 1 is higher than the nut installed at this end, so as to adapt to the height change of the frequency modulation element 6 during frequency modulation;

[0021] The lower outer washer 2 and the upper outer wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com