Process and system for removing phosphorus from vanadium solution in vanadium pentoxide produced from vanadium slag

The technology of vanadium pentoxide and solution is applied to the phosphorus removal process of vanadium pentoxide in the production of vanadium pentoxide from vanadium slag and its system field, and can solve the problems of low utilization rate of equipment, large amount of phosphorus removal agent, low phosphorus removal efficiency and the like. , to achieve high equipment utilization, shorten production time, and good phosphorus removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

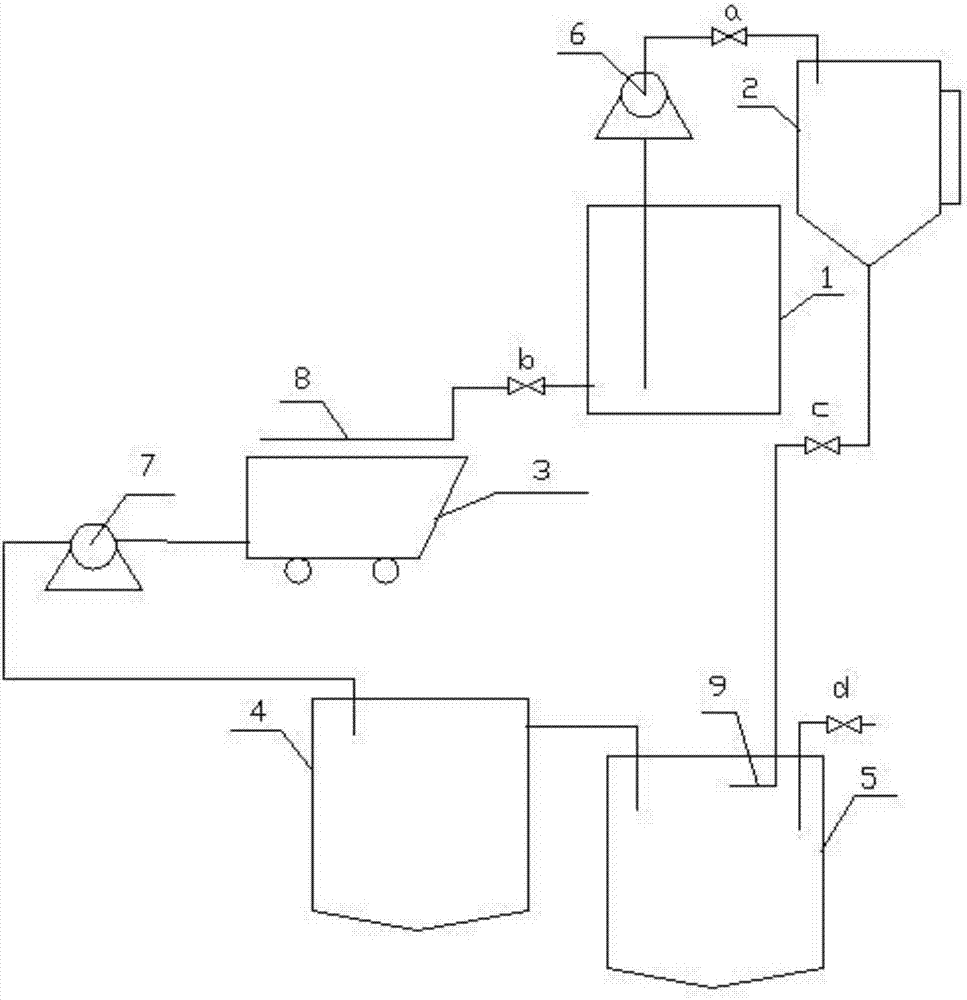

[0027] As shown in the figure, this vanadium slag production vanadium pentoxide dephosphorization process system has a dephosphorization agent storage tank 1, and the dephosphorization agent storage tank 1 is connected with a dephosphorization agent high-level metering tank 2 through a pipeline. The pipeline between the phosphorus removal agent storage tank 1 and the phosphorus removal agent high-level metering tank 2 is provided with an infusion pump 6, and the inlet pipeline of the phosphorus removal agent high-level metering tank 2 is provided with a valve a, and the phosphorus removal agent storage tank 1 passes through the pipeline and The distribution vehicle 3 is connected and is provided with a valve b on the pipeline. The distribution vehicle 3 is connected with the primary concentrator 4 through the pipeline, and a vacuum filter is provided on the pipeline between the distribution vehicle 3 and the primary concentrator 4. Pump 7, the overflow outlet on the upper part ...

Embodiment 2

[0034] The vanadium solution dephosphorization process system for producing vanadium pentoxide from vanadium slag is the same as that in Example 1.

[0035] The dephosphorization process of vanadium solution in the production of vanadium pentoxide from vanadium slag is as follows: before the process system is started, all valves are closed;

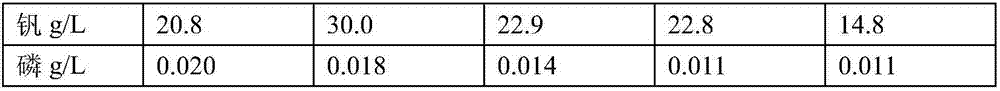

[0036] (1) Put the clinker (containing 0.18wt% phosphorus) after the vanadium slag roasting in the distribution car 3, open the vacuum filter pump 7, rinse with 80 ℃ of water, leaching the clinker for 20min, and obtain the vanadium-containing 30g / L leaching solution, the leaching solution is transported to the primary concentrator 4 through the vacuum filter pump 7, the valve b is opened, and the clinker in the distribution car 3 is rinsed with 160g / L calcium chloride solution in the dephosphorization agent storage tank 1 for 10 minutes, and then chlorinated. The mass ratio of calcium to clinker phosphorus in the calcium solution is 0.5:...

Embodiment 3

[0040] The vanadium solution dephosphorization process system for producing vanadium pentoxide from vanadium slag is the same as that in Example 1.

[0041] The dephosphorization process of vanadium solution in the production of vanadium pentoxide from vanadium slag is as follows: before the process system is started, all valves are closed;

[0042] (1) The clinker (phosphorous 0.0wt9%) after the vanadium slag roasting is loaded in the distribution car 3, the vacuum suction pump 7 is opened, and the clinker is rinsed with 60 ℃ of water, and the clinker is leached for 12 minutes to obtain a vanadium-containing 23g / L leaching solution, the leaching solution is transported to the primary concentrator 4 through the vacuum filter pump 7, the valve b is opened, and the clinker in the distribution car 3 is rinsed with the 120g / L calcium nitrate solution in the phosphorus removal agent storage tank 1 for 6 minutes, and the clinker in the calcium nitrate The mass ratio of calcium to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com