Syrup filter

A filter and syrup technology, applied in the direction of mobile filter element filter, filtration separation, chemical instruments and methods, etc., can solve the problems of difficult disassembly and assembly, difficult cleaning, clogging of mesh holes, etc., and achieves simple structure and easy production. maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation will be described below in conjunction with the accompanying drawings.

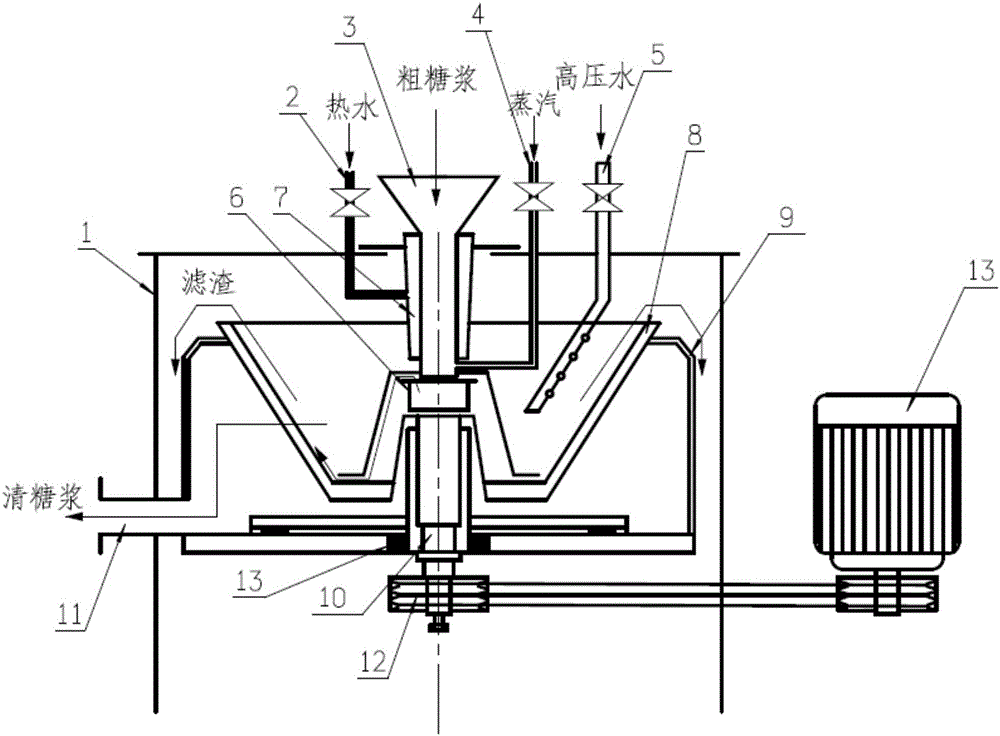

[0020] Such as figure 1 As shown, the syrup filter in this embodiment includes a sieve basket 8 for filtering syrup and a driving mechanism for driving the sieve basket to rotate.

[0021] The sieve basket 8 is a W-shaped revolving body. The upper end of the outer wall of the sieve basket 8 is inclined to the outside. There are filter mesh holes on the outer wall. There is a hollow cone truncated upward from the bottom of the sieve basket 8. There is a vertical cone inside the cone. To the vertical shaft 10, the upper end of the vertical shaft 10 is fixedly connected with the screen basket 8, and the lower end is connected with a driving mechanism such as a variable frequency motor 13 through a pulley 12 and a belt. A barrel-shaped dispenser 6 is fixed on the cone, the upper opening of the dispenser 6 faces upwards, and the side wall of the dispenser 6 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com