Airlift internal loop slurry-bed reactor

A technology of reactor and slurry bed, which is applied in the field of slurry bed circulation reactor, can solve the problems of hindering the descending circulation of slurry, high energy consumption of separation device, and affecting reaction efficiency, so as to achieve good reaction and separation effect and avoid mist Entrainment, the effect of improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a more specific understanding of the technical content, characteristics and effects of the present invention, now in conjunction with the accompanying drawings, the present invention is described in detail as follows:

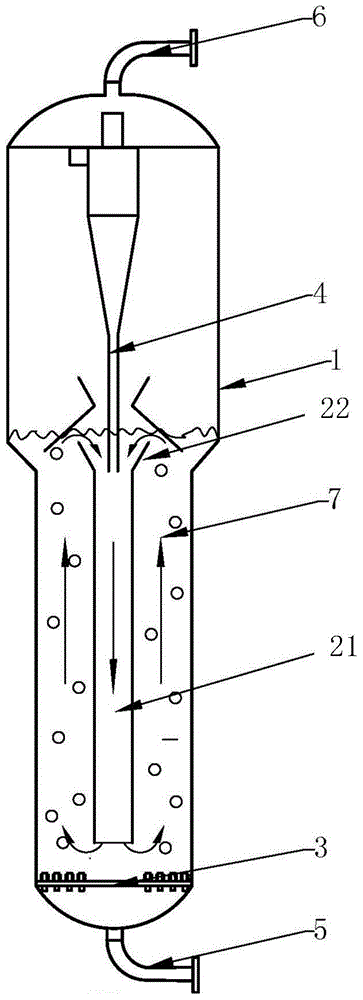

[0034] The slurry bed reactor of the present embodiment is used for carrying out Fischer-Tropsch synthesis reaction, and the axial height of this reactor is 35 meters, and diameter is 1.2 meters, and structure is as follows figure 1 As shown, it includes a shell 1 , a draft tube 2 , a gas distributor 3 , a gas-liquid separation device 4 , an inlet 5 , an outlet 6 and a slurry bed 7 . in:

[0035] The housing 1 is made of stainless steel and has an inner diameter of 1.2 meters. A gas-liquid separation device 4 , a draft tube 2 and a gas distributor 3 are sequentially arranged inside the housing 1 from top to bottom.

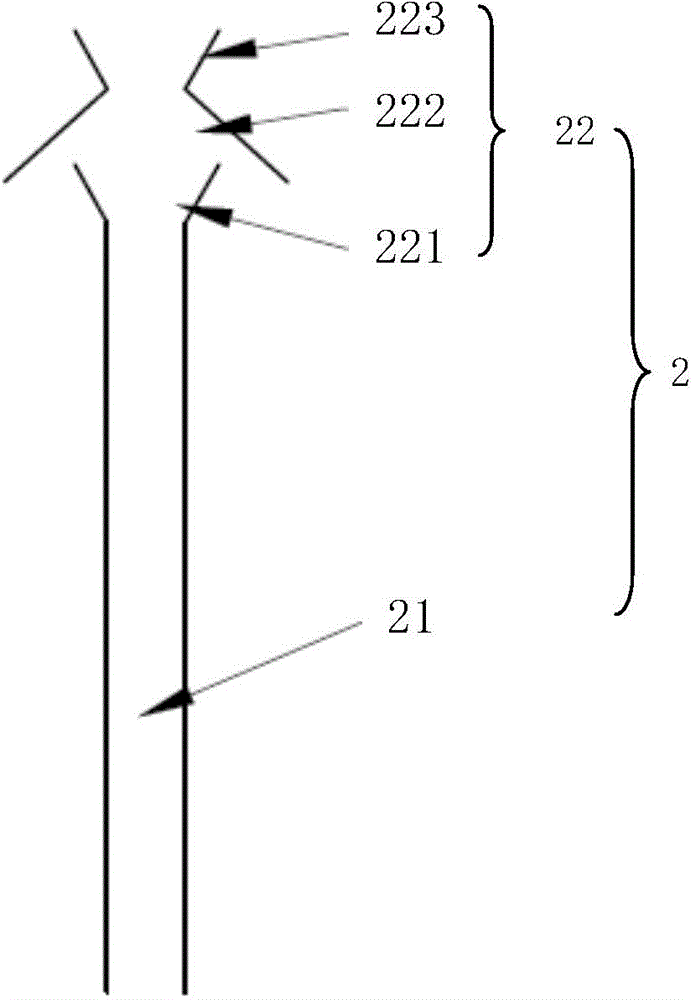

[0036] The structure of the guide tube 2 is as figure 2 As shown, it is divided into two parts, the lower straight cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com