Infrared heating device and electric heating appliance

A technology of infrared heating and infrared heating film, which is applied in the field of infrared heating devices and electric heating appliances, can solve the problems of uneven heating and heating carriers that cannot meet the conditions of use, and achieve consistent heating power, equal resistivity, and consistent resistivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

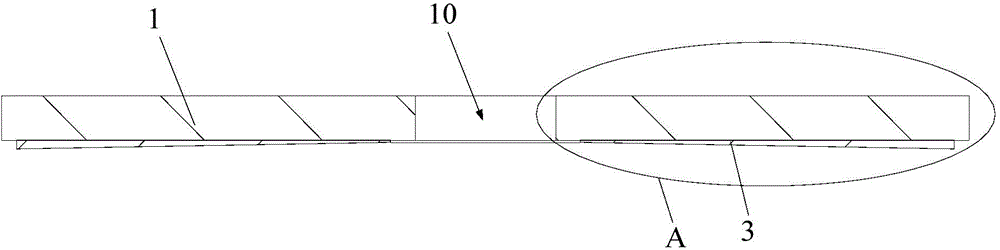

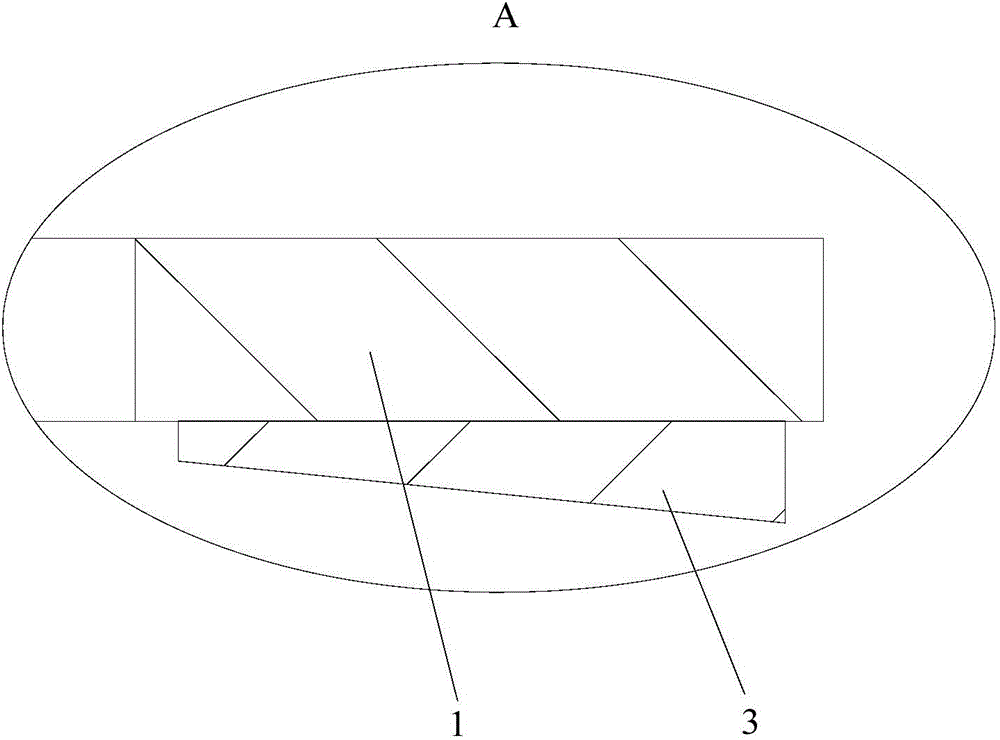

[0049] Such as Figure 2a and Figure 2b As shown, the surface of the infrared heating film layer 3 is a slope.

[0050] The surface of the infrared heating film layer is inclined, and the thickness of the infrared heating film layer increases from the center of the insulating carrier to the edge of the insulating carrier successively. This method increases the thickness of the infrared heating film layer near the edge of the insulating carrier. The cross-sectional area of the longitudinal section keeps the ratio of the length of the infrared heating film to the cross-sectional area equal at the center of the insulating carrier and the edge of the insulating carrier, thereby ensuring that the ratio of the length of the infrared heating film to the cross-sectional area is constant everywhere Keep equal, so that the resistivity of the infrared heating film is basically unchanged. This design ensures that the resistivity of the infrared heating film between the two electrodes ...

Embodiment 2

[0052] Such as Figure 3a and Figure 3b As shown, the surface of the infrared heating film layer 3 is a stepped surface.

[0053] The surface of the infrared heating film layer is a stepped surface, and the thickness of the infrared heating film layer increases sequentially from the center of the insulating carrier to the edge of the insulating carrier. In this way, the infrared heating film layer near the edge of the insulating carrier is enlarged. The cross-sectional area is also conducive to ensuring that the heating power of the infrared heating device is consistent everywhere. Moreover, compared with processing the surface of the infrared heating film layer into an inclined plane, using the stepped surface instead of the inclined plane can reduce the difficulty of the process.

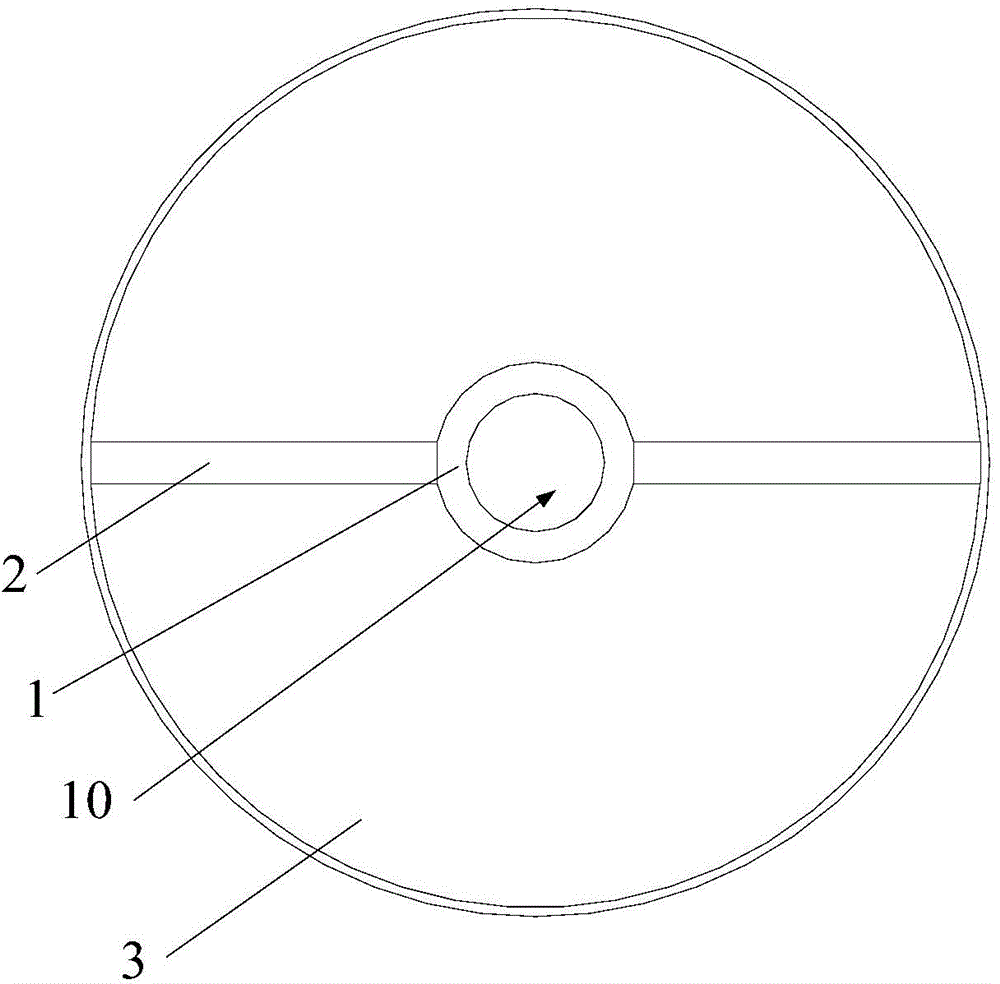

[0054] In one embodiment of the present invention, as figure 1 As shown, the insulating carrier 1 is circular, the cross-section of the infrared heating film layer 3 is ring-shaped, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com