Large-load underwater releasing and recovering system

A recovery system and large-load technology, applied in the direction of ships, etc., can solve the problems of increasing the test cost and manpower and material resources, damage and release of the releaser, pollution of the test water area, etc., to achieve the effect of easy operation, large release load, and simple system construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

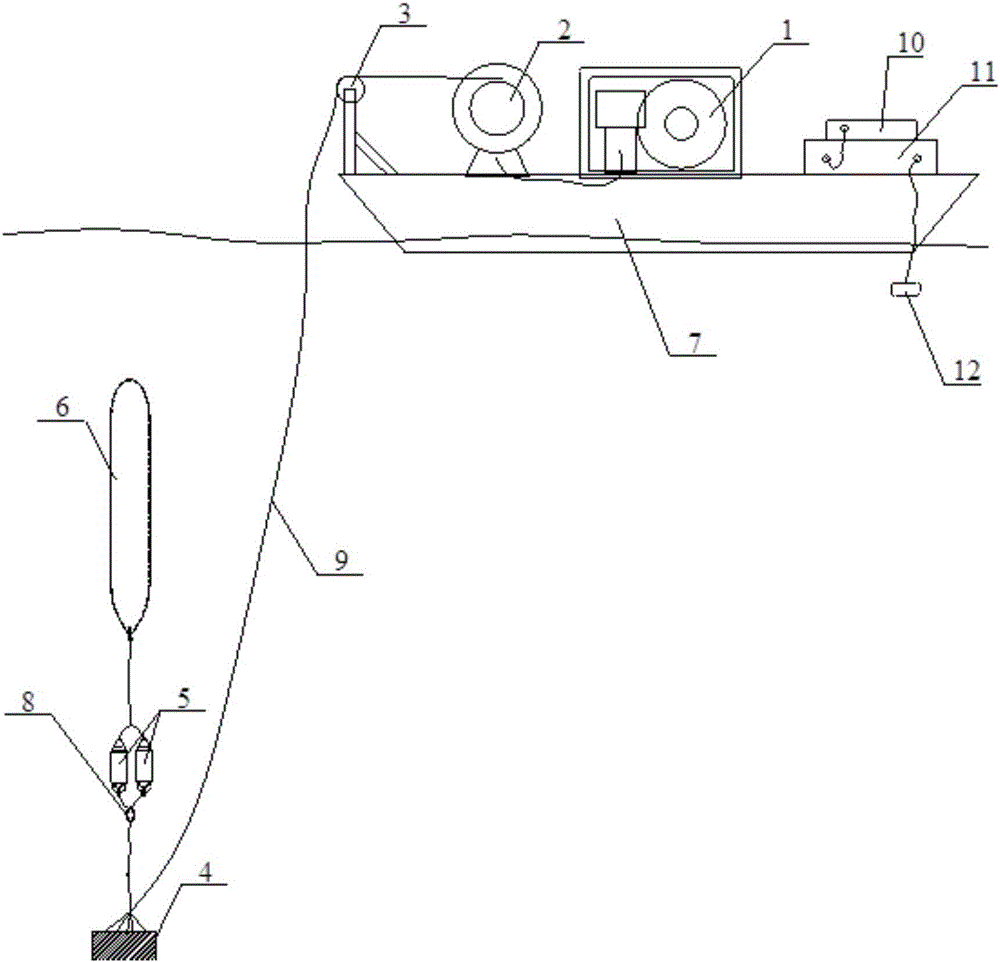

[0014] Refer to the attached drawings, the large-load underwater release and recovery system, which is used to release the experimental model 6 and recover the external counterweight 4. It includes: a test platform 7, a generator 1 and a hoist 2 mounted on the test platform 7 , Guide pulley and bracket 3, signal generator 10, power amplifier 11, underwater release unit 5, and transmitting transducer 12;

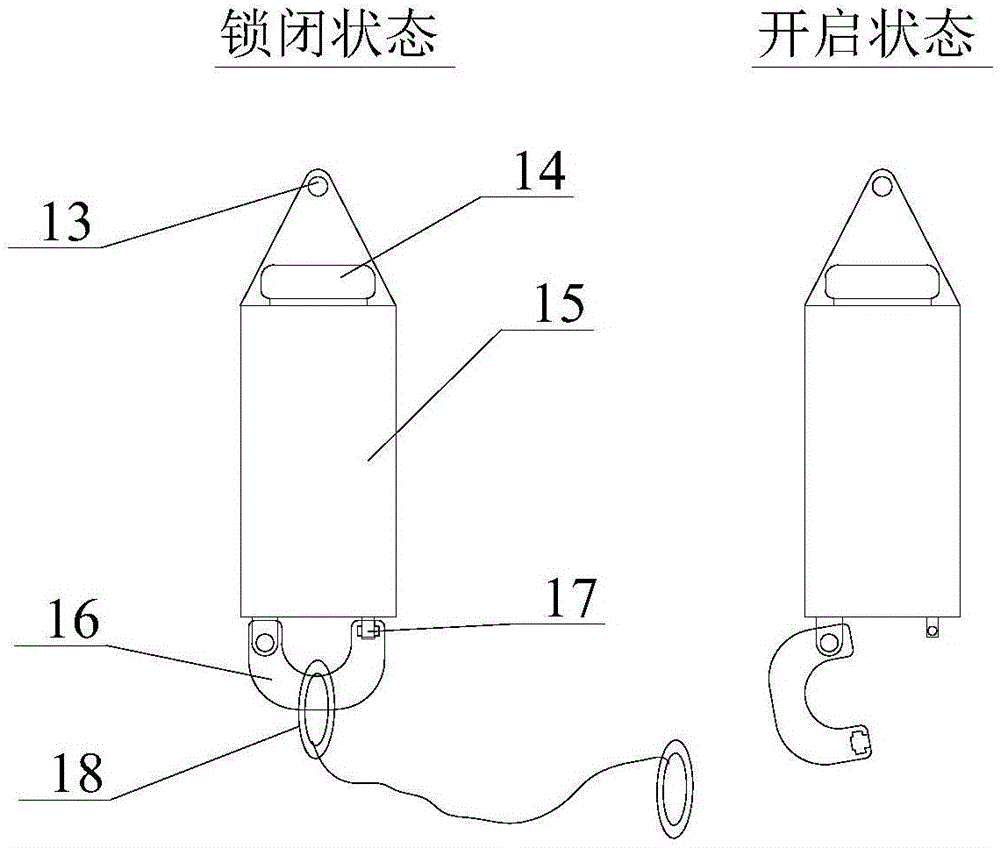

[0015] There are two underwater release units 5, including: a pressure-resistant protective housing 15 with a fixed mounting hole 13 at the top, a release hook 16 and a limit rod 17 connected to the bottom, and installed in the pressure-resistant protective housing 15 The receiving hydrophone 14; the front part of the release hook 16 is provided with a card slot, which cooperates with the limit rod 17, and the limit rod 17 rotates under the control of the internal motor to realize the separation or combination with the release hook 16; The release hook 16 of the two underwater r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com