Double-layer stress absorption band integrated construction train

A technology of stress-absorbing belts and trains, applied in roads, road repairs, roads, etc., can solve the problem that the integrated construction of double-layer stress-absorbing belts is difficult to ensure the thickness and flatness of stress-absorbing belts, and affects the stress absorption of the upper and lower layers Material integration and other issues to achieve the effect of simple structure, simple control, easy installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

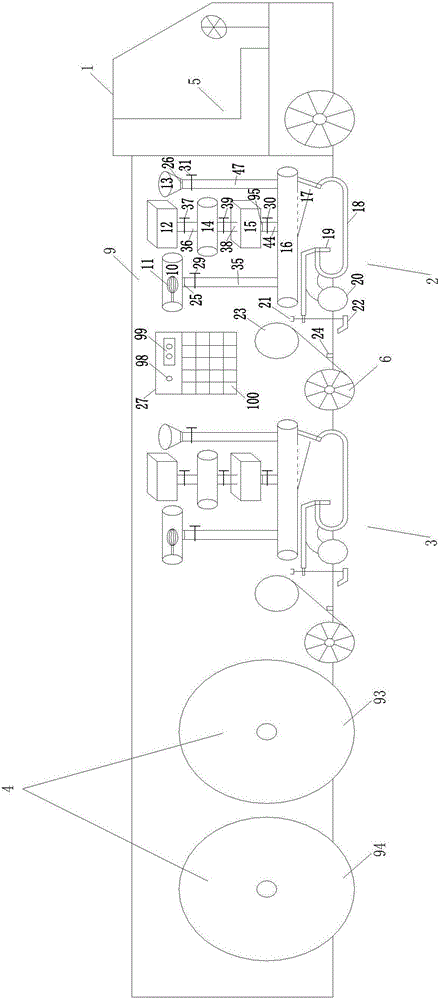

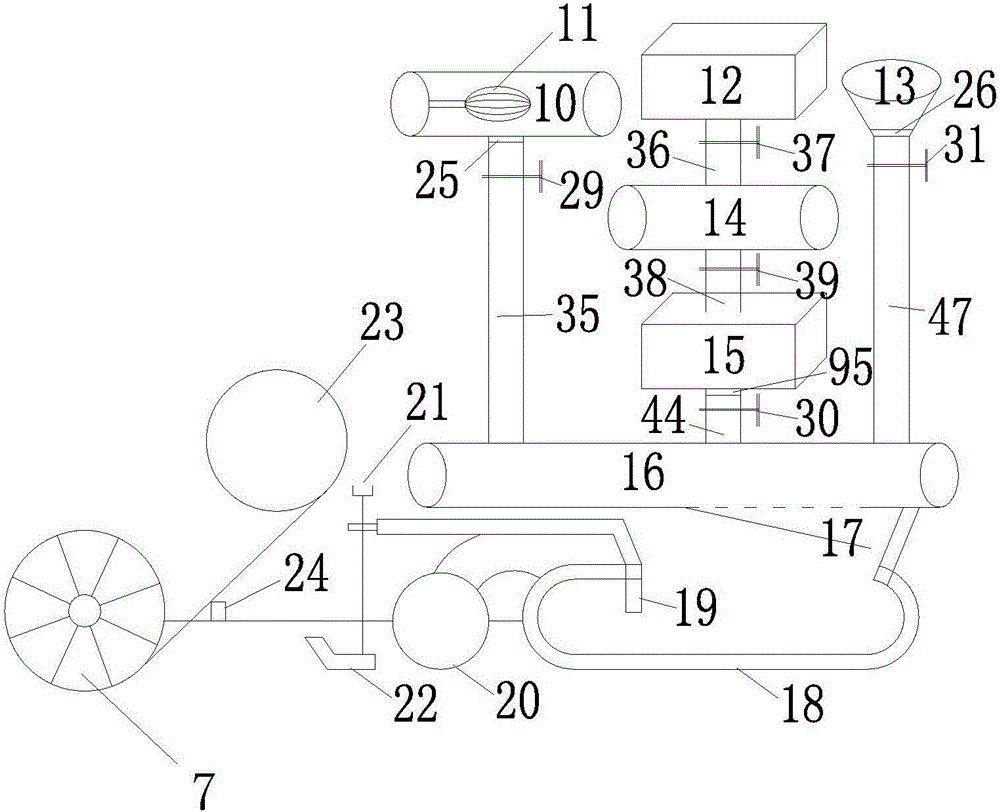

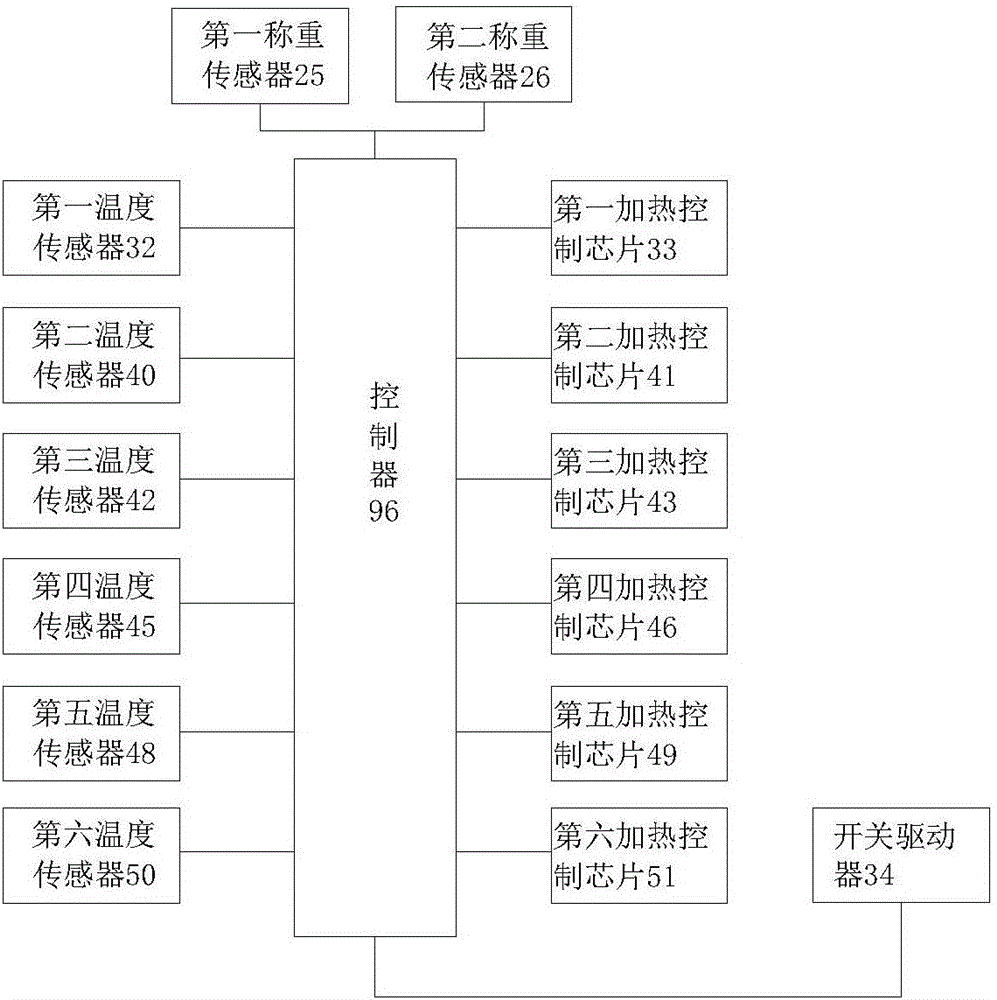

[0025] see figure 1 , the present invention provides a double-layer stress-absorbing belt integrated construction train, the double-layer stress-absorbing belt integrated construction train includes a train body 1 and a carriage 9 dragged by the train body 1; The first layer of stress-absorbing belt preparation and paving device 2, the second layer of stress-absorbing belt preparation and paving device 3, and the compacting device 4 are arranged in sequence in the axial direction; and the paving device 2 and the data acquisition and control device connected to the paving device 2 and the preparation of the second layer of stress-absorbing belt and the paving device 3; the data acquisition and control device includes a control box 27; 96 connected heating control chip and switch driver 34. The control box 27 is provided with a result output screen 99, a parameter input keyboard 100 and a control switch 98 connected with the controller.

[0026] Such as figure 2 as well as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com