Gypsum slurry thickness fine regulation system and method

A slurry and gypsum technology, which is applied in the field of fine-tuning system for gypsum slurry thickness, can solve the problems of increasing workload, affecting the appearance of boards, and slurry leakage during gypsum board molding, improving automation, reducing human labor, and achieving uniform strength. added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

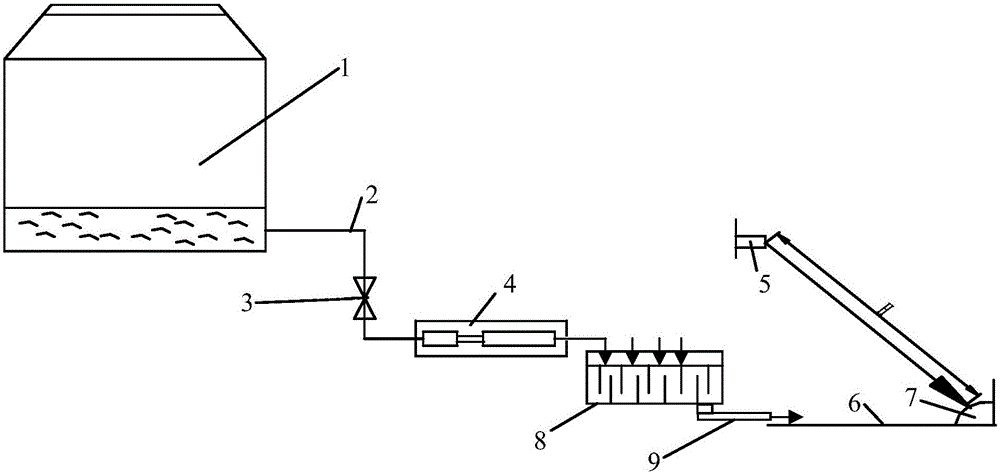

[0032] refer to figure 1 As shown, it is a schematic structural diagram of the gypsum slurry thickness fine-tuning system according to the embodiment of the present invention. The gypsum slurry thickness fine-tuning system includes:

[0033] Tank body 1, delivery pipeline 2, manual valve 3, small flow screw pump 4, distance measuring sensor 5, and frequency converter connected with small flow screw pump 4. The manual valve 3 is opened, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com