A system and method for preparing hydrogen-rich gas and calcium carbide from carbide slag

A technology of calcium carbide slag and calcium carbide, which is applied in chemical instruments and methods, hydrogen, bulk chemical production, etc., can solve the problems of raw material demand, waste of pyrolysis gas, etc., reduce raw material costs, rationally utilize resources, and improve heat utilization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

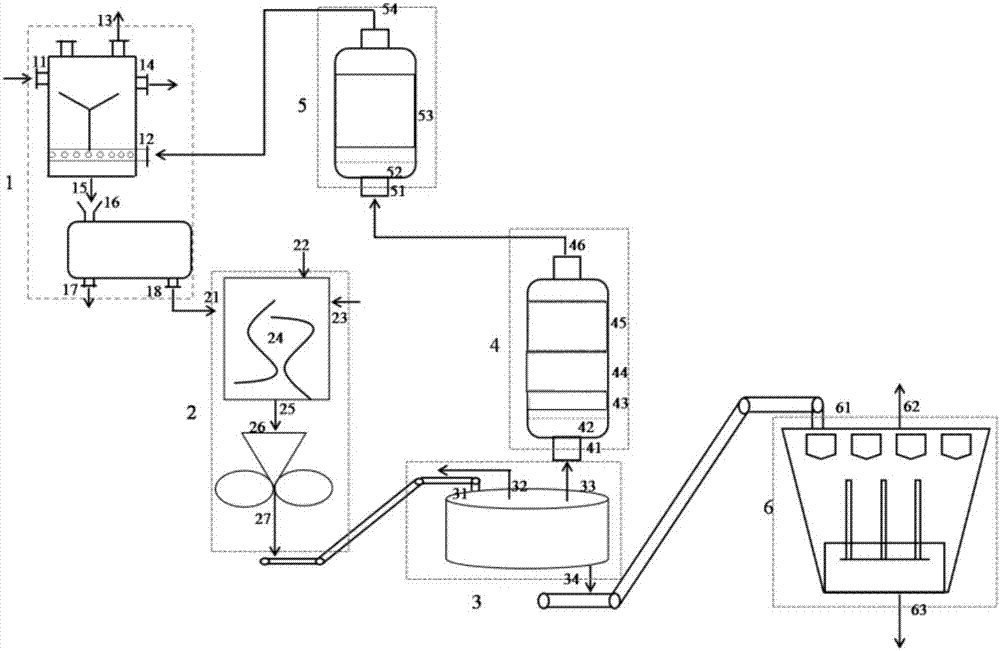

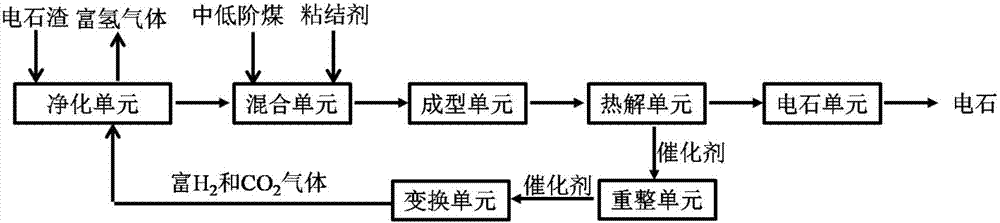

[0043] Using long-flame coal and calcium carbide slag as raw materials, the calcium carbide slag slurry is first added to the purification tank, and the CO-enriched gas delivered by the conversion unit is passed from the bottom of the purification tank to the purification tank while stirring continuously. 2 and H 2 Gas, adjust the pH of calcium carbide slag slurry to 8-11, carbonize calcium hydroxide, the main component in calcium carbide slag, into calcium carbonate, and impurity magnesium oxide react to become water-soluble magnesium bicarbonate. After preliminary precipitation, the carbonized solid is sent to the filter press device to reduce the water content to below 40%, and remove water-soluble impurities, and then the carbonized solid is sent to the mixer, and mixed with coal powder and binder according to 1.2 : 1:0.2 mass ratio mixing, after further stirring, press molding. The shaped balls are sent to the preheating furnace through the screw conveying device, and du...

Embodiment 2

[0045] Using long-flame coal and calcium carbide slag as raw materials, the calcium carbide slag slurry is first added to the purification tank, and the CO-enriched gas delivered by the conversion unit is passed from the bottom of the purification tank to the purification tank while stirring continuously. 2 and H 2 Gas, adjust the pH of calcium carbide slag slurry to 8-11, carbonize calcium hydroxide, the main component in calcium carbide slag, into calcium carbonate, and impurity magnesium oxide react to become water-soluble magnesium bicarbonate. After preliminary precipitation, the carbonized solid is sent to the filter press device to reduce the water content to below 40%, and remove water-soluble impurities, and then the carbonized solid is sent to the mixer, and mixed with coal powder and binder according to 1.8 : 1:0.03 mass ratio mixing, after further stirring, press molding. The shaped balls are sent to the preheating furnace through the screw conveying device, and d...

Embodiment 3

[0047] Using long-flame coal and calcium carbide slag as raw materials, the calcium carbide slag slurry is first added to the purification tank, and the CO-enriched gas delivered by the conversion unit is passed from the bottom of the purification tank to the purification tank while stirring continuously. 2 and H 2 Gas, adjust the pH of calcium carbide slag slurry to 8-11, carbonize calcium hydroxide, the main component in calcium carbide slag, into calcium carbonate, and impurity magnesium oxide react to become water-soluble magnesium bicarbonate. After preliminary precipitation, the carbonized solid is sent to the filter press device to reduce the water content to below 40%, and remove water-soluble impurities, and then transport the carbonized solid to the mixer, and mix it with coal powder and binder according to 1.5 : 1:0.13 mass ratio mixing, after further stirring, press molding. The shaped balls are sent to the preheating furnace through the screw conveying device, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com