Centrifugal pendulum vibration control device

A vibration-damping device, vibrator-type technology, applied in the direction of shock absorbers, inertia effect shock absorbers, springs/shock absorbers, etc., can solve the problems of increasing the weight and size of the damper and reducing the acceleration performance of the vehicle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

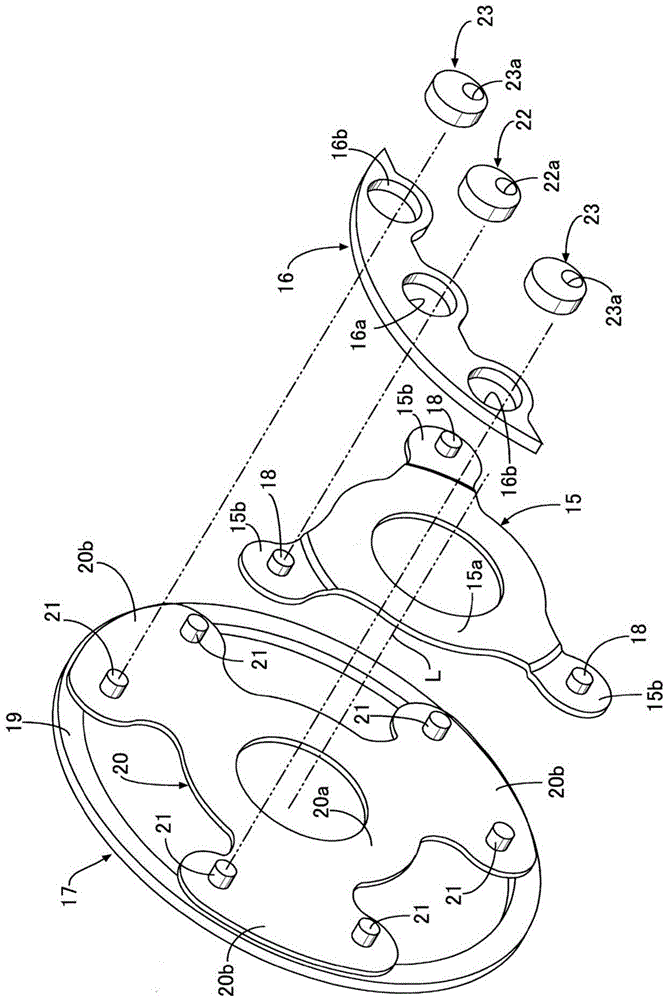

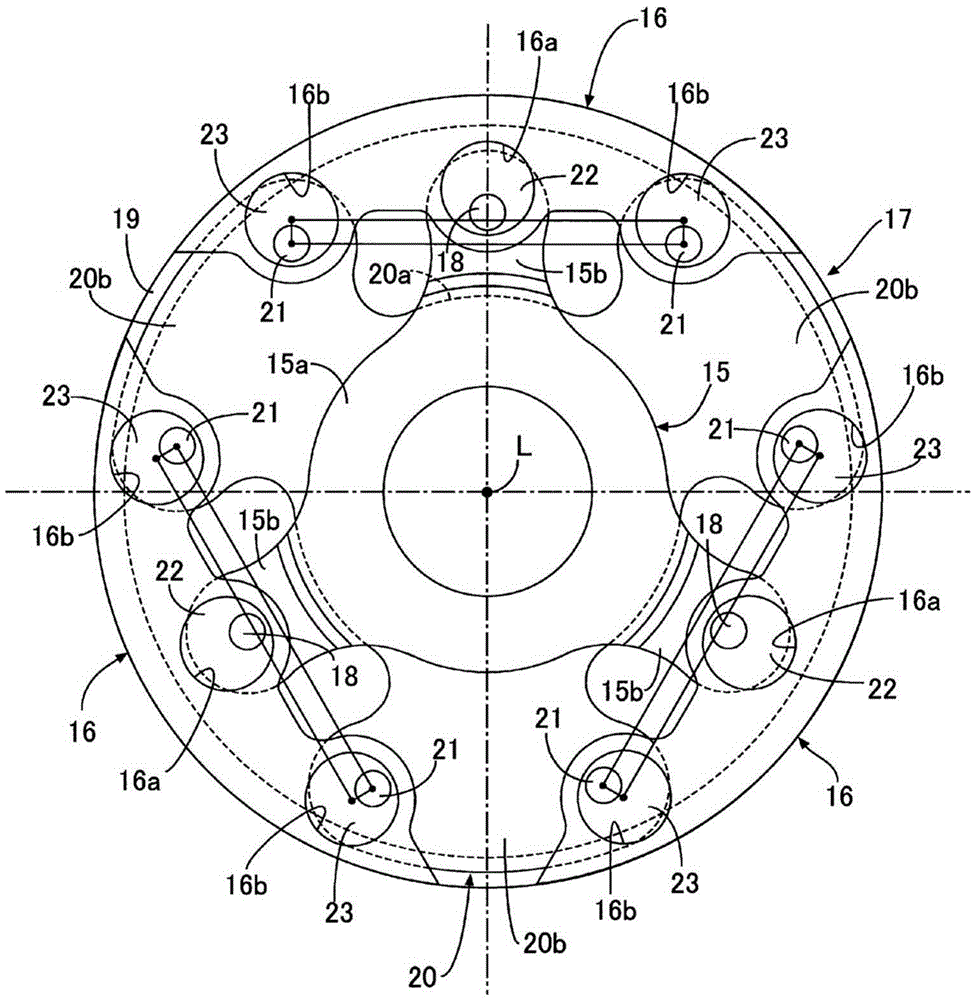

[0024] Below, according to Figure 1 to Figure 7 Embodiments of the present invention will be described.

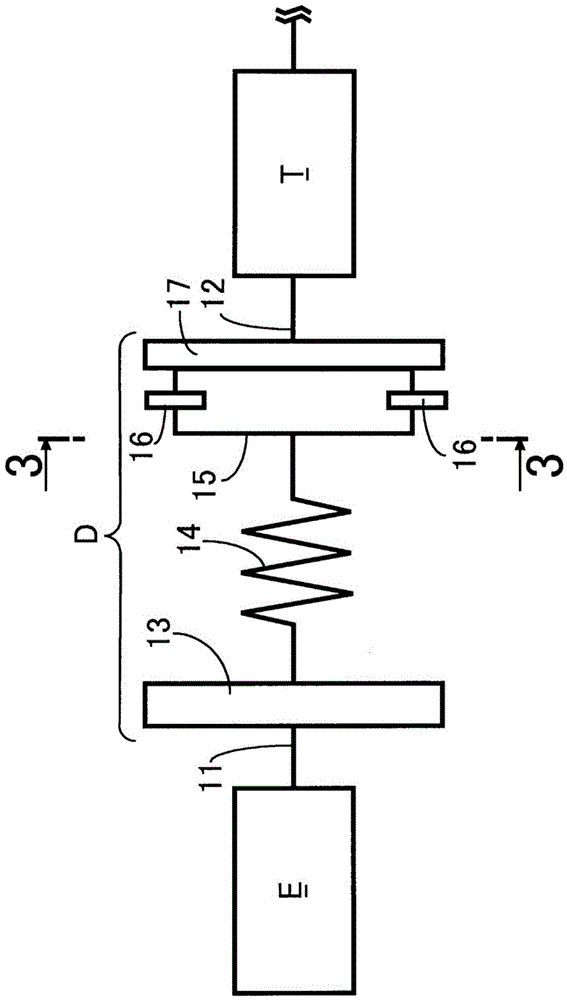

[0025] Such as figure 1 As shown, the damper D is arranged between the crankshaft 11 of the engine E of the automobile and the main shaft 12 of the transmission T. The damper D has: a primary flywheel 13 connected to the crankshaft 11; connected to the The hub portion 15 on the primary flywheel 13; the three first inertial mass bodies 16 connected to the hub portion 15 in a relatively rotatable manner in the circumferential direction; and a secondary flywheel that cooperates with the primary flywheel 13, and The ring-shaped second inertial mass body 17 is connected to the three first inertial mass bodies 16 . . . relatively freely in the circumferential direction.

[0026] Such as Figure 2 to Figure 5 As shown, the hub portion 15 is formed by pressing a sheet metal material, and has an annular support portion 15a and three arm portions 15b protruding radially outward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com