Presser used for vegetable dehydrating

A press machine and vegetable technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of small amount of pressing at one time, slow pressing speed, affecting the quality and processing of pickles, and achieve the effect of improving drainage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

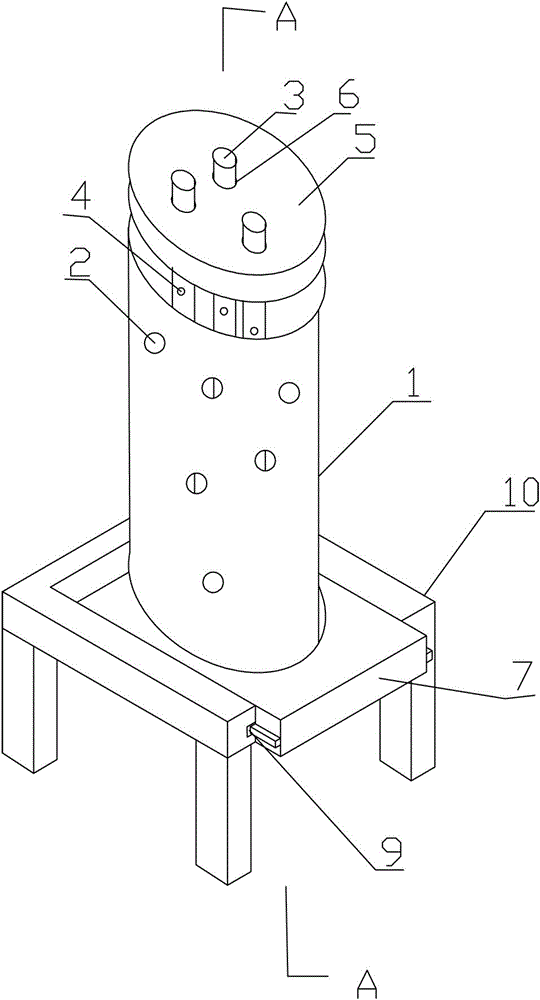

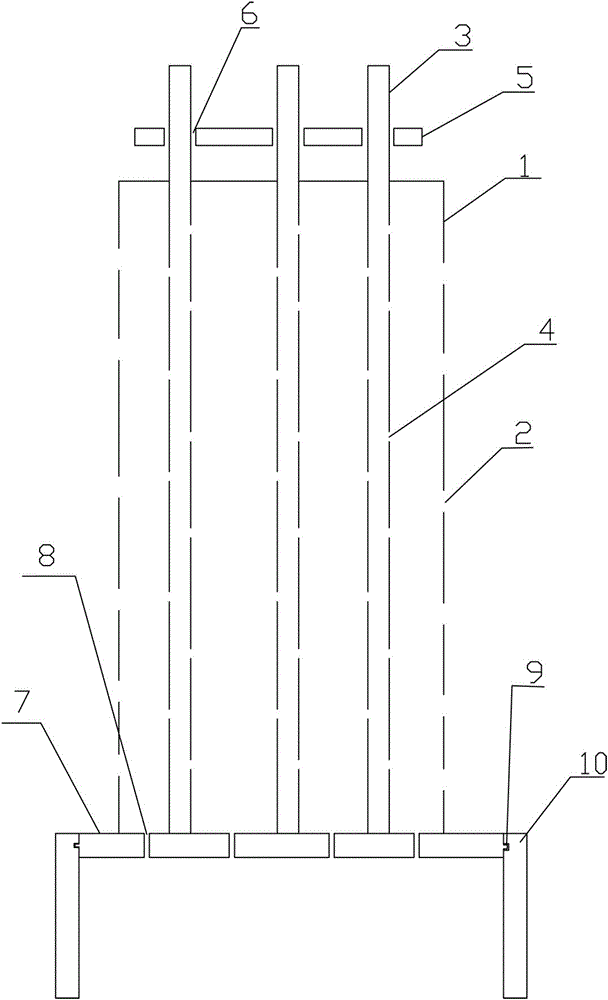

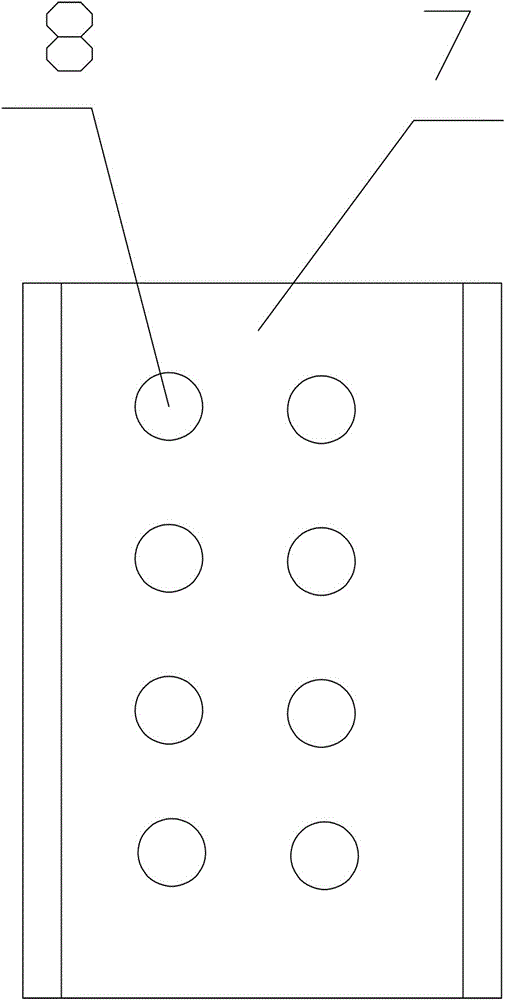

[0023] Such as figure 1 , 2 Among them, a press for dewatering vegetables includes a cavity 1 with two ends open. Preferably, the cavity 1 is arranged on a support 10, and the surface of the cavity 1 is provided with a first water-permeable hole 2. In the cavity 1, there are Three filter tubes 3 parallel to each other (four, five or more filter tubes 3 can be set according to the needs), the filter tubes 3 are vertically arranged in the cavity 1, and the surface of the filter tubes 3 is provided with a second permeable hole 4, The filter tube 3 communicates with the air intake device, and during operation, the vegetables to be squeezed are placed between the cavity 1 and the filter tube 3;

[0024] A compression plate 5 is opened on the upper port of the cavity 1, and three sliding holes 6 are arranged on the compression plate 5. The compression plate 5 is mechanically connected with the driving device, and each sliding hole 6 corresponds to a filter tube 3, and the compressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com