Reaction vessel negative pressure rectification fuzzy control method

A technology of fuzzy control and negative pressure distillation, which is applied in the direction of fluid pressure control, electric fluid pressure control, non-electric variable control, etc., can solve the problems of slow operation speed, sacrifice of system stability, serious hysteresis, etc., to achieve The effect of improving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

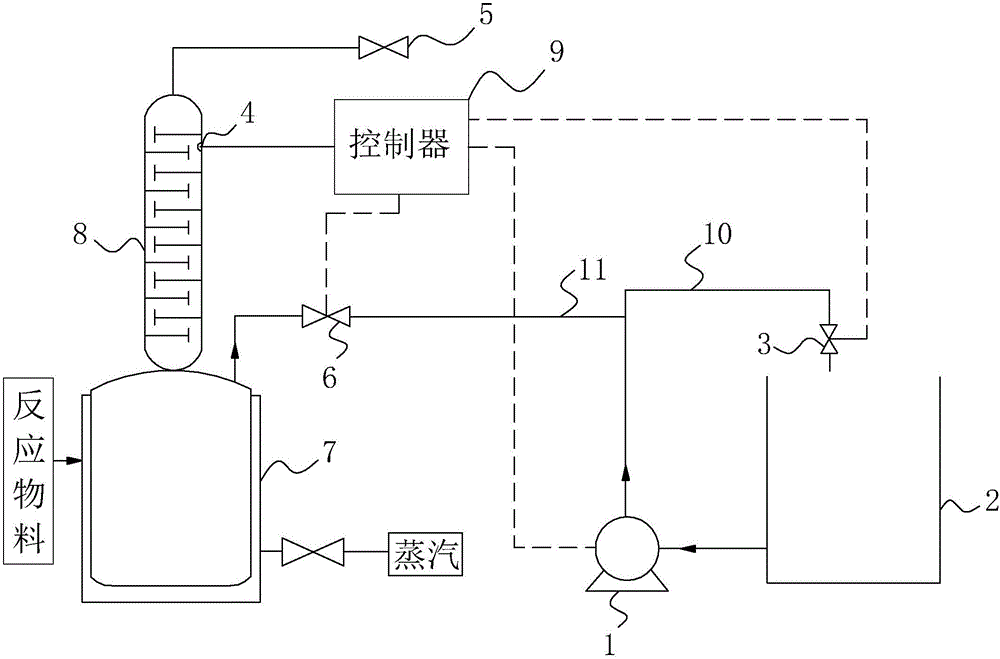

[0039] Such as figure 1 As shown, the connection mode of the negative pressure rectification of the reactor includes a negative pressure device 1 and a water tank 2, and a reactor 7 for accommodating the reaction material to heat and evaporate the reaction material, wherein the negative pressure device 1 and the water tank 2 Connect through the pipeline 10, and the reaction kettle 7 is connected to the pipeline 10 between the negative pressure device 1 and the water tank 2 through the pipeline 11; the negative pressure device 1 is a water pump that can run under the drive of the motor, and the water pump is driven by the motor The water in the water tank 2 is extracted at a high speed, and the water is sent back to the water tank through the pipeline 10, thereby forming a circulating water pipeline. The high-speed flowing water will take away the air in the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com