A reaction regeneration system and method for methanol to propylene

A methanol-to-propylene and reaction regeneration technology, which is applied in chemical instruments and methods, catalyst regeneration/reactivation, bulk chemical production, etc., can solve the problem of reducing the conversion rate of methanol, increasing the residence time of olefins in the number of reaction stages, and increasing alkanes and aromatics and other by-products, so as to avoid hydrogen transfer reaction, increase the inlet concentration, and reduce the formation of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

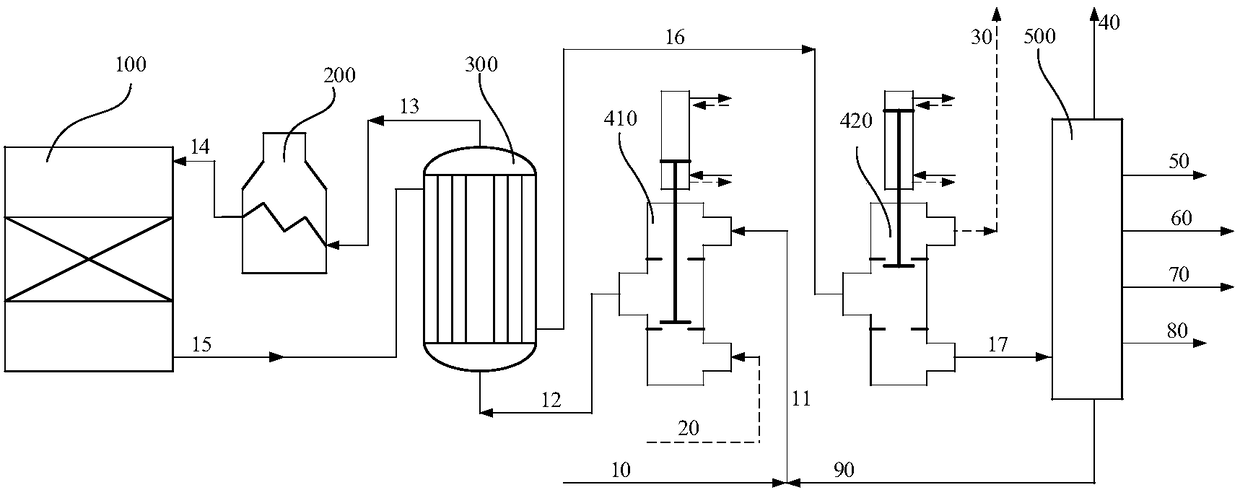

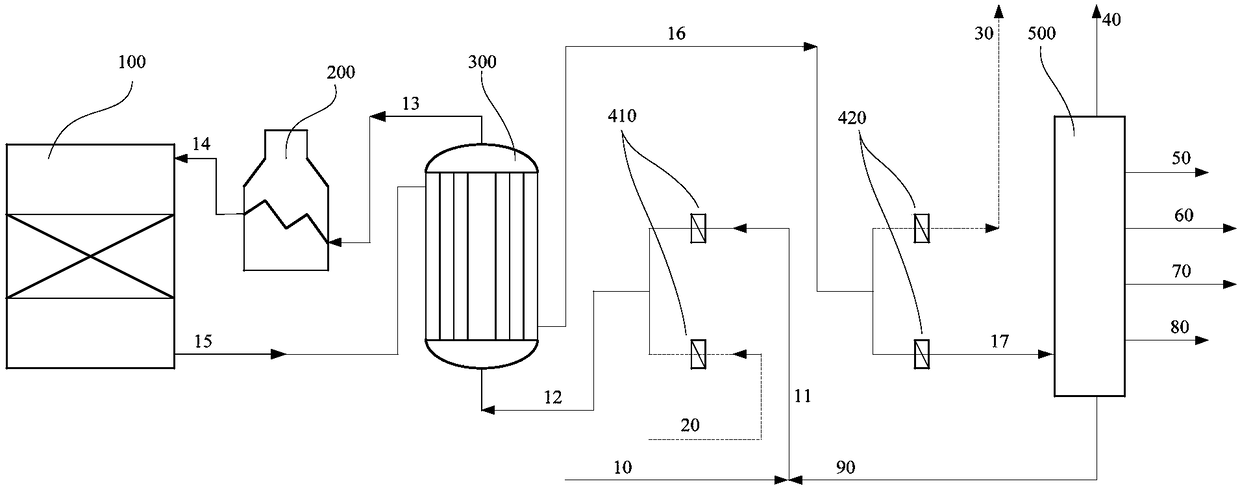

[0070] Such as figure 1 As shown, a methanol-to-propylene reaction regeneration device includes an inlet stream switching valve 410, a tubular heat exchanger 300, a heating furnace 200, a single-stage fixed-bed reactor 100, and an outlet Stream switching valve 420 and separation unit 500. The reactor 100 is filled with 50 tons of catalyst, the catalyst is HZSM-5 type molecular sieve particles, and the Si / Al ratio is 200. Methanol raw material 10 flow rate is 200 tons / hour; Recirculating stream is the mixture of water and hydrocarbon, and flow rate is water 252 tons / hour, C 2 and C 4 -C 6 Hydrocarbon 775 tons / hour. After heat exchange and furnace heating, the temperature of reactant stream 14 is 400°C. After the reaction, the temperature of the reactant stream 15 was 480° C., and the conversion rate of methanol was 99%. After separation, the output of propylene 60 is 76.6 tons / hour, which is equivalent to a selectivity of 87.54% for propylene, 3 tons / hour for fuel gas and...

Embodiment 2

[0073] Such as figure 1As shown, a methanol-to-propylene reaction regeneration device includes an inlet stream switching valve 410, a tubular heat exchanger 300, a heating furnace 200, a single-stage fixed-bed reactor 100, and an outlet Stream switching valve 420 and separation unit 500. Reactor 100 is filled with 50 tons of catalyst, which is ZSM-5 high-silicon molecular sieve particles, and the silicon-aluminum ratio is the same as that in Example 1. Methanol raw material 10 flow rate is 100 tons / hour; Recycle flow is the mixture of water and hydrocarbon, and flow rate is water 126 tons / hour, C 2 and C 4 -C 6 Hydrocarbon 387 tons / hour. After heat exchange and furnace heating, the temperature of reactant stream 14 is 400°C. After the reaction, the temperature of the reactant stream 15 was 480° C., and the conversion rate of methanol was 99.9%. After separation, the output of propylene is 35.6 tons / hour, which corresponds to a selectivity of propylene of 81.37%, 3.5 tons...

Embodiment 3

[0076] Such as figure 1 As shown, a methanol-to-propylene reaction regeneration device includes an inlet stream switching valve 410, a tubular heat exchanger 300, a heating furnace 200, a single-stage fixed-bed reactor 100, and an outlet Stream switching valve 420 and separation unit 500. Reactor 100 is filled with 50 tons of catalyst, which is ZSM-5 high-silicon molecular sieve particles, and the silicon-aluminum ratio is the same as that in Example 1. Methanol raw material 10 flow rate is 400 tons / hour; Recycle flow is the mixture of water and hydrocarbon, and flow rate is water 504 tons / hour, C 2 and C 4 -C 6 Hydrocarbon 1548 tons / hour. After heat exchange and furnace heating, the temperature of reactant stream 14 is 400°C. After the reaction, the temperature of the reactant stream 15 was 480° C., and the conversion rate of methanol was 97%. After separation, the output of propylene is 161 tons / hour, which corresponds to a selectivity of 92.0% for propylene, 5.5 tons / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com