Multi-reverse-slope type stilling pool

A stilling pool and stilling pool floor technology, applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve the problems of a large amount of sediment deposited in the stilling pool, engineering safety, affecting the normal operation of water conservancy and hydropower projects, etc. Strong turbulence, easy maintenance and excellent sand removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

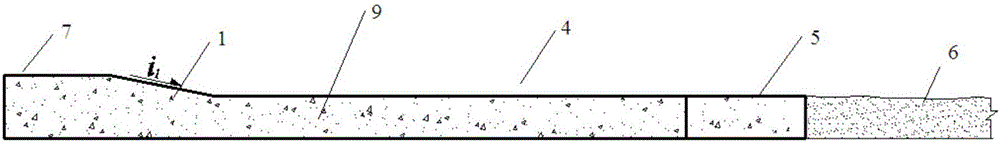

[0026] In this implementation case, the multi-reversed-slope stilling basin is used in a low-head gate-dam hydropower station. The low-head dam-type hydropower station has 3-hole lock chambers 7, each with a width of 8.0m, a gate pier width of 3.0m, and a maximum single-width flow rate of q=100m 3 / s.m.

[0027] The multi-reverse slope stilling pool has a structure such as Figure 1~5 As shown, it is arranged downstream of the barrage and is connected with the barrage through the diversion slope 1. The structure of the stilling pool includes a bottom plate 9 and side walls 8 on both sides of the bottom plate. Connected Haiman 5. Since the hydropower station has a 3-hole sluice chamber, the total number of side wall reverse slopes and sand washing channels is three. Wall reverse slope 2-1, the slope direction of the side wall reverse slope is parallel to the side walls on both sides, and the structure size of the reverse slope of the two side walls is the same. Each end of ...

Embodiment 2

[0031] In this implementation case, the multi-reversed-slope stilling basin is used in a low-head gate-dam hydropower station. The low-head dam-type hydropower station has 4-hole lock chambers, the width of each lock chamber is 9m, the width of the gate pier is 3.0m, and the maximum single-width flow rate is q=80m 3 / s.m.

[0032]The multi-reversed slope stilling basin is arranged downstream of the barrage, and is connected with the barrage through the diversion slope 1. The stilling basin structure includes a bottom plate 9 and side walls 8 on both sides of the bottom plate. The downstream end of the stilling basin is provided with a The stilling pool is connected to the seaman 5 of the downstream riverbed 6 . Since the hydropower station has 4-hole sluice chambers, the total number of reverse slopes and sand washing channels is 5. The specific arrangement is that the bottom plate of the stilling pool is provided with a side wall reverse wall connected with the diversion slo...

Embodiment 3

[0036] In this implementation case, the multi-reversed-slope stilling basin is used in a low-head gate-dam hydropower station. The low-head dam-type hydropower station has 5-hole lock chambers, each with a width of 9m, a gate pier width of 3.0m, and a maximum single-width flow rate of q=110m 3 / s.m.

[0037] The multi-reversed slope stilling basin is arranged downstream of the barrage, and is connected with the barrage through the diversion slope 1. The stilling basin structure includes a bottom plate 9 and side walls 8 on both sides of the bottom plate. The downstream end of the stilling basin is provided with a The stilling pool is connected to the seaman 5 of the downstream riverbed 6 . Since the hydropower station has 4-hole sluice chambers, the total number of reverse slopes and sand washing channels is 5. The specific arrangement is that the bottom plate of the stilling pool is provided with a side wall reverse wall connected with the diversion slope along the two side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com