A roll film tension adjustment device

A technology of tension adjustment and roll film, which is applied in the field of roll film tension adjustment devices, can solve the problems of difficult tension adjustment, inability to adapt to tension change requirements, elastic force changes, etc., and achieve simplified structure, increased convenience and tension stability , Guarantee the effect of packaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

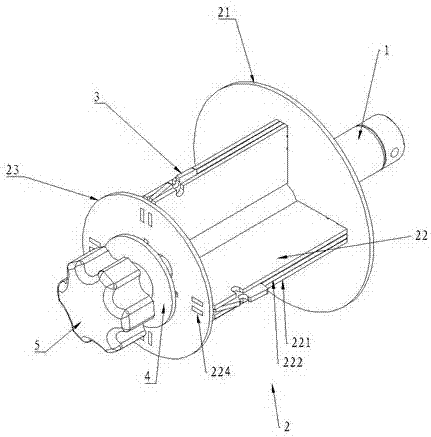

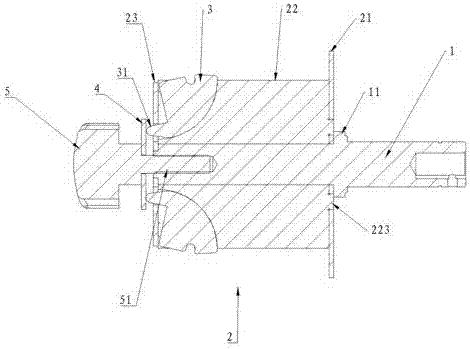

[0029] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended Figure 1 to Figure 2 The technical solution provided by the present invention is described in detail.

[0030] figure 1 It is a structural schematic diagram of the roll film tension adjusting device of the present invention. figure 2 It is a sectional view of the roll film tension adjusting device of the present invention. Please refer to figure 1 and figure 2 As shown, a roll film tension adjustment device is shown, which has such features, including: a base rod 1 , a movable plate installation part 2 , several movable plates 3 , a pressing plate 4 and a knob handle 5 .

[0031] Specifically, a retaining ring 11 is provided on the peripheral surface of the base rod 1 . The movable panel installation part 2 is sheathed on the base rod 1 , and one end of the movable panel installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com