Full automatic film coating and breaking device

A fully automatic, film-cutting technology, applied in packaging, transportation and packaging, packaging/bundling items, etc., can solve problems such as loosening of packaged goods, falling of film heads, and signal interference in three-dimensional warehouses, achieving good results and prolonging service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

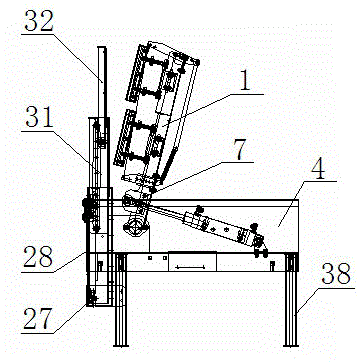

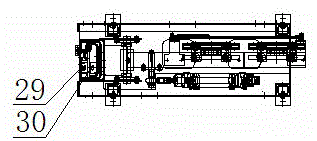

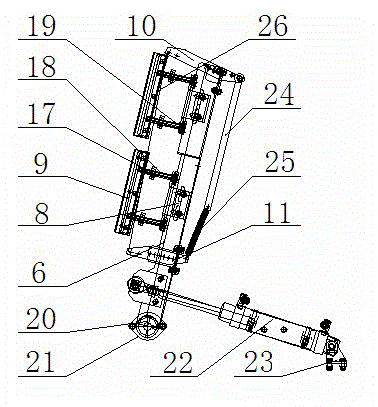

[0021] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a welding and breaking film mechanism 1, a film clamping mechanism 2 and an air blowing mechanism 3. The welding and breaking film mechanism 1 is installed on the first frame 4, and the film clamping mechanism 2 and the blowing mechanism 3 are installed on the second frame 5 Above, the welding and breaking membrane mechanism 1 is provided with an overturning bracket 6, and the overturning bracket 6 is fixed on the first frame 4 through the overturning mechanism 7. The overturning bracket 6 is provided with two connecting plates 8, and the connecting plates 8 are respectively provided with welding The membrane module 9, the two ends of the overturning bracket 6 are respectively equipped with a heating wire upper bracket 10 and a heating wire lower bracket 11; On the cylinder connecting plate 14, a gear assembly 15 is installed on the cylinder connecting plate 14; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com