Core-pulling self-locking mechanism of injection mold

An injection mold and self-locking technology, applied in the field of core-pulling self-locking mechanism, can solve problems such as increasing costs, prolonging production cycle, and occupying mold space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

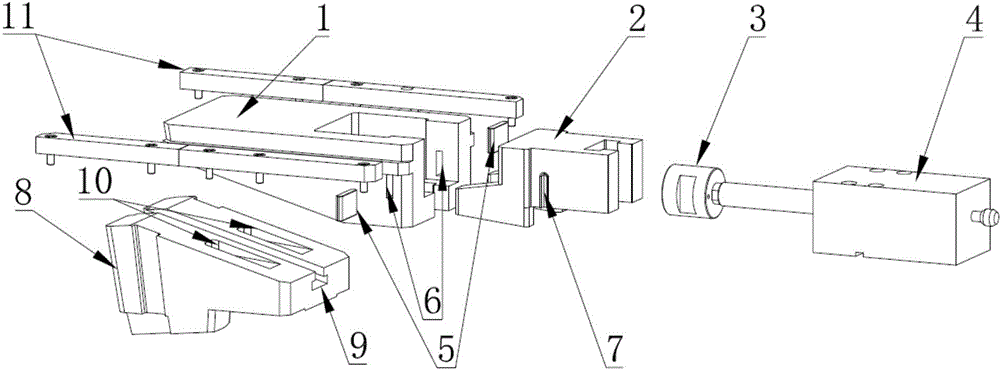

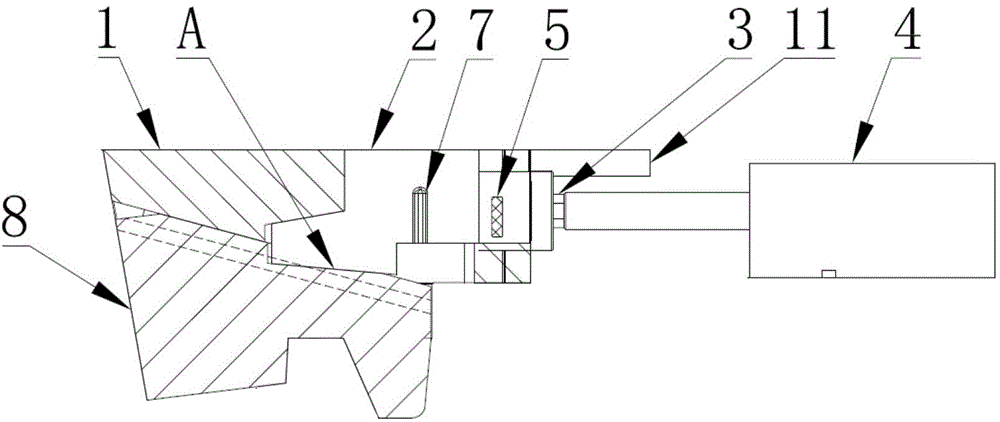

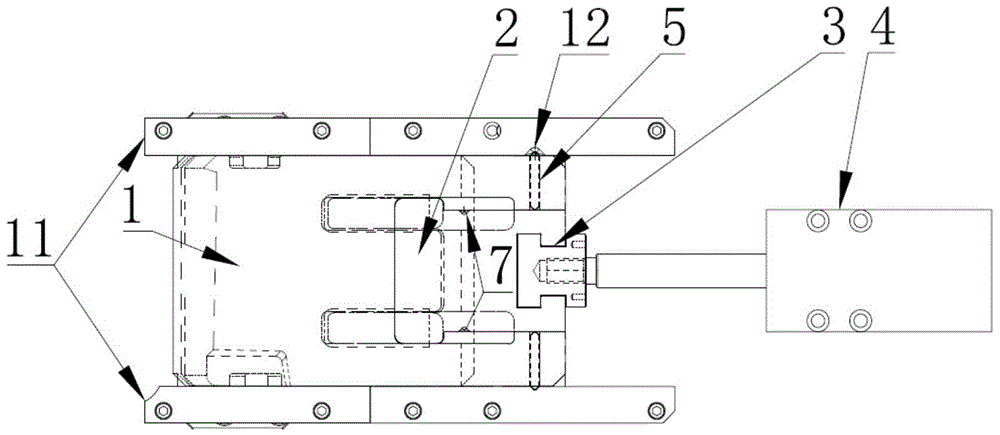

[0028] A core-pulling self-locking mechanism for an injection mold, comprising a wedge block 1, a small wedge block 2, a core-pulling block 8 and a drive unit, the drive unit drives the small wedge block 2 to perform linear reciprocating motion, and the wedge block 1 is provided with a through hole 6, and a positioning block 5 is arranged in the through hole 6, and the positioning block 5 can slide along the inner wall of the through hole 6, and the small wedge block 2 is provided with a first groove 7. The first groove 7 is used to limit the positioning block 5 in the through hole 6. A bead 11 is provided on both sides of the wedging block 1, and a second concave is provided on the bead 11. Groove 12, the second groove 12 is used to limit the positioning block 5 in the through hole 6, a core-pulling block 8 is provided under the wedg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com