unboxing method

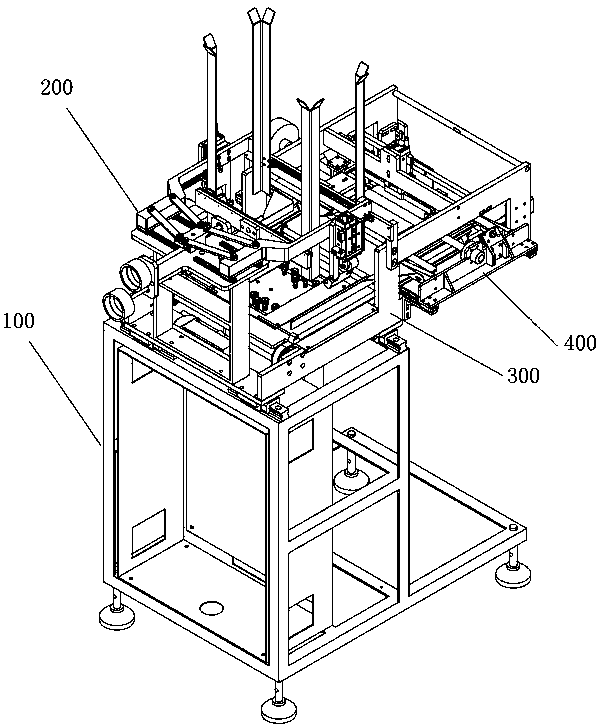

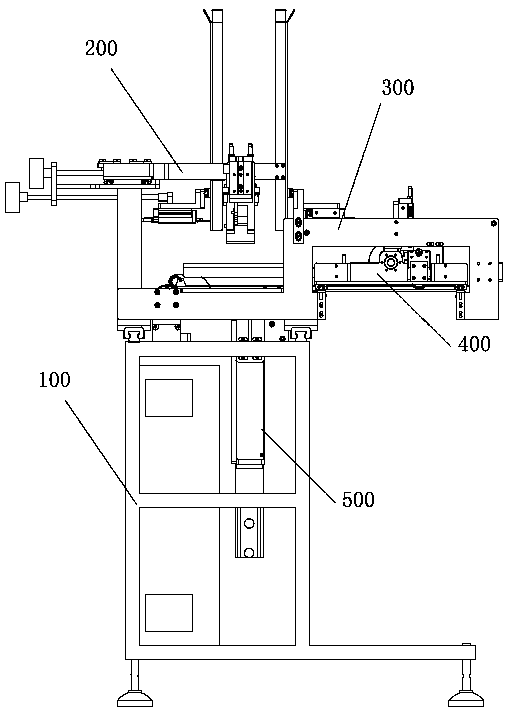

A box-down and bottom-most technology, which is applied in the direction of unstacking, conveyor, transportation and packaging of objects, and can solve problems such as inability to use universal transmission mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] A box lowering method, the lowermost tray among the stacked trays is dropped vertically, the dropped tray is pushed horizontally, and the tray after the horizontal push is pushed downward again, so that the tray falls into the onto the conveyor belt.

Embodiment 2

[0119] A box lowering method, the lowermost tray among the stacked trays falls vertically, the dropped tray is pushed horizontally, and the tray after the horizontal push is pushed downward again, so that the tray falls into the on the conveyor belt.

[0120] Specific steps are as follows:

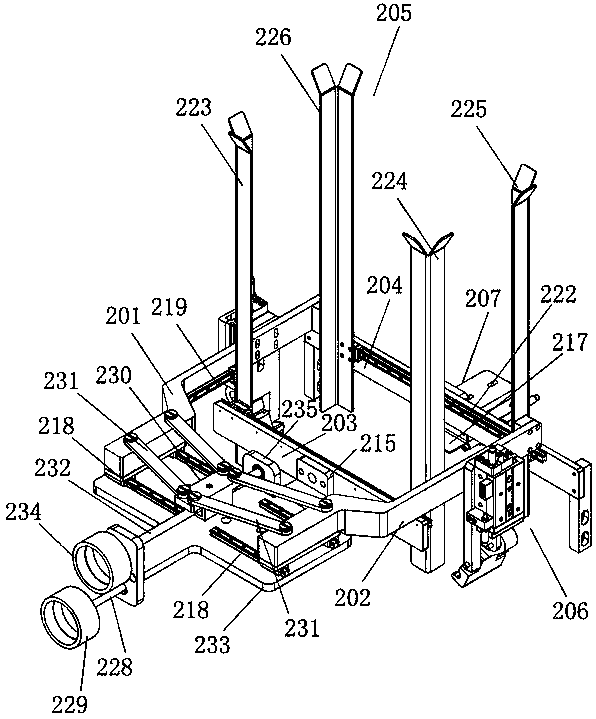

[0121] A. Place the stacked trays in the tray storage space surrounded by the guard plate 205;

[0122] B. At least one fork plate 217 is provided on each of the front, back, left and right sides of the tray storage space, and the two fork plates 217 provided in the front and rear directions are the first group of fork plates 217, and the left and right directions are provided The two fork plates 217 are the second set of fork plates 217, and one set of fork plates 217 in the two sets of fork plates 217 is the rotating fork plate 206. The edge support of the box; the other set of fork plates 217 in the two sets of fork plates 217 is a horizontal fork plate 207, and its working principle ...

Embodiment 3

[0130] A method for lowering boxes, characterized in that: the lowermost tray among stacked trays falls vertically, the tray after falling is pushed horizontally, and the tray after horizontal pushing is pushed downward again, so that the tray The box drops onto the conveyor belt.

[0131] Specific steps are as follows:

[0132] A. Place the stacked trays in the tray storage space surrounded by the guard plate 205;

[0133] B. At least one fork plate 217 is provided on each of the front, back, left and right sides of the tray storage space, and the two fork plates 217 provided in the front and rear directions are the first group of fork plates 217, and the left and right directions are provided The two fork plates 217 are the second set of fork plates 217, and one set of fork plates 217 in the two sets of fork plates 217 is the rotating fork plate 206. The edge support of the box; the other set of fork plates 217 in the two sets of fork plates 217 is a horizontal fork plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com