Electric bicycle front driving wheel assembly with front fork as battery box and mud guard as controller box

A controller box and technology for electric bicycles, applied to fenders, motor vehicles, and rider drives, etc., can solve the problems of complex structure of the whole vehicle and increased space occupation, and achieve small size, large storage capacity, and easy charging. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

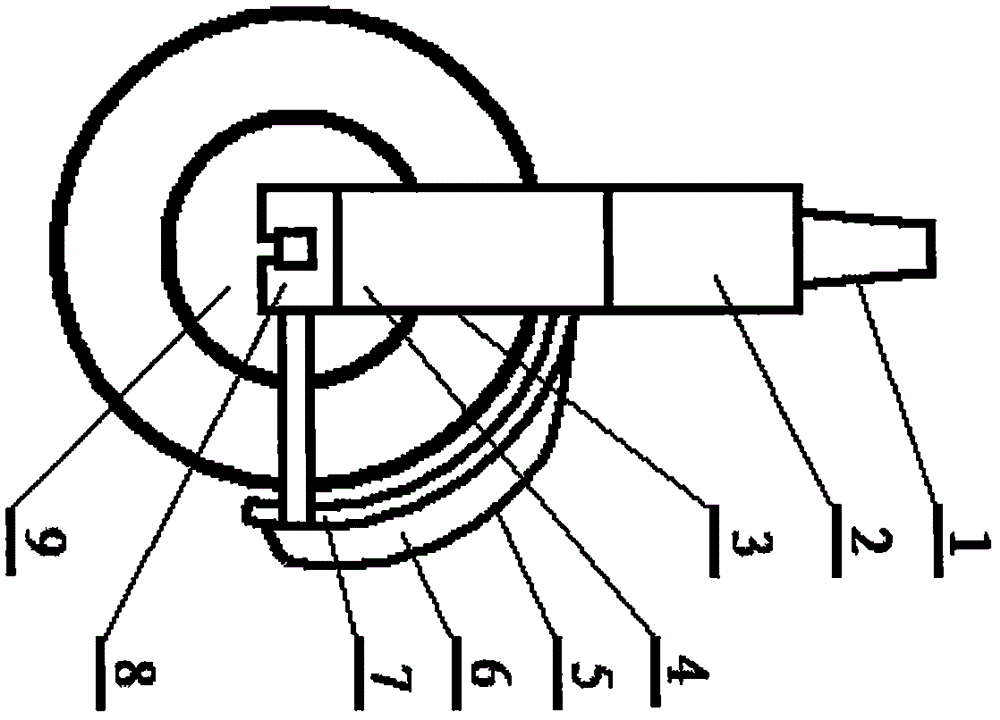

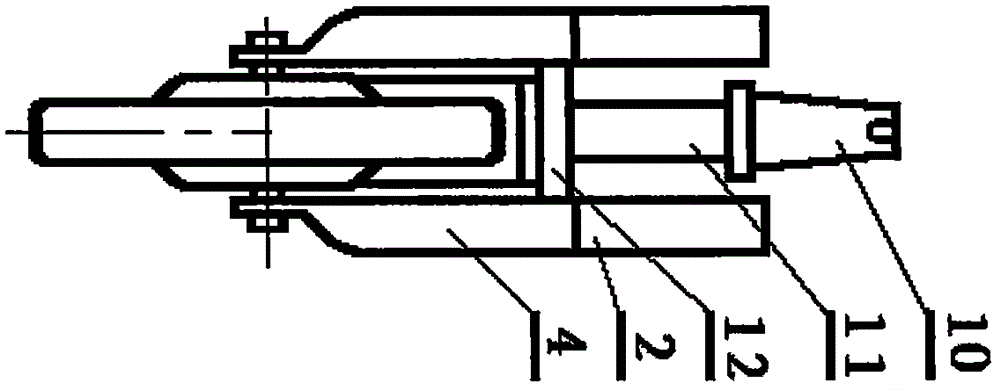

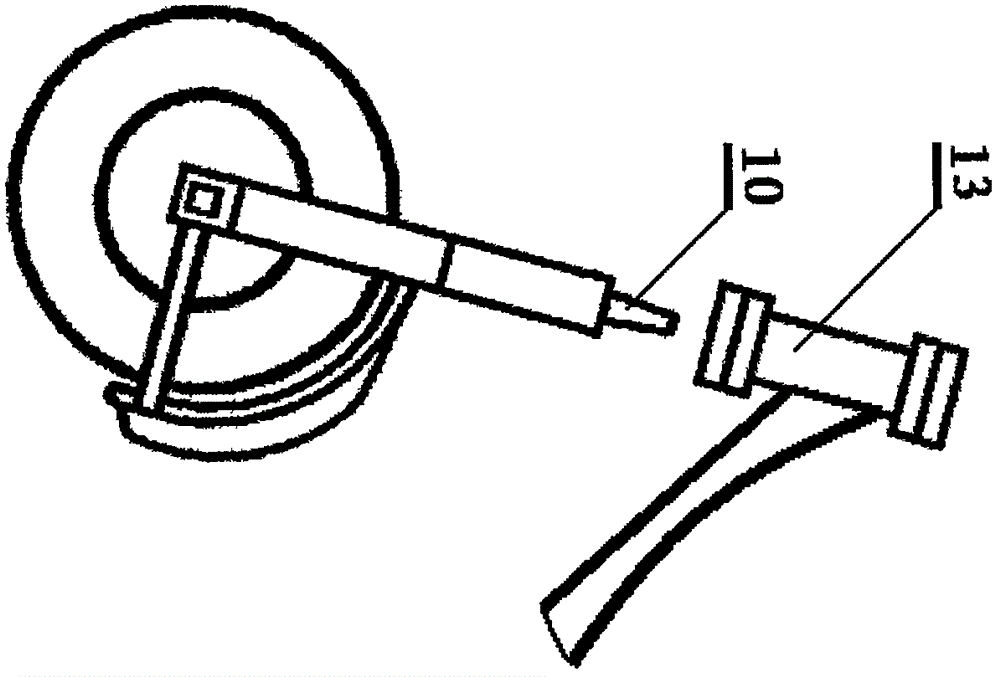

[0010] The whole is composed of a front fork type battery box (3), a fender type controller box (5), a front drive wheel (9), and a member connected to the handlebar (1); the front fork type battery box (3) is composed of the main battery box ( 4), the auxiliary battery box (2) is composed; the bottom end of the main battery box (4) is the front wheel shaft fork (8), and the upper end is inserted into the auxiliary battery box (2); the fender type controller box (5) is composed of the controller box (6) is formed with the fender (7); the member connected to the handlebar (1) is composed of a lower plug joint (10), a vertical tube (11), and a short beam (12), and the short beam (12) is connected to the main battery box horizontally (4); the lower plug connector (10) and the front wheel steering bearing cylinder (13) can be quickly connected and disassembled by plugging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com