High-weight high-strength phenol formaldehyde foam and preparation method thereof

A phenolic foam, high-strength technology, applied in the field of foam plastics, can solve the problems of limited popularization, easy slag removal, high production cost, and achieve the effects of reducing production cost, low foam density, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

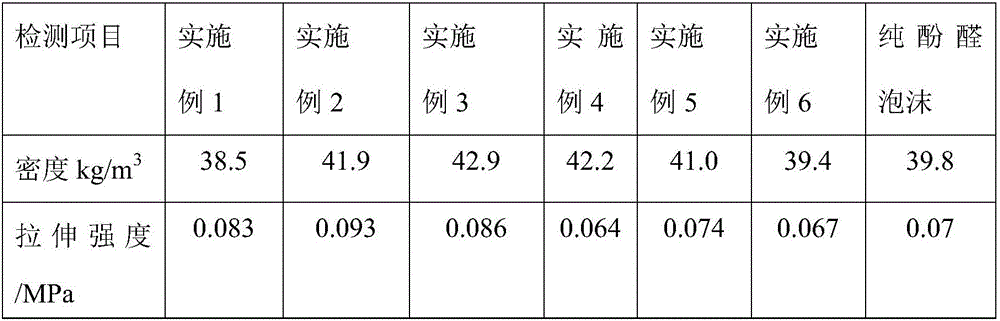

Examples

Embodiment 1

[0027] The lightweight high-strength phenolic foam provided in Example 1 includes the following raw materials in parts by weight: 100 parts of high-viscosity phenolic resin, 4 parts of silica sol, 3 parts of pH regulator, 2 parts of potassium silicate, 5 parts of emulsifier, foaming 7 parts of agent, 12 parts of curing agent.

[0028] The preparation method of the light-weight high-strength phenolic foam includes: firstly mixing the high-viscosity phenolic resin and silica sol evenly, then adding a pH regulator to make pH=11, then adding potassium silicate, emulsifier, foaming agent and curing Each time a substance is added, ensure that it is evenly mixed with other substances, especially when adding a curing agent, increase the speed of the agitator, mix at a high stirring speed, and transfer it to the mold for foaming within one minute.

[0029] The high viscosity phenolic resin has a viscosity of 25000-35000mPa·s.

[0030] The curing agent is a mixture of inorganic acid an...

Embodiment 2

[0032] The present invention proposes a light-weight high-strength phenolic foam, which comprises the following raw materials in parts by weight: 100 parts of high-viscosity phenolic resin, 3 parts of pH regulator, 4 parts of silica sol, 2 parts of potassium silicate, 5 parts of emulsifier, foaming agent 7 parts, 12 parts of curing agent;

[0033] The preparation method of the light-weight high-strength phenolic foam includes: first adjusting the pH of the high-viscosity phenolic resin with a pH regulator to make pH=11, and then adding silica sol, potassium silicate, emulsifier, foaming agent, and curing agent in sequence , every time you add a substance, you should ensure that it is evenly mixed with other substances, especially when adding a curing agent, increase the speed of the agitator, mix at a high stirring speed, and transfer it to the mold for foaming within one minute.

[0034] The high viscosity phenolic resin has a viscosity of 25000-35000mPa·s.

[0035] The curi...

Embodiment 3

[0037] The present invention proposes a light-weight high-strength phenolic foam, which comprises the following raw materials in parts by weight: 100 parts of high-viscosity phenolic resin, 3 parts of pH regulator, 4 parts of silica sol, 2 parts of potassium silicate, 5 parts of emulsifier, foaming agent 7 parts, 12 parts of curing agent;

[0038] The preparation method of the light-weight high-strength phenolic foam comprises: first adjusting the pH of the high-viscosity phenolic resin and the pH of the silica sol with a pH regulator to make the pH = 11, then mixing the two evenly, and then adding silicic acid in turn Potassium, emulsifier, foaming agent, curing agent, every time you add a substance, you should ensure that it is evenly mixed with other substances, especially when adding the curing agent, you should increase the speed of the agitator and mix at a high stirring speed. Minutes to be transferred to molds for foaming.

[0039] The high viscosity phenolic resin ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com