Arc-shaped division type stilling pool

A stilling pool and separated technology, applied in water conservancy projects, sea area engineering, coastline protection, etc., can solve the problems of downstream energy dissipation facilities not meeting the requirements of economy, high efficiency, safety, and low energy dissipation efficiency, and achieve excellent energy dissipation effect , Improve energy dissipation efficiency and reduce project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

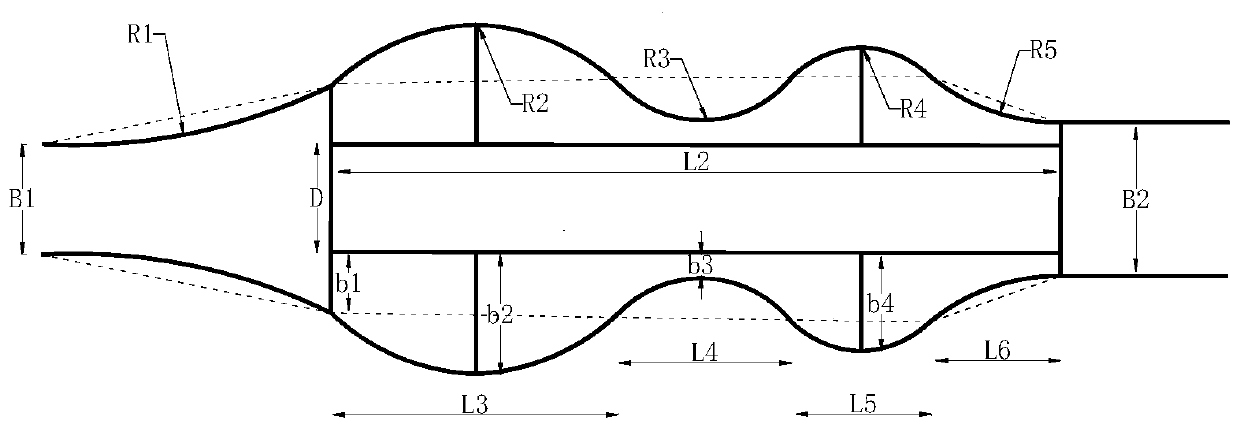

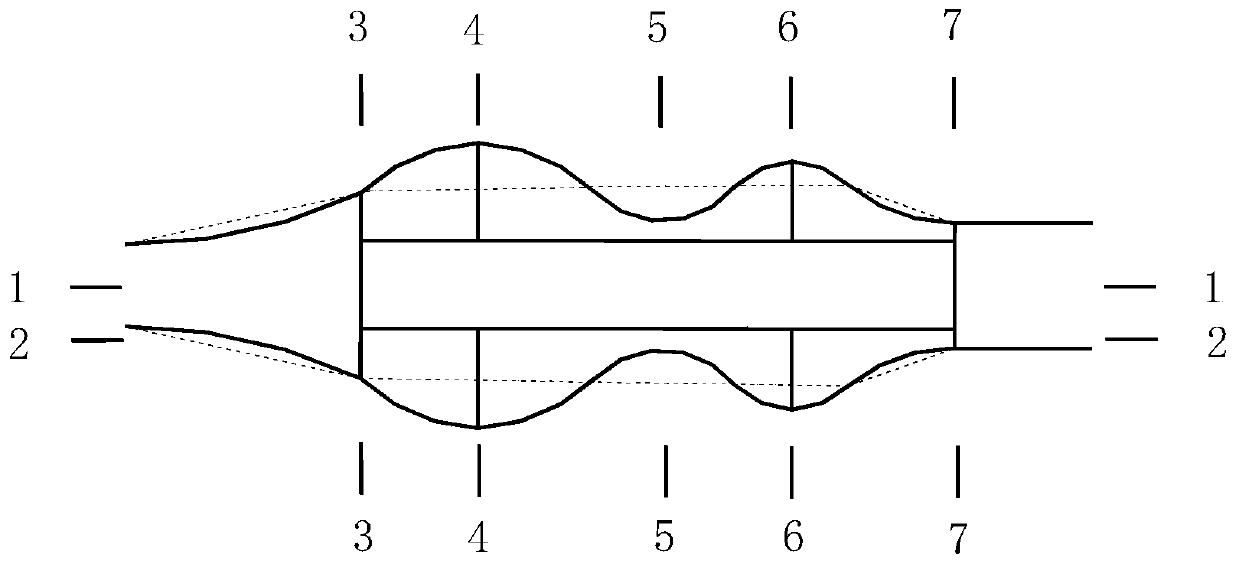

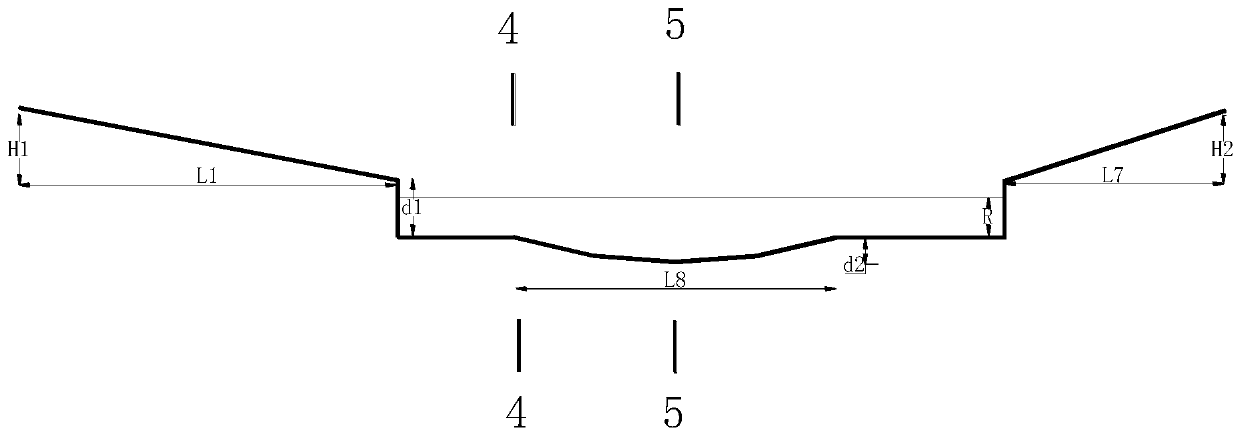

[0031] Such as Figure 1 to Figure 5 As shown, the following describes the composition and structure of each part in detail:

[0032] 1. Positive slope section

[0033] The positive slope section is the initial section of water discharge, and its descending height is H 1 , the horizontal length is L 1 , slope ratio is i 1 =H 1 / L 1 , i 1 ≈0.25~0.4, this slope ratio can ensure that the water discharge speed will not be too fast, and it will enter the stilling pool more stably.

[0034] Furthermore, the positive slope section is an inward arc expansion slope, that is, starting from the initial position, it expands to the end with an inward arc, and the radius of the inward arc is R 1 , the initial position width is B 1 , end width is D+2b 1 (D is the diameter of the bottom surface of the semicircular stilling column, b 1 is the distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com