Lathe chuck with axial end surface retaining device

A technology of a stop device and a lathe chuck, which is applied in the field of mechanical devices, can solve the problems that the degree of stability affects the quality of processing, the trouble of clamping workpieces, and the quality of processing, and achieves the advantages of convenient operation, high processing efficiency and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

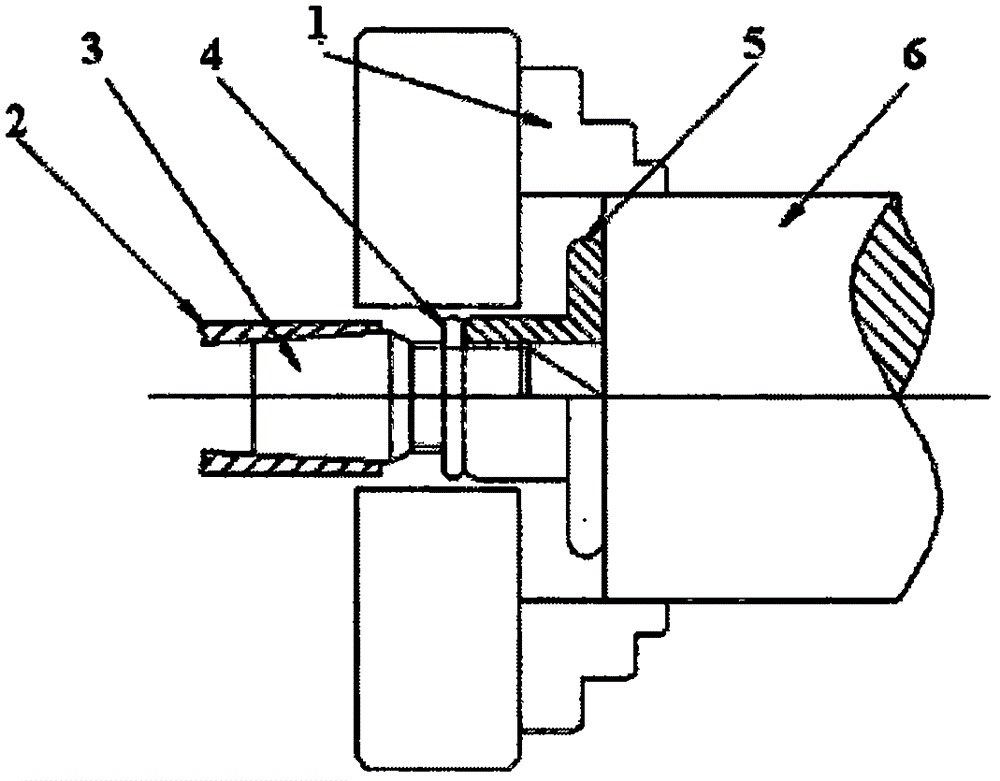

[0017] like figure 1 As shown, a lathe chuck with an axial end face stop device, it includes a chuck body (1), a main shaft (2), a tip body (3) installed on the main shaft (2), and a tip body (3) installed on the tip body ( 3) on the lock nut (4); installed on the tip body (3), the screw stop sleeve (5) located at the right end of the lock nut (4), the tip body (3) extends into the chuck body (1 ) to withstand the workpiece (6), the right end surface of the screw stop sleeve (5) is a plane or a plane with threads.

[0018] In the aforementioned lathe chuck with an axial end stop device, the main shaft (2) is installed on the lathe. The lock nut (4) is installed on the tip body (3) through threads.

[0019] In the above-mentioned lathe chuck with an axial end face stop device, the screw stop sleeve (5) is installed on the tip body (3) through threads.

[0020] In the above-mentioned lathe chuck with an axial end stop device, the chuck body (1) is a three-jaw chuck.

[0021]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com