Gold nanoparticle array on nickel substrate and preparation method thereof

A gold nanoparticle, gold particle technology, applied in nanotechnology, metal material coating process, superimposed layer plating and other directions, can solve the problem of high cost of large-area highly ordered gold nanoparticle array, and achieve easy industrialization, Mild conditions, large area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

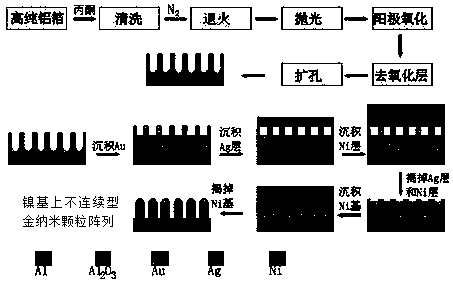

[0031] Embodiment 1: In this embodiment, a brand-new gold nanoparticle array on nickel base is prepared by combining an anodized aluminum oxide template and an electrochemical deposition method, wherein the gold nanoparticles are discontinuous. The specific preparation flow chart is as follows figure 1 shown.

[0032] a. Preparation of anodized aluminum oxide template (AAO)

[0033] Pretreatment of a1 aluminum sheet: ultrasonic cleaning in acetone, deionized water, and ethanol in sequence for 15 minutes, CVD high-temperature annealing, 450~550°C under nitrogen protection, 1.2mA in a mixture of ethanol and perchloric acid at a temperature of 0°C Electrochemical polishing was performed under constant current conditions.

[0034] a2 Anodic oxidation: AAO templates were prepared by a two-step method at a constant voltage of 40-55V using a self-made anodic oxidation device with 0.3M oxalic acid solution as the electrolyte. First anodize the aluminum sheet for the first time, and...

Embodiment 2

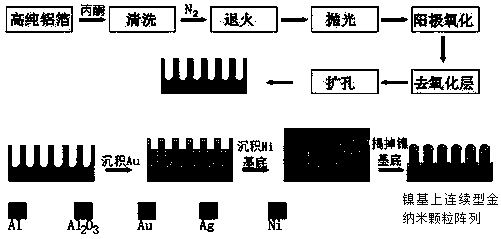

[0040] Embodiment 2: In this embodiment, a brand-new gold nanoparticle array on nickel base is prepared by combining an anodized aluminum oxide template and an electrochemical deposition method, wherein the gold nanoparticles are continuous. The specific preparation flow chart is as follows figure 2 shown.

[0041] a. Preparation of anodized aluminum oxide template (AAO)

[0042] Pretreatment of a1 aluminum sheet: ultrasonic cleaning in acetone, deionized water, and ethanol in sequence for 15 minutes, CVD high-temperature annealing, 450~550°C under nitrogen protection, 1.2mA in a mixture of ethanol and perchloric acid at a temperature of 0°C Electrochemical polishing was performed under constant current conditions.

[0043] a2 Anodic oxidation: AAO templates were prepared by a two-step method at a constant voltage of 40-55V using a self-made anodic oxidation device with 0.3M oxalic acid solution as the electrolyte. First anodize the aluminum sheet for the first time, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com