Single-rod spiral drying extruder

A squeeze dryer and screw technology, applied in the field of drying equipment, can solve the problems of no water guide groove, slow drainage speed, no water guide groove in the drain hole, etc., and achieve the effect of reducing the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

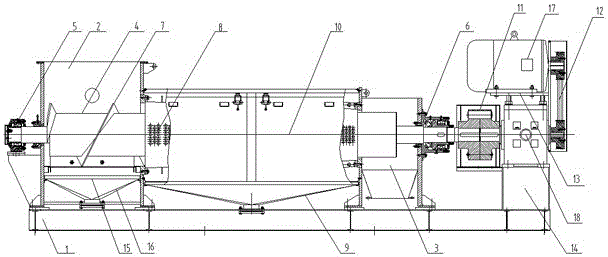

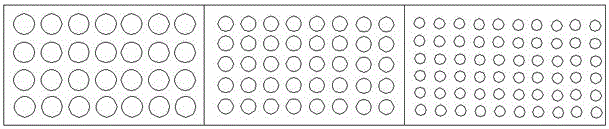

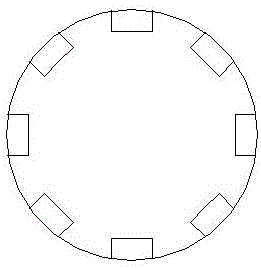

[0016] A single-rod screw squeezer, including machine base 1, feed box 2, discharge box 3, screw spindle 4, water filtration system and transmission system, the squeeze dryer is feed box 2 from left to right , water filter mechanism, discharge box 3 and transmission system, the screw main shaft 4 is located in the feed box 2, water filter mechanism and discharge box 3, one end is connected with the front bearing seat 5, and the other end is connected with the rear bearing seat 6 , the screw main shaft 4 is provided with a helical impeller 7, the water filtration mechanism includes a dewatering screen group, a dewatering screen drop bucket 9 and a waterproof cover 10, the transmission system includes a motor 17 and a reducer 18, and the dewatering screen group consists of several The dewatering screen 8 is composed of a single piece of dewatering screen 8. There are several dewatering holes on the dewatering screen 8. Water guide grooves are arranged on the dewatering holes. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com