ABA double-screw double-machine head film blowing machine

A double-head, film blowing machine technology, applied in the field of improvement and invention, can solve the problems of not simple and compact equipment structure, affecting the quality of blown film products, large equipment space, etc. small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

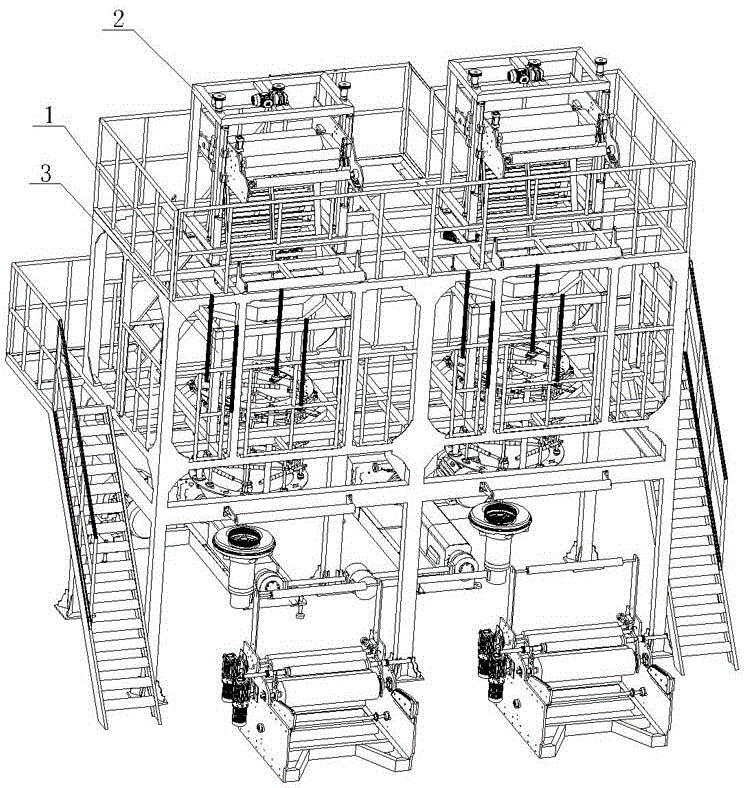

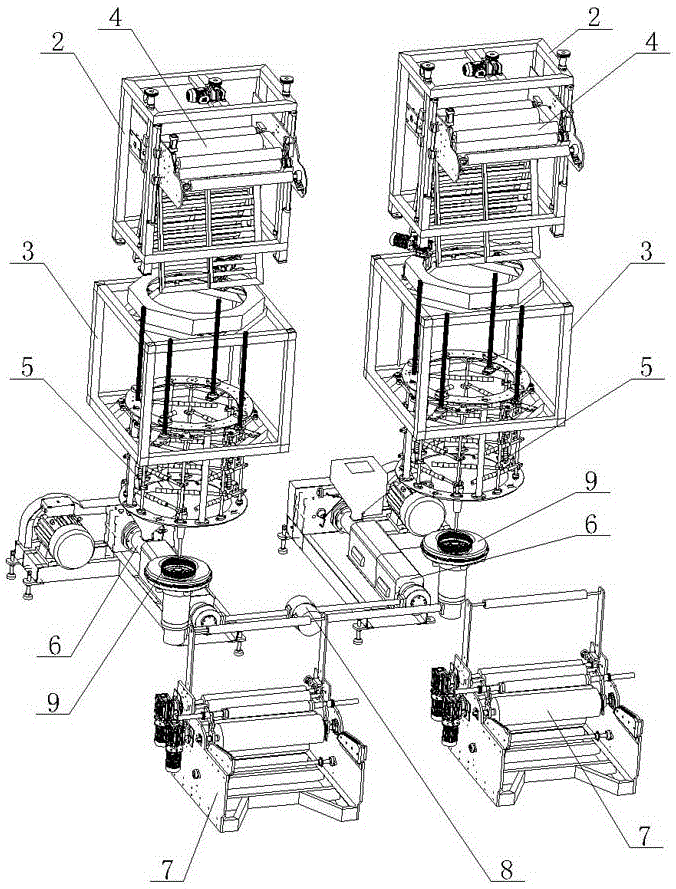

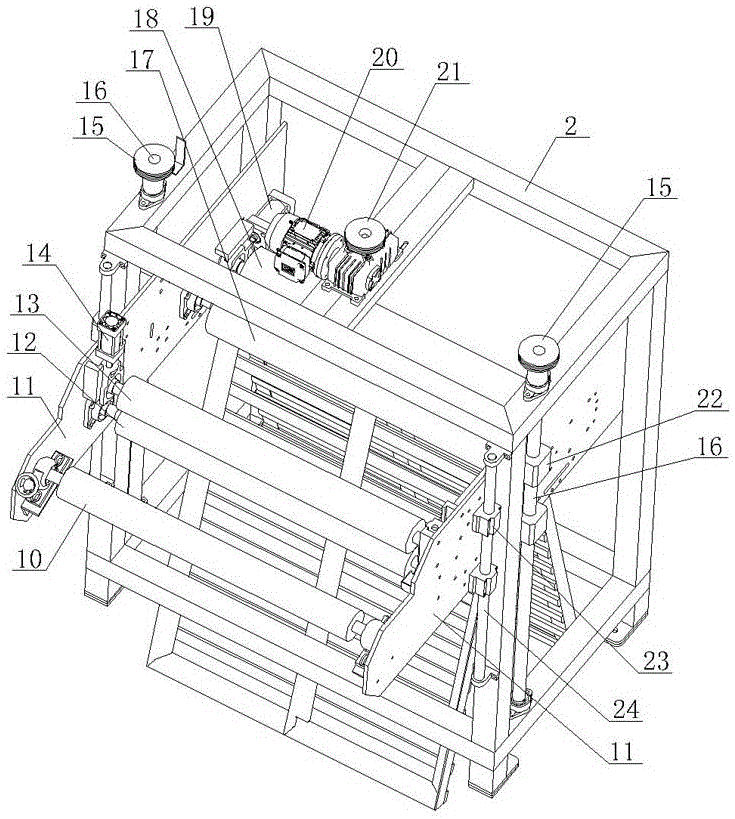

[0012] As shown in the figure, the ABA twin-screw twin-head film blowing machine of the present invention includes a three-layer frame 1 and two sets of identical screw extruding parts 6, film tube forming parts 5, upper traction parts 4 and retracting parts arranged on the left and right. The roll part 7, the second floor of the three-layer frame 1 is fixed with the left and right lower traction brackets 3, the film tube forming part 5 can be adjusted up and down and connected to the bottom of the lower traction bracket 3, and the top layer of the three-layer frame 1 is fixed with the left and right upper traction brackets. The bracket 2 and the upper traction part 4 can be adjusted up and down and connected to the inside of the upper traction bracket 2. Two sets of screw extruding parts 6 are symmetrically arranged on the bottom of the three-layer frame 1. The extrusion ports of the two groups of screw extruding parts 6 are connected to the same Extrusion distribution part 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com